Water treatment method for adsorbing humic acid in water by metal organic framework HKUST-1

A HKUST-1, metal-organic framework technology, applied in the field of environmental engineering, can solve the problems of difficult recovery of catalysts and high processing costs, and achieve fast and efficient adsorption and good regenerative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0070] 1) Preparation of HKUST-1

[0071] HKUST-1 was prepared by solvothermal method.

[0072] 2) Preparation and determination of humic acid standard solution

[0073] Prepare a 1g / L humic acid standard stock solution, dilute it into a 1-20 mg / L humic acid use solution, and use an ultraviolet spectrophotometer to measure the humic acid concentration.

[0074] 3) The specific adsorption process is implemented according to the following steps

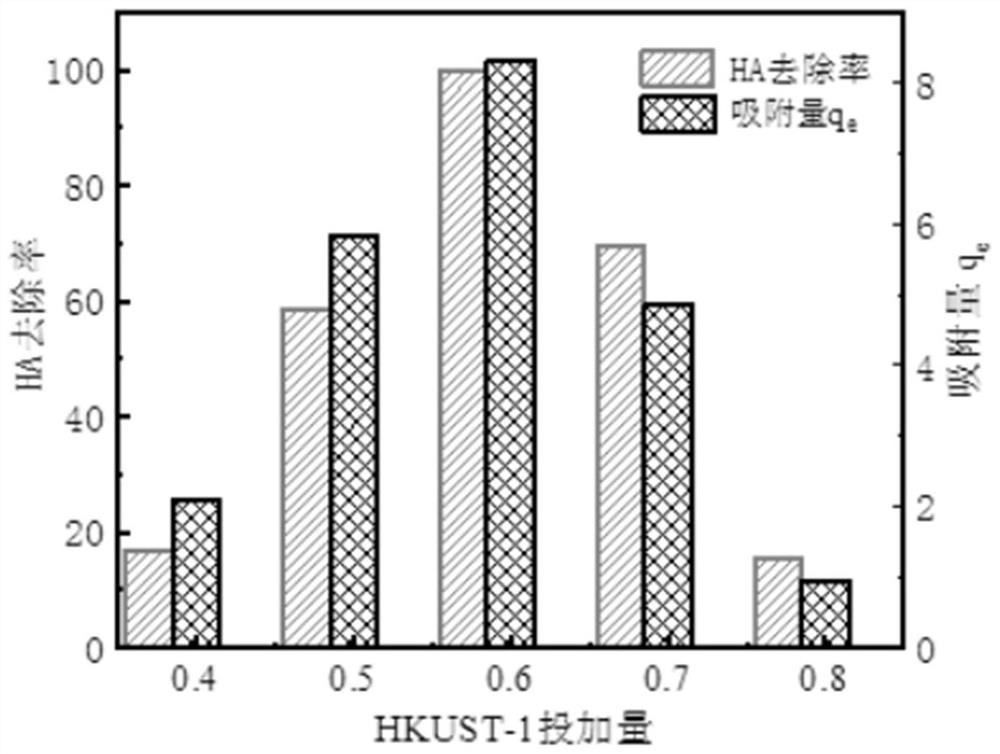

[0075] The dosage of HKUST-1 is 0.6g / L, under the conditions of temperature 298K, 313K and 333K, and oscillation intensity of 200r / min, place it in a water bath constant temperature oscillator for oscillation, absorb for 120min, and measure the adsorption equilibrium after passing through the membrane. Humic acid solution concentration Ce.

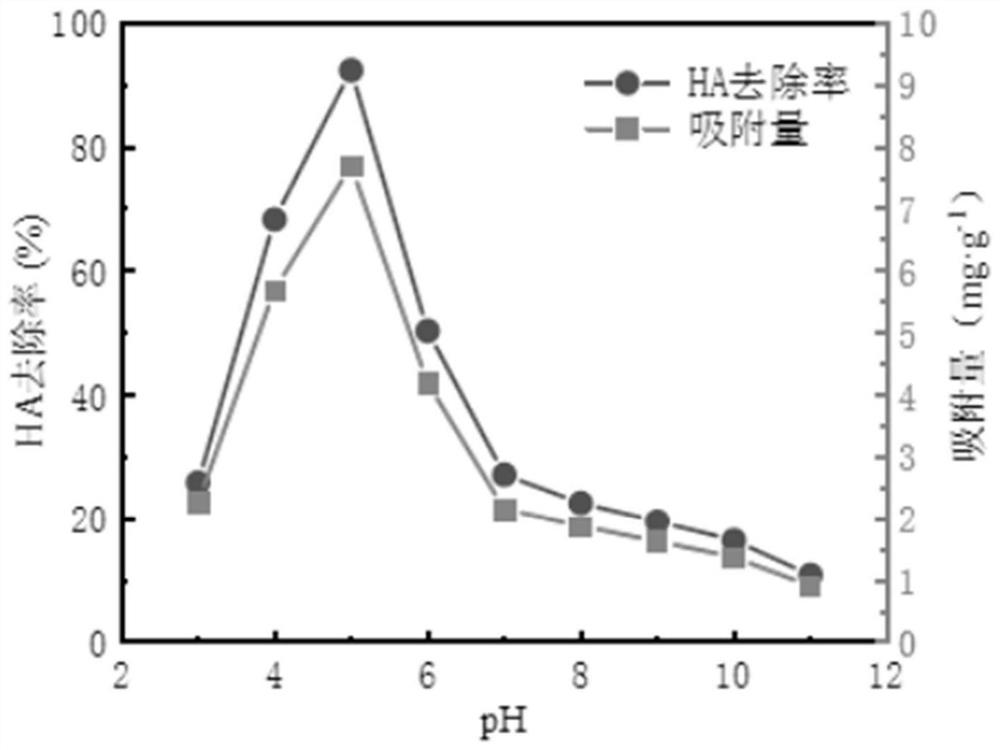

[0076] The Langmuir adsorption isotherm model can more accurately describe the adsorption process of humic acid by HKUST-1. The adsorption capacity of humic acid of HKUST-1 at 298K is 14.423mg / g...

example 2

[0078] 1) Preparation of HKUST-1

[0079] HKUST-1 was prepared by solvothermal method.

[0080] 2) Preparation and determination of humic acid standard solution

[0081] Prepare a 1g / L humic acid standard stock solution, dilute it into an 8mg / L humic acid use solution, and use an ultraviolet spectrophotometer to measure the humic acid concentration.

[0082] 3) The specific adsorption process is implemented according to the following steps

[0083] The dosage of HKUST-1 is 0.6g / L, the initial concentration of HA is fixed at 8mg / L, and the pH value of the solution is adjusted to 5. Under the condition of shaking intensity of 200r / min, adsorption of 2, 5, 20, 30, 40, 90 , 120, 240 and 400min after sampling, after passing through the membrane, measure the concentration of humic acid solution.

[0084] 10 minutes before the start of the reaction, the adsorption rate of HKUST-1 to humic acid is fast and linear, and the highest adsorption capacity can reach 5.856mg / g (298K), 6.74...

example 3

[0086] 1) Preparation of HKUST-1

[0087] HKUST-1 was prepared by solvothermal method.

[0088] 2) Preparation and determination of humic acid standard solution

[0089] Prepare a 1g / L humic acid standard stock solution, dilute it into a 5mg / L humic acid use solution, and use an ultraviolet spectrophotometer to measure the humic acid concentration.

[0090] 3) The specific adsorption process is implemented according to the following steps

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com