Fresh-cut fruit and vegetable preservative compounded by antibacterial substances produced through bacillus licheniformis, bacillus atrophaeus and bacillus amyloliquefaciens

A technology of Bacillus atrophs and Bacillus licheniformis, which can be used in the preservation of fruits and vegetables, preservation of food ingredients as antimicrobials, microorganism-based methods, etc., and can solve the problems of cancer-inducing, chronic poisoning, and teratogenic foods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

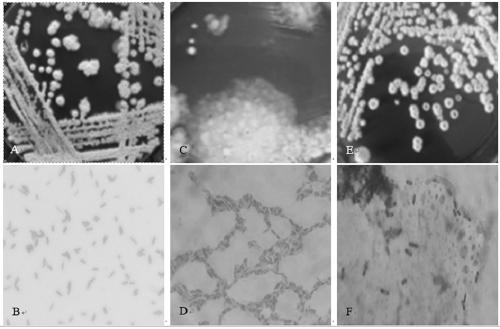

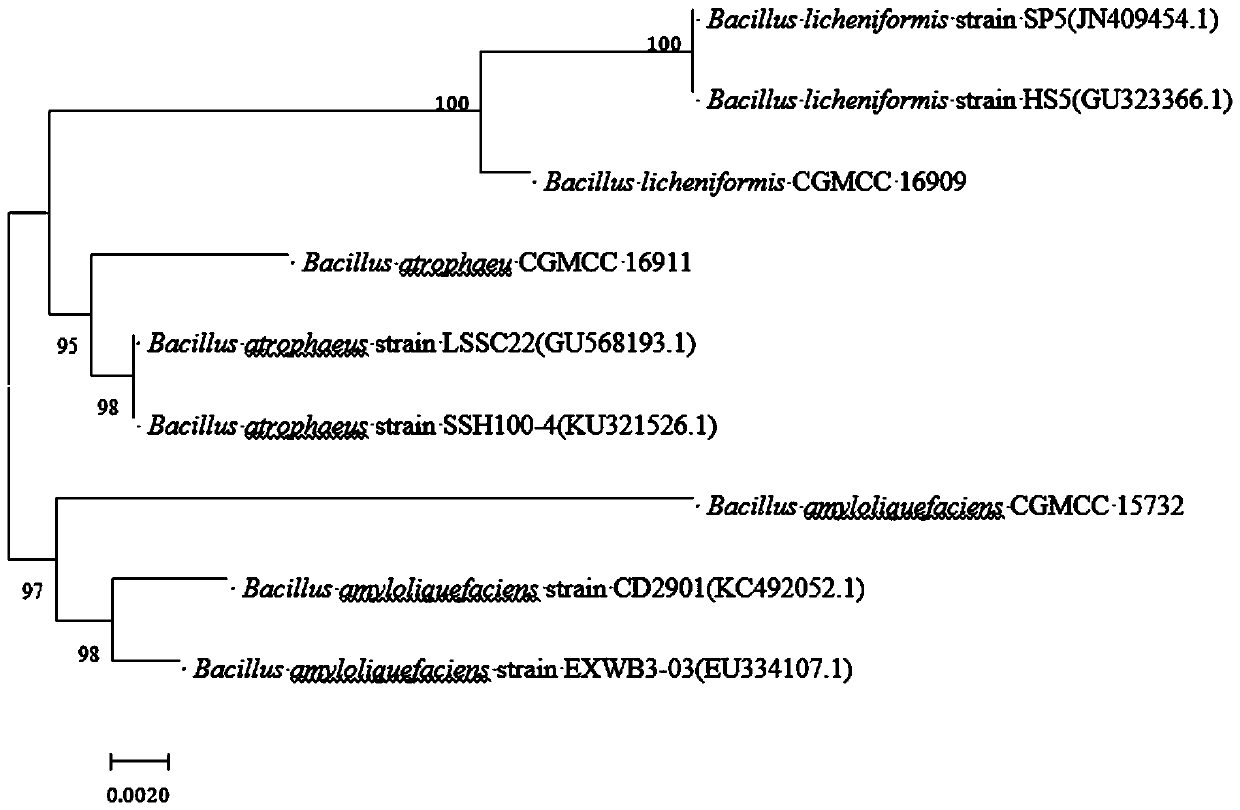

[0029] Example 1: Screening, identification and preservation of spores with high antibacterial activity

[0030] (1) Screening of spores with high antibacterial activity: Collect mash samples in the alcohol fermentation stage of Shanxi old vinegar and vinegar mash samples in the acetic acid fermentation stage, and use MRS medium for dilution and coating, and finally a total of 50 strains are isolated Bacillus. The Oxford cup inhibition zone method was used to screen it for its antibacterial activity. Among them, Bacillus 297 had a better antibacterial effect on Gram-negative bacteria, and the most significant antibacterial effect on Escherichia coli. The diameter of the inhibition zone was 20.54. mm; Bacillus sp. 1671 has a good antibacterial effect on Gram-positive bacteria, among which Staphylococcus aureus has the most significant antibacterial effect, with a diameter of 21.82 mm; Bacillus 2014 has a good antibacterial effect on spoilage molds of fruits and vegetables Among t...

Embodiment 2

[0038] Example 2: Preparation of a composite preservative for fresh-cut fruits and vegetables

[0039] The activated Bacillus licheniformis CGMCC 16909, Bacillus atrophicus CGMCC 16911, and Bacillus amyloliquefaciens CGMCC 15732 were respectively inoculated into MRS liquid medium at 5% inoculation amount. After culturing at 37℃ and 160rpm / min for 24h, 4℃ Centrifuge at 10000 r / min for 10 min, and take the supernatant; adjust the supernatant to neutral with 6mol / L HCl solution, add solid ammonium sulfate while stirring, and when the saturation reaches 80%, place in a refrigerator at 4°C overnight ; Centrifuge at 4000r / min for 20 minutes and collect the precipitate, dissolve it with pH=7.2 phosphate buffer, dialyze to remove the salt, vacuum freeze-dry, mix according to the weight ratio of 1:1:1, vacuum packaging is the composite preservation Agent.

[0040] The above-mentioned phosphate buffer preparation method is as follows: potassium dihydrogen phosphate 0.24 g, disodium hydrogen...

Embodiment 3

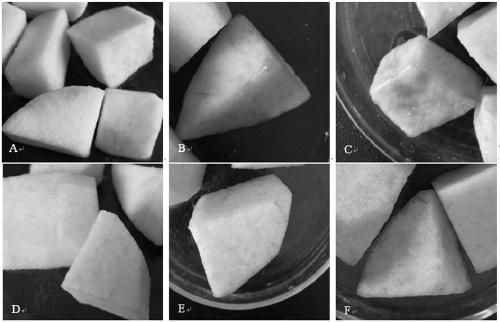

[0042] Example 3: Application of composite preservative in preservation of fresh-cut apples

[0043] The composite preservative is prepared according to the above technical scheme and applied to the preservation of fresh-cut apples. The specific implementation method is as follows:

[0044] Cut the apple into small pieces according to the shape (2cm×2cm×2cm), soak the freshly cut apple in 0.5% ascorbic acid and 1.0% citric acid (color retention agent) for 2 minutes, then take it out and drain it, and put it in a sterile plate First use a 50mL small spray can to spray 250μL of pathogenic bacteria mixture (concentration of 10 4 cfu / mL), and then evenly spray 500μL of compound preservative (concentration 1.0mg / mL), then dry it on the ultra-clean bench aseptic air, cover it with plastic wrap, and place it in a 4℃ environment to prevent common corruption during preservation. Bacteria Staphylococcus aureus, Escherichia coli, Listeria monocytogenes, Salmonella enteritidis and Shigella fle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com