Lithium metal negative electrode and lithium metal battery comprising same

A lithium metal negative electrode and lithium metal battery technology, applied in the direction of lithium batteries, negative electrodes, battery electrodes, etc., can solve problems such as fire and explosion, shortened life of lithium metal batteries, internal short circuit of lithium metal batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

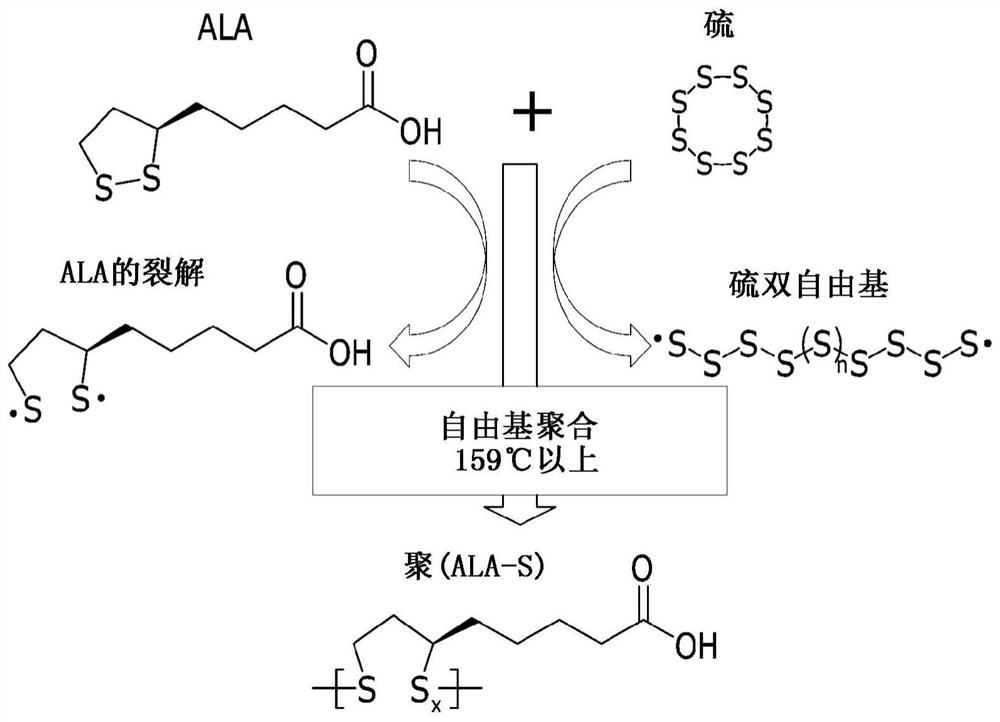

[0108] (1) Preparation of poly(ALA-S)

[0109] Preparation of α-lipoic acid (ALA) powder and sulfur molecule (S 8 ) The weight ratio of the powder is each mixture of 8:2 (Example 1), 5:5 (Example 2) and 3:7 (Example 3), and then the internal temperature is controlled at 160 ° C with an inert gas atmosphere Heat treatment in the reactor for 3 hours.

[0110] The polymers thus obtained are collectively referred to as poly(ALA-S). In addition, according to the mixing ratio of raw materials, poly(ALA:S 8 )_x:y, where x:y corresponds to ALA and S in the manufacturing raw materials 8 weight ratio. Specifically, poly(ALA:S 8 )_8:2 is the polymer of Example 1, poly(ALA:S 8 )_5:5 is the polymer of Example 2, poly(ALA:S 8 )_3:7 is the polymer of Example 3.

[0111] (2) Preparation of a separator surface coated with poly(ALA-S)

[0112] Three separators (width: 4.5 cm*length: 4.5 cm*thickness: 25 μm, porosity: 41% by volume) made of polypropylene (pp) material were prepared....

experiment example 1

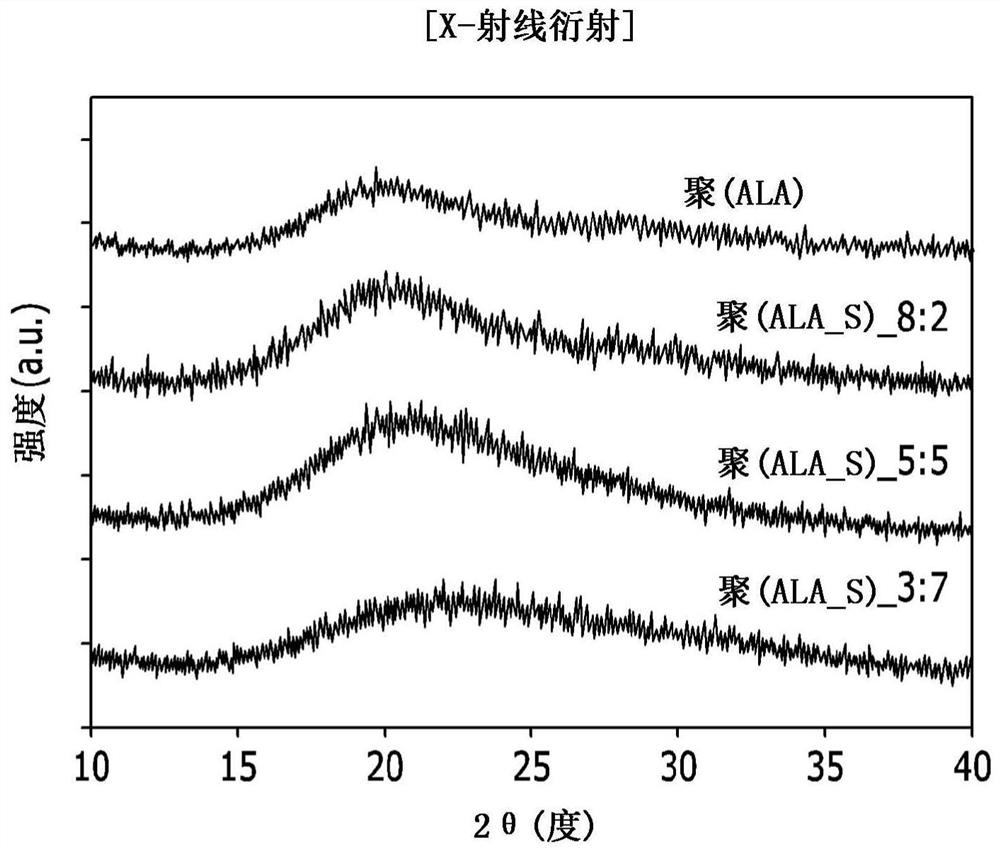

[0143] Experimental Example 1: Evaluation of the chemical formula and structure of the polymer (poly(ALA-S)) of Examples 1 to 3

[0144] 1) Elemental analysis

[0145] The polymers (poly(ALA-S)) of Examples 1 to 3 and the polymer of Comparative Example 1 (poly(ALA)) were respectively analyzed by an elemental analyzer (EA), and the results are shown in Table 1 below.

[0146] [Table 1]

[0147]

[0148] From Table 1, the chemical formulas of the polymer (poly(ALA-S)) of Examples 1 to 3 and the polymer of Comparative Example 1 (poly(ALA)) could be determined. It was confirmed that the chemical formula of poly(ALA) obtained by heat-treating only ALA (Comparative Example 1) was C 8 h 13.88 o 2.10 S 1.93 , and its sulfur mole fraction corresponds to a value close to the theoretical value of 2.

[0149] On the other hand, for ALA and S 8 In the poly(ALA-S) (Examples 1 to 3) obtained by heat-treating the mixture of C 8 h 13.10 o 1.86 S 4.11 (Example 1), C 8 h 13.1...

experiment example 2

[0153] Experimental example 2: the membrane of embodiment 1 to 3 (poly(ALA: S 8 )_x:y_ppx2) surface observation and ion conductivity evaluation price

[0154] 1) Surface observation

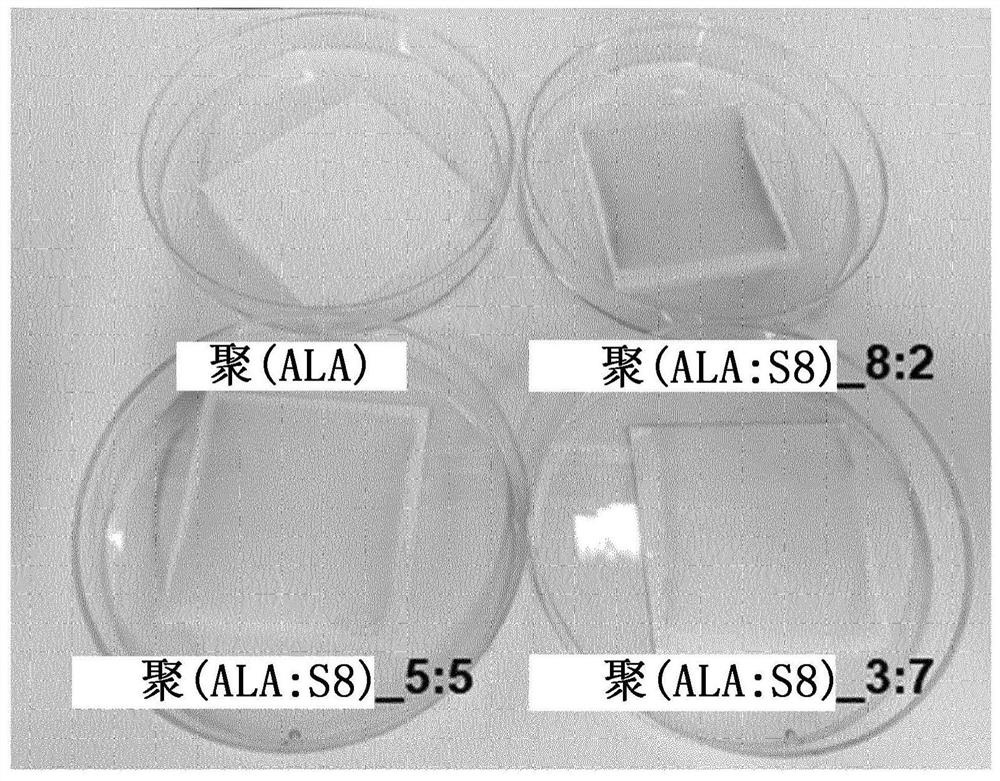

[0155] For the separator (poly(ALA:S8)_x:y_ppx2) of Examples 1 to 3 and the separator (poly(ALA)_ppx2) of Comparative Example 1, take pictures with a digital camera (Galaxy S9) respectively, as shown in Figure 3a , and then photographed with a scanning electron microscope (SEM), shown in Figure 3b middle.

[0156] exist Figure 3a and 3b , it can be seen that both poly(ALA) (Comparative Example 1) and poly(ALA-S) (Examples 1 to 3) can be uniformly coated on one surface of the separator.

[0157] 2) Ionic conductivity analysis

[0158] For the membranes of Examples 1 to 3 (poly(ALA:S 8 )_x:y_ppx2) and the diaphragm (poly(ALA)_ppx2) of Comparative Example 1, using a SUS symmetrical cell to analyze the ionic conductivity.

[0159] Specifically, for the SUS symmetric cell manufactured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com