Glass kiln and glass product production device with same

A technology for glass furnaces and glass products, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., and can solve the problems of additional investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

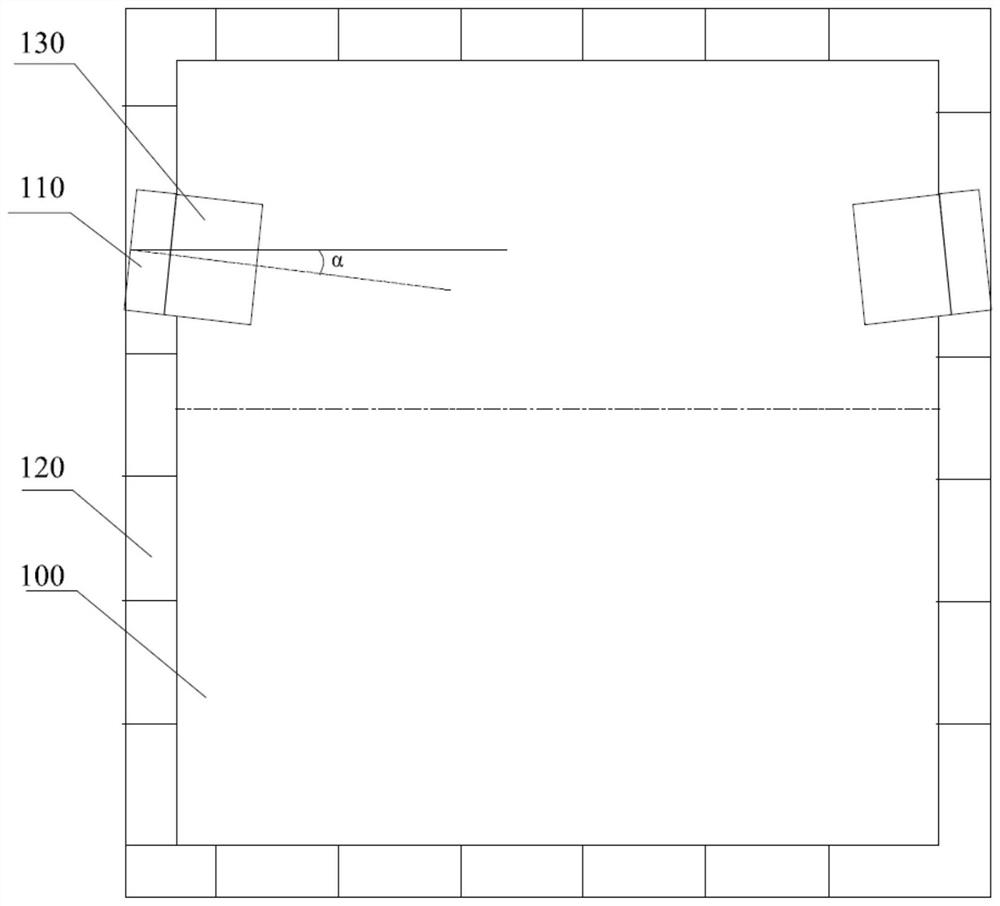

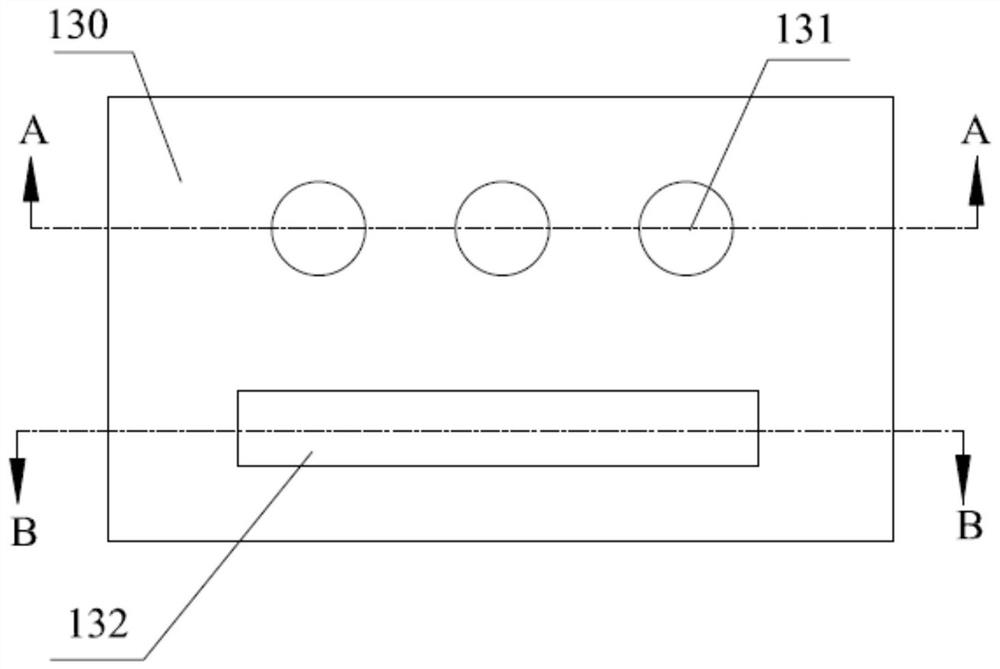

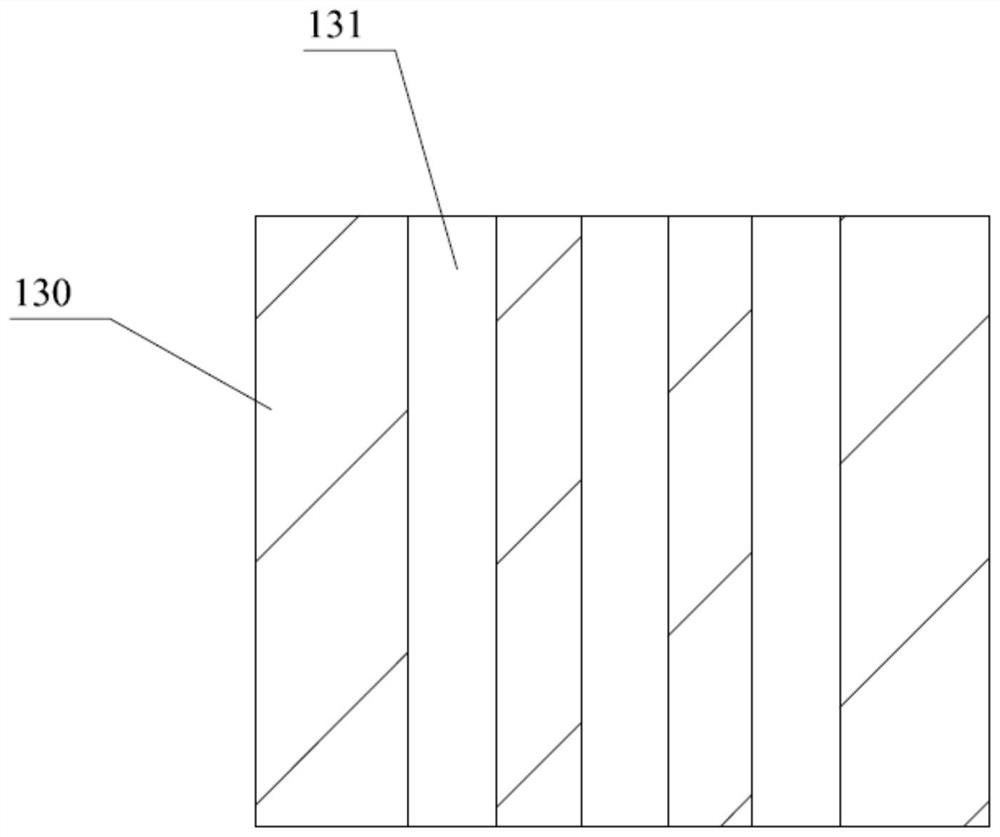

[0032] Such as Figure 1 to Figure 4 Shown is an embodiment of the glass furnace 100 of the present invention, which includes a furnace body 120 with at least two sets of parapet bricks 110. The parapet bricks 110 are equipped with nozzle bricks 130, and the nozzle bricks 130 are arranged inwardly toward the furnace body 120. The nozzle brick 130 is penetrated with a first nozzle 131 and a second nozzle 132, and the first nozzle 131 and the second nozzle 132 inject natural gas and oxygen into the furnace body 120 respectively, and the cross-sectional area of the second nozzle 132 is larger than that of the first nozzle 132. A cross-sectional area of the nozzle 131 . In this embodiment, the furnace body 120 is obtained by laying many bricks, the breast wall brick 110 is built and embedded in the brick body, and the nozzle brick 130 is installed on the breast wall brick 110 .

[0033] During the implementation of this embodiment, breast wall bricks 110 are arranged inwardly...

Embodiment 2

[0038] Such as Figure 5 Shown is an embodiment of the glass product production device of the present invention, including the glass furnace 100 as described in Embodiment 1, the forming assembly 200 for forming the glass liquid into a shape-fixed glass product 700, and the surface of the glass product 700 The polished polishing assembly 300 and the conveyor belt 400 for transporting the glass product 700, the glass furnace 100, the forming assembly 200 and the polishing assembly 300 are connected in sequence.

[0039] The glass raw material is melted in the glass furnace 100, and the molten glass enters the molding assembly 200 to cool down and finalize the shape. In industry, the molding assembly 200 is usually a mold composed of two halves, so that joint marks will be formed on the surface of the glass product 700. In addition, in the Factors such as uneven heating during the glass production process lead to different surface quality of the glass product 700 . During the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com