Processing method of red date grains

A processing method and technology for red dates, which are applied in food preservation, fruit and vegetable preservation, grain processing and other directions, can solve the problems of easy reproduction, serious microorganisms sticking to the knife, low pulverization qualification rate, etc. Economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

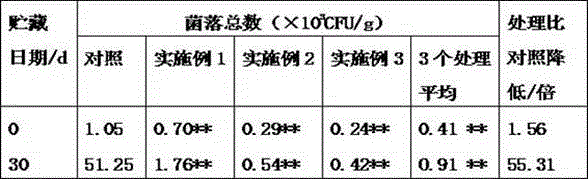

Examples

Embodiment 1

[0022] (1) Preparation of anti-adhesive antibacterial solution Place cloves and ginkgo leaves in a drying oven at 60°C to dry until the moisture content is less than 10%, crush them through a 100-mesh sieve, then mix 50g each, add 1800ml of 70% ethanol under ultrasonic conditions The extraction time was 50min, the extraction temperature was 70°C, the power was 1000W, the stirring speed was 900r / min, the filtrate was obtained by vacuum filtration, and the filtrate was diluted with 70% ethanol until the flavonoid content reached 1.5mg / ml;

[0023] (2) Pretreatment and cleaning of 1000 g of jujubes, removal of moldy and rotten fruits and impurities, and removal of pits;

[0024] (3) Soaking Take 500 g of pitted red dates, soak in 1000 g of water for 30 minutes, stop soaking when the water content reaches 20%, drain, and then use step (1) to prepare anti-sticking and antibacterial solution, soak for 15 minutes and drain;

[0025] (4) Crush the red dates treated in step (3) with a ...

Embodiment 2

[0030] (1) Preparation of anti-stick and antibacterial solution Place cloves and ginkgo leaves in a drying oven at 60°C to dry until the water content is less than 10%, crush them through a 100-mesh sieve, then mix 50g each, add 2200ml 80% ethanol in ultrasonic Under the conditions, the extraction time is 40min, the extraction temperature is 65°C, the power is 1000W, the stirring speed is 800r / min, the filtrate is obtained by vacuum filtration, and the filtrate is diluted with 80% ethanol until the flavonoid content reaches 2.0mg / ml;

[0031] (2) Pretreatment and cleaning of 1000 g of jujubes, removal of moldy and rotten fruits and impurities, and removal of pits;

[0032] (3) Soaking Take 500 g of pitted red dates, soak in 1200 g of clear water for 30 minutes, when the water content reaches 22%, stop soaking, drain, and then use step (1) to prepare anti-sticking antibacterial solution, soak for 10 minutes and drain;

[0033] (4) Crush the red dates processed in step (3) using...

Embodiment 3

[0038] (1) Preparation of anti-stick and antibacterial solution Place cloves and ginkgo leaves in a 60°C drying oven to dry until the moisture content is less than 10%, crush them through a 100-mesh sieve, then mix 50g each, add 2000ml 75% ethanol in ultrasonic Under the conditions, the extraction time is 45min, the extraction temperature is 68°C, the power is 1000W, the stirring speed is 850r / min, the filtrate is obtained by vacuum filtration, and the filtrate is diluted until the flavonoid content reaches 2.5mg / ml;

[0039] (2) Pretreatment and cleaning of 1000 g of jujubes, removal of moldy and rotten fruits and impurities, and removal of pits;

[0040] (3) Soaking Take 500 g of pitted red dates, soak in 1100 g of water for 40 minutes, stop soaking when the water content reaches 25%, and then use step (1) to prepare anti-sticking and antibacterial solution, soak for 10 minutes and then drain;

[0041] (4) Crush the jujube processed in step (3) with a nitrogen-filled frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com