Halogen-free flame-retardant insulating paint and preparation method thereof

A technology of insulating varnish and flame retardant, which is applied in coatings, fireproof coatings, polyester coatings, etc., and can solve the problems of high volatile content, high production cost, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

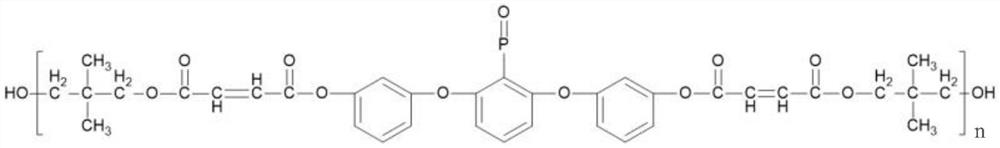

[0039] This example provides a kind of phosphorus-containing unsaturated polyester resin, and its preparation process is as follows:

[0040]Add 1.5 mol of resorcinol to 200 ml of xylene, heat up to 125°C to melt the resorcinol, start stirring, add 0.6 mol of phenylphosphoryl dichloride dropwise under stirring condition, and react at 125°C for 9 hours. Add 1.5mol maleic anhydride and 1mol neopentyl glycol at the end of the reaction, raise the temperature to 160°C, then gradually raise the temperature to 190°C at 10°C / h, keep warm until the acid value is less than or equal to 30mg KOH / g, distill under reduced pressure to obtain Phosphorus unsaturated polyester resin, light yellow solid with a number average molecular weight of 850.

Embodiment 2

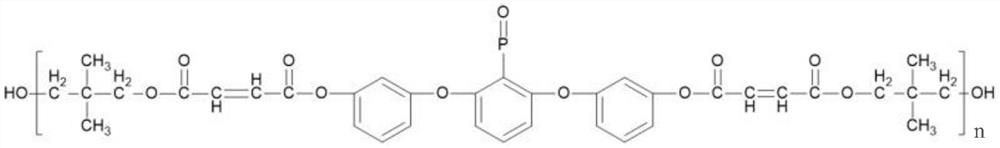

[0042] This example provides a kind of phosphorus-containing unsaturated polyester resin, and its preparation process is as follows:

[0043] Add 1.8 mol of resorcinol to 200 ml of xylene, heat up to 125°C to melt the resorcinol, start stirring, add 0.8 mol of phenylphosphoryl dichloride dropwise under stirring condition, and react at 125°C for 12 hours. Add 2mol maleic anhydride and 1.5mol neopentyl glycol at the end of the reaction, raise the temperature to 160°C, then gradually raise the temperature to 190°C at 10°C / h, keep warm until the acid value is ≤30mg KOH / g, and distill under reduced pressure to obtain Phosphorus unsaturated polyester resin, measured as a yellow solid with a number average molecular weight of 1000.

Embodiment 3

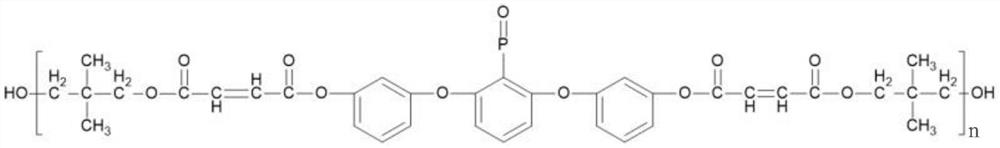

[0045] This example provides a kind of phosphorus-containing unsaturated polyester resin, and its preparation process is as follows:

[0046] Add 1.7mol resorcinol to 200ml xylene, heat up to 125°C to melt the resorcinol, start stirring, add 0.8mol phenylphosphoryl dichloride dropwise under stirring condition, and react at 125°C for 11 hours. Add 1.6mol maleic anhydride and 1.3mol neopentyl glycol at the end of the reaction, raise the temperature to 160°C, then gradually raise the temperature to 190°C at 10°C / h, keep warm until the acid value is less than or equal to 30mg KOH / g, and distill under reduced pressure to obtain Phosphorus-containing unsaturated polyester resin, light yellow solid with a number average molecular weight of 800.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com