Flame-retardant polyamide fabric and preparation method thereof

A fabric and nylon technology is applied in the field of flame retardant nylon fabric and its preparation, which can solve the problems of nylon degradation and deep color, and achieve the effects of less environmental pollution, simple production process and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of flame-retardant nylon fabric of the present embodiment, described preparation method comprises the following steps:

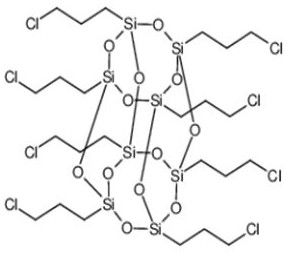

[0025] (1) Reaction of chloropropyl-POSS with acrylamide: Dissolve 6g of chloropropyl-POSS and 1.5g of triethylamine in 150mL of tetrahydrofuran in a four-neck flask, stir in an ice bath and pass through N 2 For protection, dissolve 5g of acrylamide in 100mL of tetrahydrofuran, add the tetrahydrofuran dissolved in acrylamide dropwise into the tetrahydrofuran dissolved in chloropropyl, the rate of addition is 1 drop / second, after the addition is completed, react in an ice bath at constant temperature, and the reaction time is: After 7 hours, after the reaction was completed, suction filtration under reduced pressure, rotary evaporation, and drying gave the POSS compound containing double bonds.

[0026] (2) Polymerization reaction: Weigh 2 grams of the double bond-containing POSS compound prepared in step (1), dissolve it i...

Embodiment 2

[0029] A kind of preparation method of flame-retardant nylon fabric of the present embodiment, described preparation method comprises the following steps:

[0030] (1) Reaction of chloropropyl-POSS with acrylamide: Dissolve 5g of chloropropyl-POSS and 1g of triethylamine in 150mL of tetrahydrofuran in a four-neck flask, stir in an ice bath and pass through N 2 For protection, dissolve 4g of acrylamide in 100mL of tetrahydrofuran, add the tetrahydrofuran with acrylamide solution into the tetrahydrofuran with chloropropyl group dropwise, the rate of addition is 1 drop / second, after the addition is completed, react in an ice bath at constant temperature, and the reaction time is: After 5 hours, after the reaction was completed, vacuum filtration, rotary evaporation, and drying were performed to obtain a POSS compound containing a double bond.

[0031] (2) Polymerization reaction: Weigh 1 gram of the double bond-containing POSS compound prepared in step (1), dissolve it in 50 mL o...

Embodiment 3

[0034] A kind of preparation method of flame-retardant nylon fabric of the present embodiment, described preparation method comprises the following steps:

[0035] (1) Reaction of chloropropyl-POSS with acrylamide: Dissolve 7g of chloropropyl-POSS and 2g of triethylamine in 150mL of tetrahydrofuran in a four-neck flask, stir in an ice bath and pass through N 2For protection, dissolve 6g of acrylamide in 100mL of tetrahydrofuran, add the tetrahydrofuran dissolved in acrylamide dropwise into the tetrahydrofuran dissolved in chloropropyl group, and the dropping rate is 1 drop / second. After 9 hours, after the reaction was completed, suction filtration under reduced pressure, rotary evaporation, and drying gave the POSS compound containing double bonds.

[0036] (2) Polymerization reaction: Weigh 3 grams of the double bond-containing POSS compound prepared in step (1), dissolve it in 50 mL of dimethylformamide; add 200 mL of distilled water to a four-neck flask, add 12 g of 2-acryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com