SiCNO-based piezoresistive thin film system and preparation method thereof

A technology of film and base pressure, applied in the field of SiCNO-based piezoresistive film system and its preparation, can solve problems such as unreported, and achieve the effects of good adhesion, controllable composition, and low temperature of composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

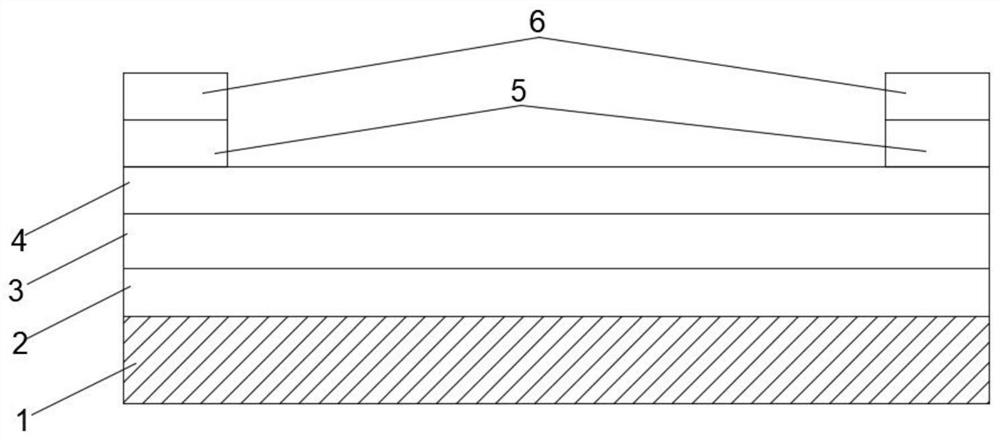

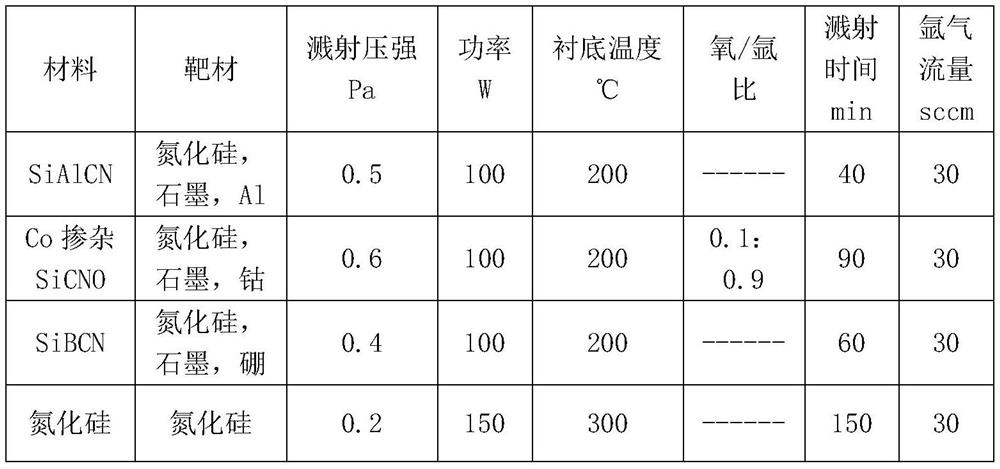

[0022] Embodiment: A SiCNO-based piezoresistive film system, including a stainless steel substrate 1, on which a silicon nitride film layer 2, a SiBCN film layer 3, and a Co-doped SiCNO film layer 4 are sequentially arranged, and a Co-doped SiCNO film layer 4 is provided with an electrode 6 via a SiAlCN thin film layer 5 .

[0023] The silicon nitride film layer has a thickness of 1-5 microns, preferably 2 microns, as an insulating layer.

[0024] The SiBCN thin film layer has a thickness of 500-700nm, preferably 600nm, and is used as an intermediate layer to enhance the bonding strength of the interface.

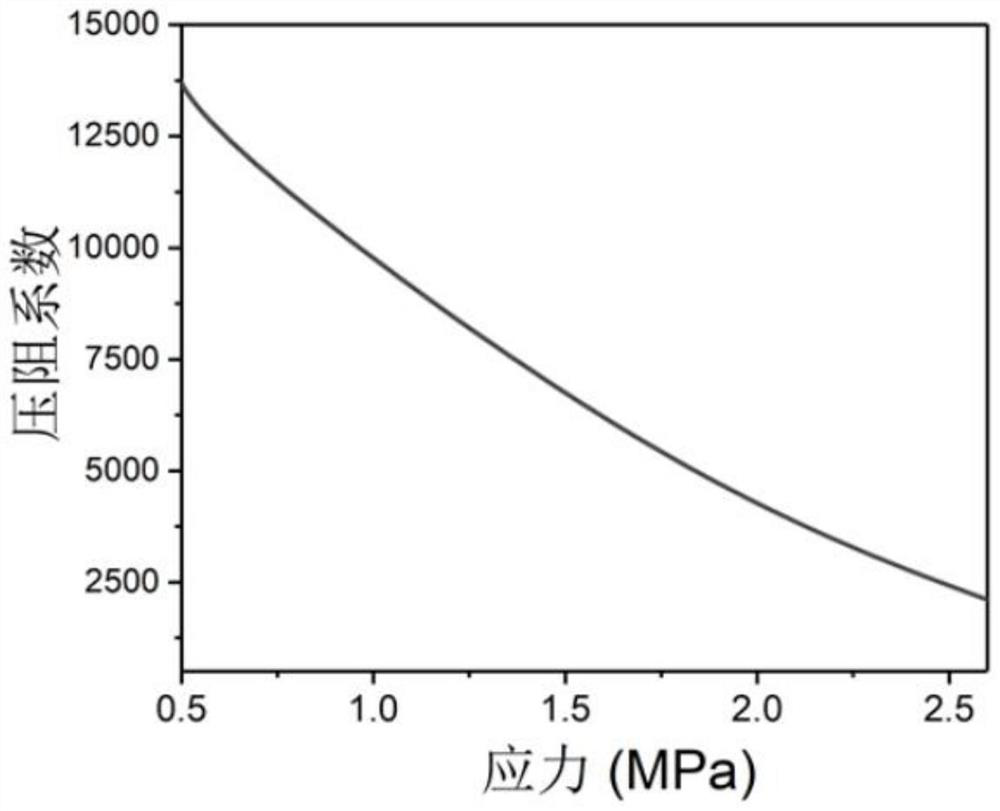

[0025] The thickness of the Co-doped SiCNO thin film layer is 800-1000nm, and the optimum is 900nm. As the main pressure-sensitive material, it has the characteristics of large piezoresistive coefficient and high temperature resistance.

[0026] The thickness of the SiAlCN film layer is 100-300nm, preferably 200nm, which is used to enhance the adhesion between the piezores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com