Water-based antibacterial ultra-matte scratch-resistant gloss oil applied to PVC film and preparation method of water-based antibacterial ultra-matte scratch-resistant gloss oil

An ultra-matte scratch-resistant, ultra-matte scratch-resistant technology, used in biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve low-gloss wear resistance, chemical resistance, organic antibacterial The agent is not resistant to high temperature processing, does not have broad-spectrum antibacterial properties, etc., to achieve the effects of excellent scratch resistance, fine and smooth hand feel, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

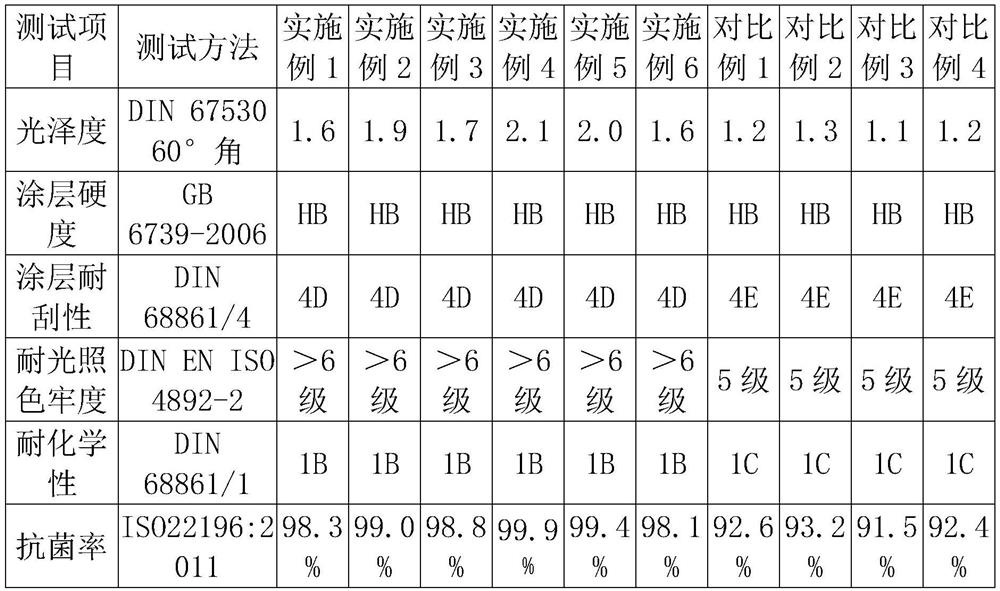

Examples

Embodiment 1

[0034] A water-based antibacterial super-dumb scratch-resistant varnish applied to PVC films, the water-based antibacterial super-dumb scratch-resistant varnish includes A component, B component, C component, D component and diluent, the A group The mass ratio of component, B component, C component, D component and diluent is 95:2:3:0.5:5, wherein, A component is made according to the following raw materials in parts by weight: 90 parts of water-based polyurethane resin, 1 part of anti-scratch agent, 0.1 part of defoamer, 0.1 part of wetting agent and 0.1 part of pH regulator, the B component is multifunctional aziridine, and the C component is hydrophilic Water-based aliphatic polyisocyanate, the D component is a nano inorganic antibacterial agent, the diluent is alcohol, and the alcohol content in the alcohol is greater than 99.3%.

[0035] Specifically, the solid content of the self-dulling silicone-modified waterborne polyurethane resin involved in the present invention is...

Embodiment 2

[0042] A kind of preparation method of the water-based antibacterial ultra-dumb anti-scratch varnish applied on the PVC film in this embodiment is the same as that of Embodiment 1, and will not be repeated here. The difference is that the A component in the present embodiment is as follows Raw materials in parts by weight: 95 parts of self-dulling silicone modified water-based polyurethane resin, 3 parts of anti-scratch agent, 1 part of defoamer, 1 part of wetting agent and 0.5 part of pH regulator.

Embodiment 3

[0044] A kind of preparation method of the water-based antibacterial ultra-dumb anti-scratch varnish applied on the PVC film in this embodiment is the same as that of Embodiment 1, and will not be repeated here. The difference is that the A component in the present embodiment is as follows Raw materials in parts by weight: 92 parts of self-dulling silicone modified waterborne polyurethane resin, 2 parts of anti-scratch agent, 0.3 part of defoamer, 0.5 part of wetting agent and 0.3 part of pH regulator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com