Sensitive resistance pressure sensor chip and processing method thereof

A pressure sensor and sensitive resistor technology, applied in the field of microelectronics, to achieve the effect of good linearity, stable chemical properties and large piezoresistive coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

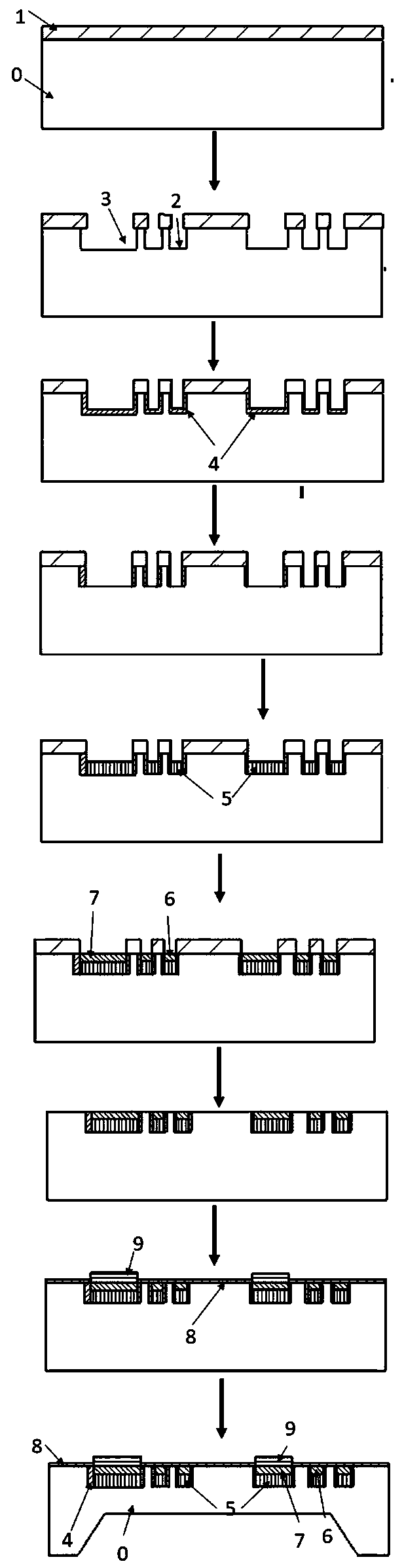

Method used

Image

Examples

Embodiment Construction

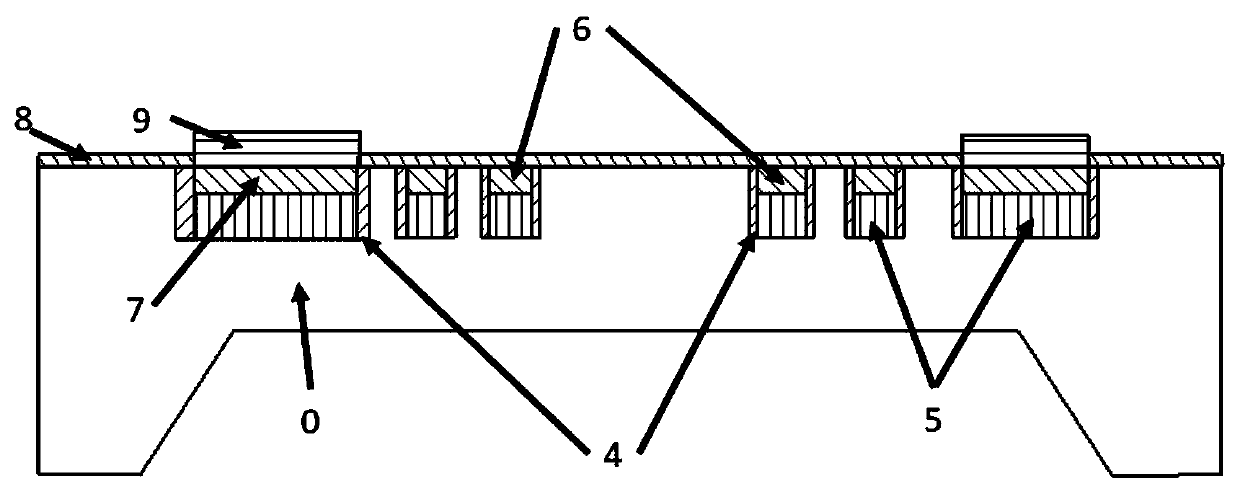

[0042] Depend on image 3 As shown, 0 in the figure is a single-crystal silicon substrate, and a silicon diaphragm is processed on the single-crystal silicon substrate layer 0, and 7 is a bonding pad area; a diamond sensitive resistor 5 is arranged inside the silicon diaphragm, and the silicon diaphragm A layer of oxide layer 4 for insulation between the diamond sensitive resistor and the substrate is separated from the side wall of the diamond sensitive resistor; the connection layer between the diamond sensitive resistor 5 and the silicon diaphragm is used to isolate the sensitive resistor from the silicon diaphragm Intrinsic Diamond 5. A silicon nitride layer 8 is also covered on the surface of the single crystal silicon substrate.

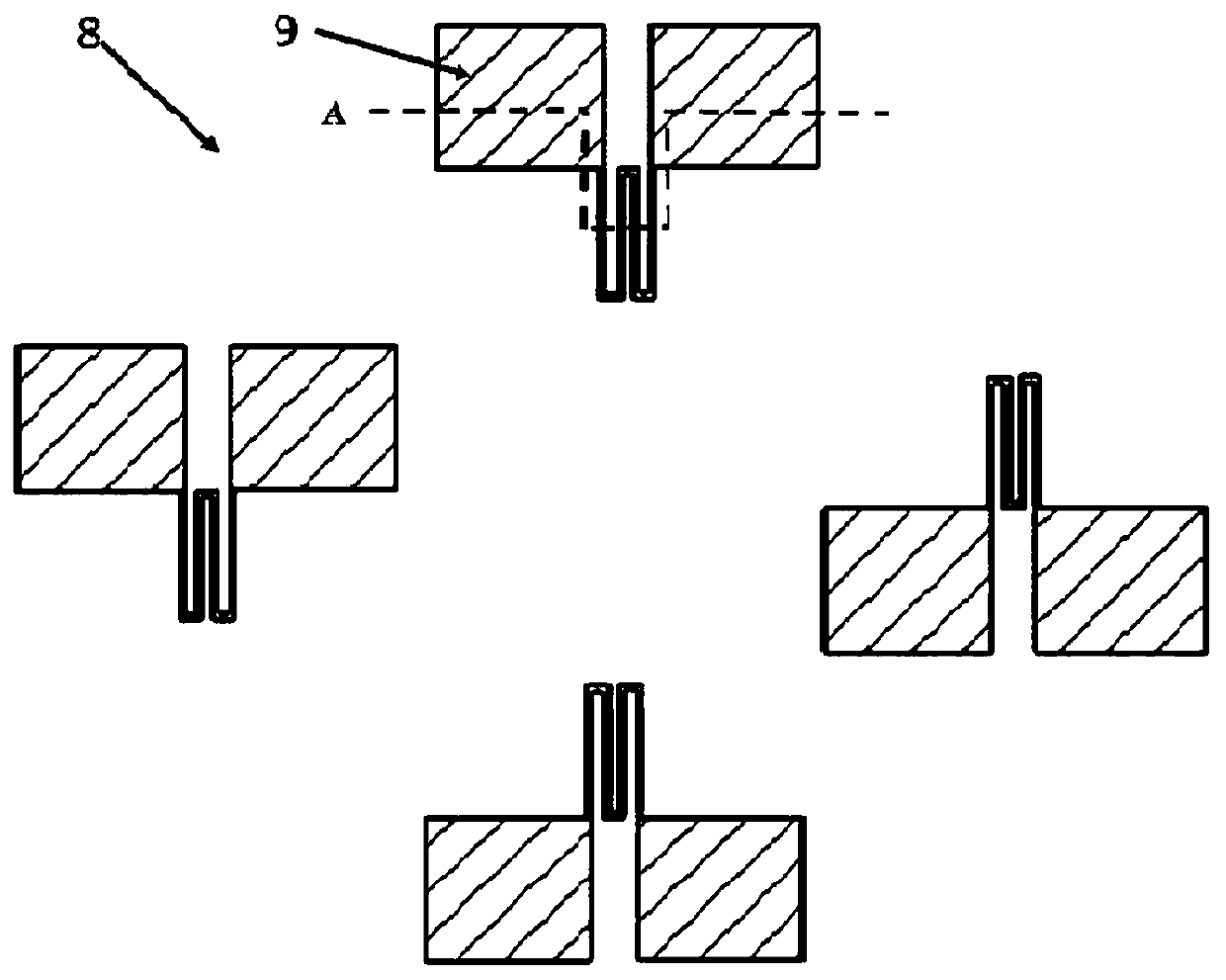

[0043] A layer of titanium gold electrode 9 for conducting electricity is connected above the diamond sensitive resistor 6 , and the cross-sectional structure at the bonding pad area 7 is consistent with that of the diamond sensitive resistor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com