Rare earth oxide reinforced and toughened ceramic rock plate and preparation method thereof

A rare earth oxide, strengthening and toughening technology, applied in the field of building materials, can solve the problems of complex preparation process and insignificant improvement of mechanical properties of slabs, and achieve the effects of improved mechanical properties, easy operation, and simple adding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

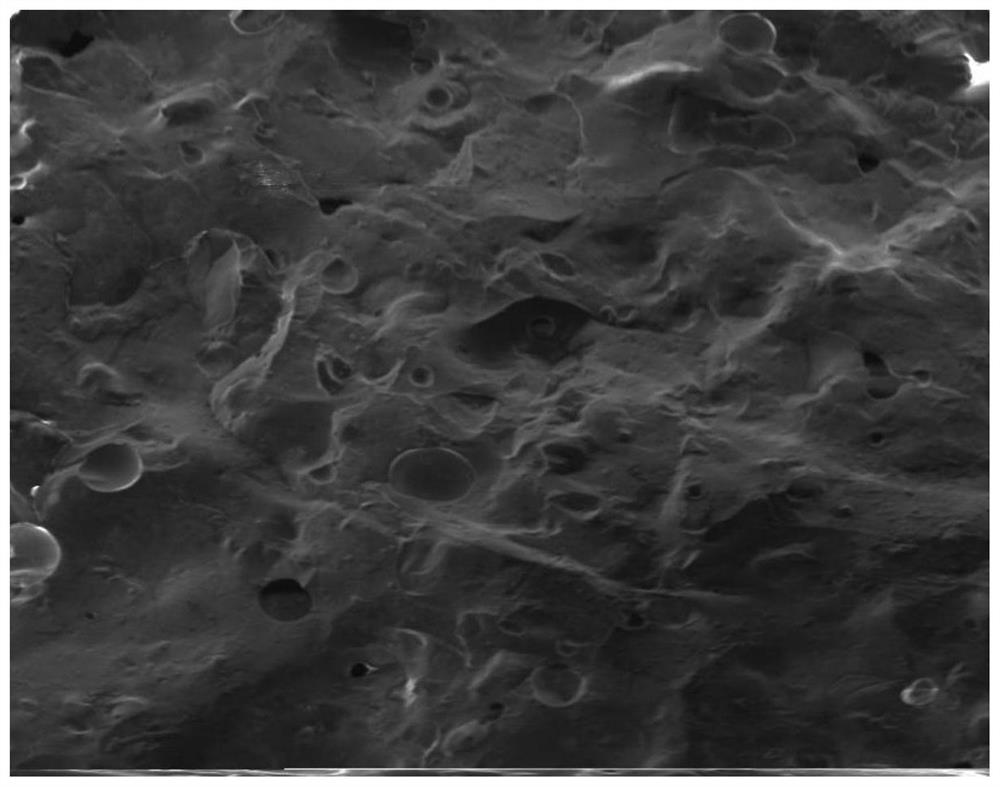

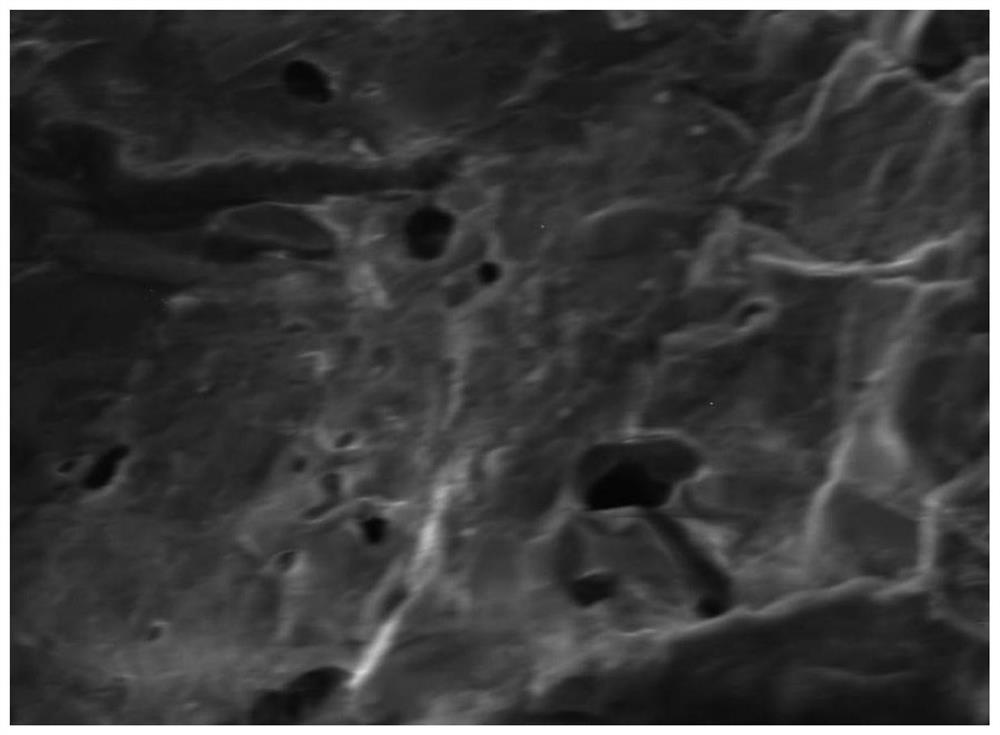

Image

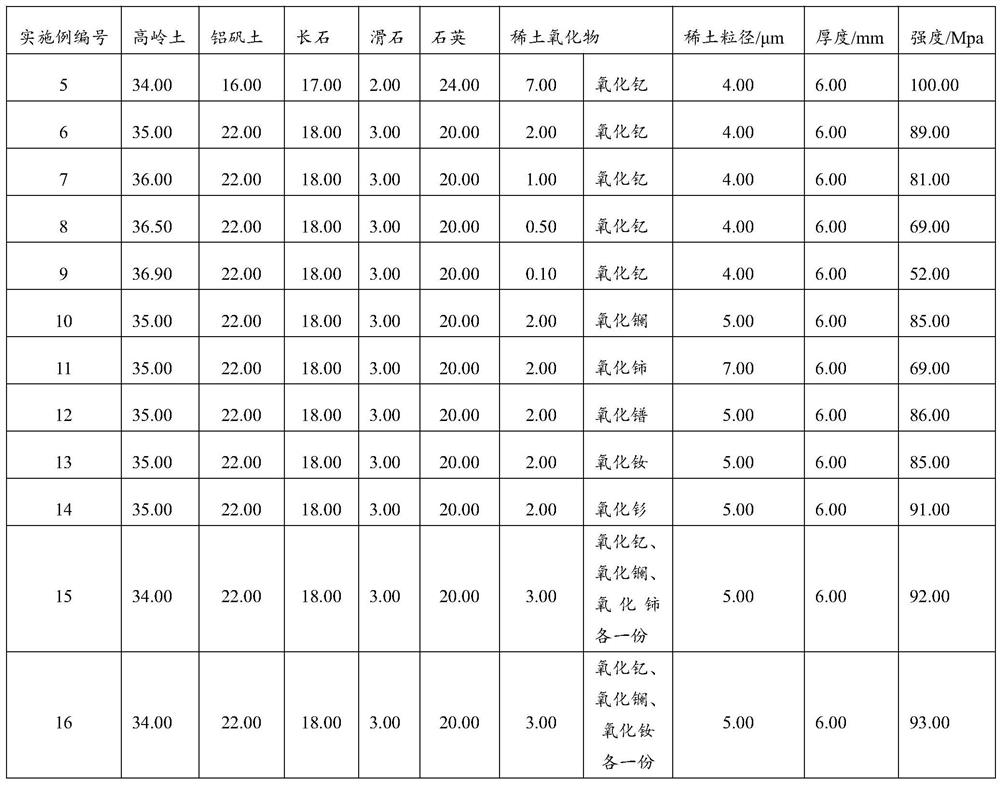

Examples

Embodiment 1

[0034] A rare earth oxide reinforced and toughened ceramic rock plate, comprising the following raw materials in parts by mass: 39 parts of kaolin, 19 parts of bauxite, 20 parts of feldspar, 2 parts of talc, 16 parts of quartz and 4 parts of yttrium oxide; The purity of yttrium is ≥99.5%, and the particle size is 6 μm. The preparation method of the slate is as follows:

[0035] S1: Add water to kaolin, bauxite, feldspar, talc, quartz and yttrium oxide mixture, ball mill and mix for 10 hours to prepare a mixed slurry with a solid content of 55%;

[0036] S2: The mixed slurry is spray-dried and granulated to obtain a spherical granular powder with certain fluidity and sieved to obtain a granular powder with a particle size distribution of 40%≤30 mesh≤80%, stale for 2 days , to obtain green powder with a moisture content of 7%;

[0037] S3: Pressing the obtained green body powder into a press to obtain a green body and drying;

[0038] S4: Treat the surface of the dried green b...

Embodiment 2

[0042] A rare earth oxide reinforced and toughened ceramic rock plate, comprising the following raw materials in parts by mass: 30 parts of kaolin, 35 parts of bauxite, 15 parts of feldspar, 18 parts of quartz, 1 part of yttrium oxide and 1 part of lanthanum oxide; The purity of yttrium oxide and lanthanum oxide is ≥99.0%, and the particle size is 1 μm. The preparation method of this slate is as follows:

[0043] S1: Add water to kaolin, bauxite, feldspar, talc, quartz, yttrium oxide and lanthanum oxide mixture, and ball mill and mix for 12 hours to prepare a mixed slurry with a solid content of 45%;

[0044] S2: The mixed slurry is spray-dried and granulated to obtain a spherical granular powder with certain fluidity and sieved to obtain a granular powder with a particle size distribution of 40%≤30 mesh≤80%, stale for 2 days , to obtain a green powder with a moisture content of 3%;

[0045] S3: Pressing the obtained green body powder into a press to obtain a green body and ...

Embodiment 3

[0049] A rare earth oxide reinforced and toughened ceramic rock plate, comprising the following raw materials in parts by mass: 45 parts of kaolin, 10 parts of bauxite, 25 parts of feldspar, 2.5 parts of talc, 17 parts of quartz, and 0.5 part of cerium oxide; The purity of cerium is ≥99.9%, and the particle size is 15 μm. The preparation method of this slate is as follows:

[0050] S1: Add water to kaolin, bauxite, feldspar, quartz, and cerium oxide mixture, and ball mill and mix for 5 hours to prepare a mixed slurry with a solid content of 65%;

[0051] S2: The mixed slurry is spray-dried and granulated to obtain a spherical granular powder with certain fluidity and sieved to obtain a granular powder with a particle size distribution of 40%≤30 mesh≤80%, stale for 2 days , to obtain green powder with a moisture content of 10%;

[0052] S3: Pressing the obtained green body powder into a press to obtain a green body and drying;

[0053] S4: Treat the surface of the dried gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com