High-voltage electric field low-temperature plasma cold sterilization method of instant dry-fruit foods

A low-temperature plasma and high-voltage electric field technology, which is applied in the fields of food electrical processing, food preservation, food ingredients, etc., can solve the problems of rough and uneven surface, wrinkled skin of dried fruits and vegetables, and limited sterilization and preservation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment discloses a high-voltage electric field low-temperature plasma cold sterilization method for red jujube dried fruit under different voltage intensities (power densities), and the steps are as follows:

[0031] 1) Sample pretreatment: Put the bulk red dates bought from the supermarket in a dark and humid place (temperature: 27°C, humidity: 80% RH) and take them out after 4 days. At this time, the total number of colonies is about 3.15Log / g. Weigh a certain weight (40g±1g) inside (packing box: 17cm×12cm×3.6cm), fill it with air and seal it directly for packaging.

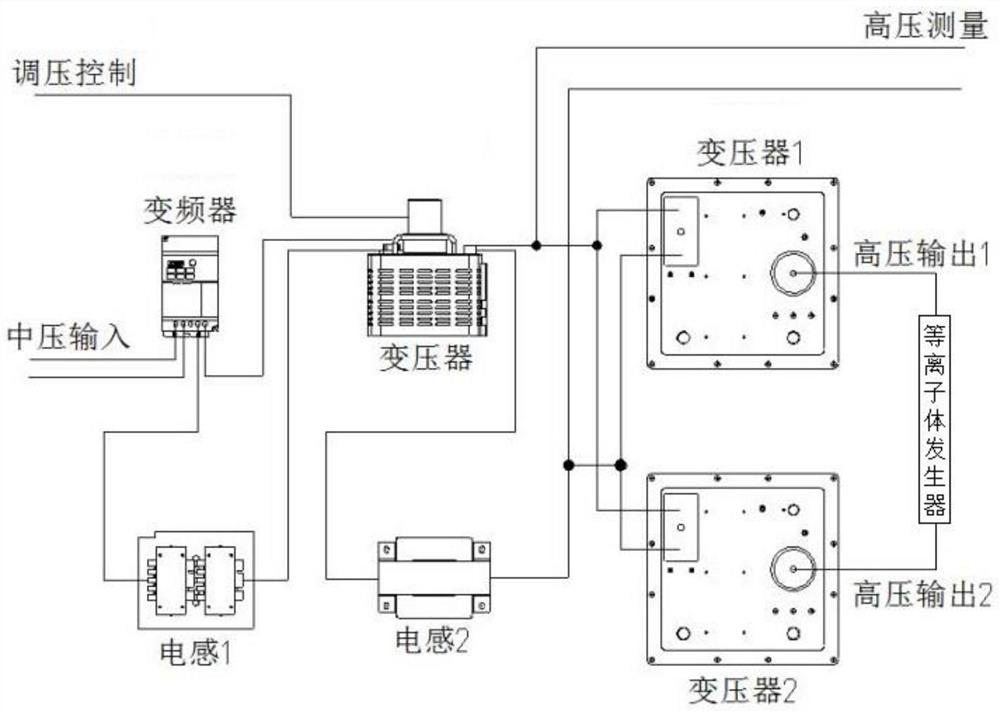

[0032] 2) Sterilization treatment: place the packaging box between the two electrodes of the high-voltage electric field low-temperature plasma sterilization device, adjust the distance between the two plates to 3.8 cm, and conduct plasma at room temperature and relative humidity of 50-80% RH Cold sterilization treatment; short-time-interval-multiple cycle sterilization method is adopted, the tr...

Embodiment 2

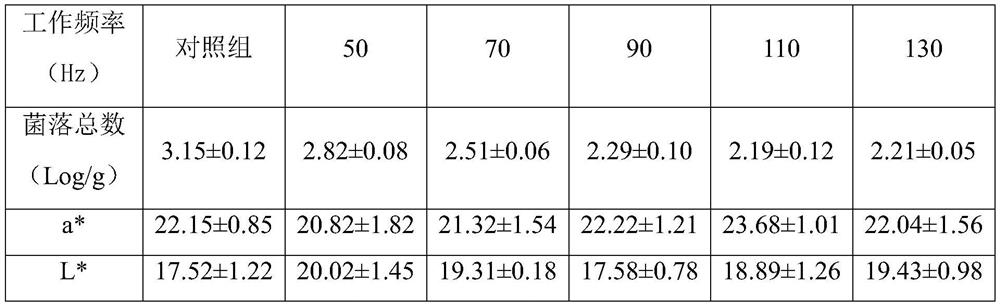

[0039] This embodiment discloses a method for cold sterilization of dried jujube fruits under high-voltage electric field and low-temperature plasma with different operating frequencies. The steps are as follows:

[0040] 1) Sample pretreatment: Put the bulk jujube bought from the supermarket in a dark and humid place (temperature: 27°C, humidity: 80% RH) for 4 days and then take it out. At this time, the total number of colonies is about 3.15Log / g. The weight (40g±1g) is in the box (box: 17cm×12cm×3.6cm), filled with air and sealed directly.

[0041] 2) Sterilization treatment: place the packaging box between the two electrodes of the high-voltage electric field low-temperature plasma sterilization device, and adjust the distance between the two plates to 3.8cm; the voltage intensity of the high-voltage electric field low-temperature plasma is 13.14kV / cm, and the power density is 11.05 w / cm 3 ;Low-temperature plasma treats the dried red dates at different operating frequenci...

Embodiment 3

[0047] Embodiment 3 discloses a high-voltage electric field low-temperature plasma response surface optimization test method for the sterilization rate of red jujube dried fruit, and the steps are as follows:

[0048] 1) Sterilization treatment: the packaging box is placed between the two electrodes of the high-voltage electric field low-temperature plasma sterilization device, and the distance between the two electrode plates is adjusted. The low-temperature plasma performs cold sterilization on the dried red dates under different treatment conditions on the response surface.

[0049] 2) Under the same conditions, the sample without plasma treatment was the control group. Detect the number of mold and yeast according to GB4789.15-2016 "National Food Safety Standard for Food Microbiology Examination of Mold and Colony Count"; according to GB 4789.3-2016 "National Food Safety Standard for Food Microbiology Examination of Coliform Count" to measure the number of coliform bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com