Concrete doped with dolomitic rock powder, and preparation method thereof

A rock powder and concrete technology, which is applied in the field of concrete mixed with dolomite powder and its preparation, can solve the problem that the flow properties and later mechanical properties of concrete mixture are low, mine waste cannot be effectively utilized, and the use of dolomite powder is restricted. and other problems, to achieve the effect of high impact strength, small wear and low crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0047] The preparation method of modified polypropylene fiber is:

[0048] (1) Disperse 30%wt nano-titanium nitride in ethylene glycol, mix terephthalic acid and antimony trioxide uniformly and add to the polymerization kettle, the quality of ethylene glycol, terephthalic acid, antimony trioxide The ratio is 1:2.75:0.02. After the polymerization tank is sealed, pressurize to 0.25MPa, heat up to 250°C, stir at 100r / min, and perform esterification for 1.5h to obtain an intermediate product;

[0049] (2) Perform polycondensation treatment on the intermediate product, increase the vacuum degree to 20MPa, control the temperature at 270°C, adjust the stirring speed to 240r / min, and react for 1.5h to obtain a nano-titanium nitride / PET polycondensate;

[0050] (3) The pressure is adjusted back to normal pressure, the temperature is adjusted to 50°C, the stirring speed is adjusted to 130r / min, and the polypropylene resin accounting for 35% of the total amount of nano-titanium nitride / P...

Embodiment 1

[0053] A kind of concrete mixed with dolomite powder is prepared by the following method:

[0054] Step 1: Take 700kg of medium sand, 900kg of gravel and 100kg of water and mix them according to the set ratio, add them to the mixer and stir evenly to form a premix;

[0055] Step 2: Immediately add 150kg of cement, 30kg of fly ash, 90kg of granulated blast furnace slag powder, 30kg of dolomite powder, 5kg of polycarboxylate superplasticizer and the remaining 50kg of water to the premix in the mixer and continue stirring to form a mixture evenly.

[0056] Step 3: After the mixture is evenly stirred, the concrete mixture mixed with dolomite powder is prepared.

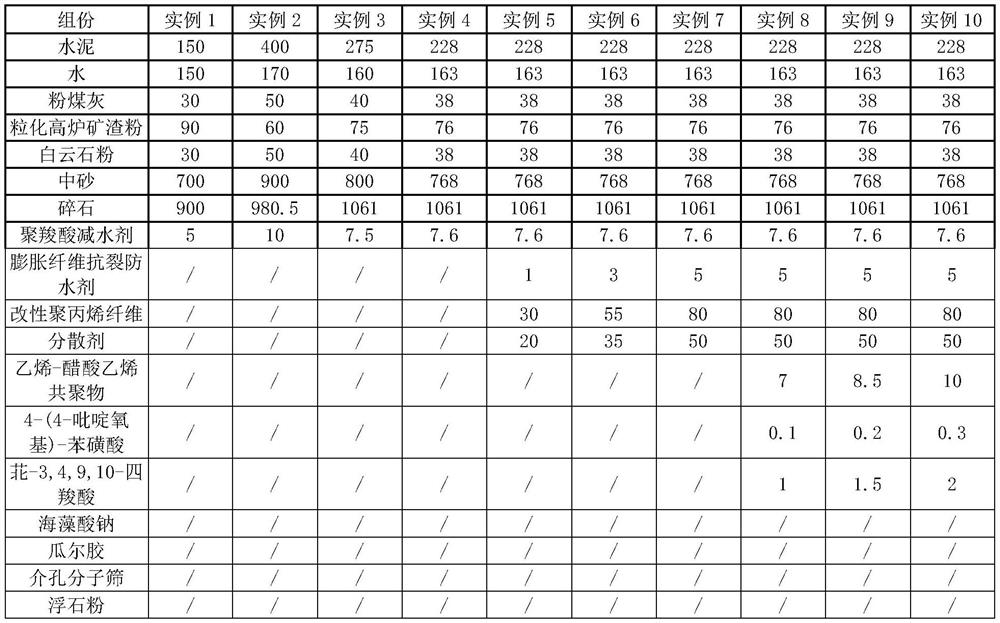

[0057] Compared with Example 1, the remaining examples differ in that the raw materials and the amount of raw materials added are different, as shown in Table 1 and Table 2.

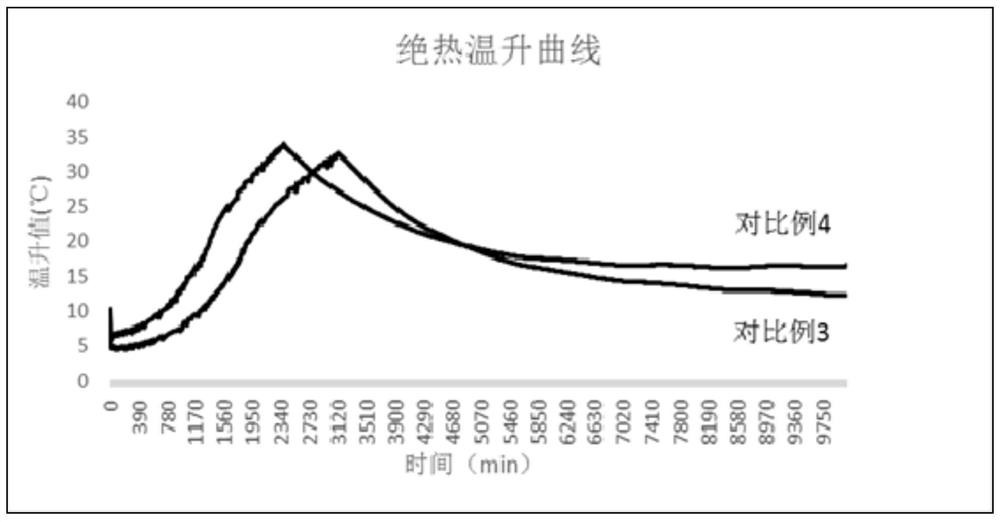

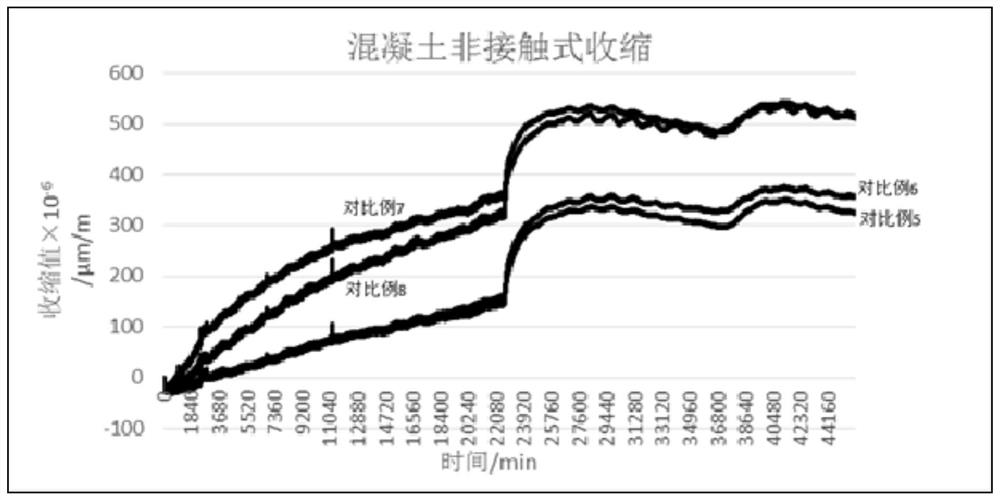

[0058] Components and component additions of table 1 embodiment 1-10

[0059]

[0060] Components and component additions of table 2 embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com