Double-component anti-corrosion coating

An anti-corrosion coating, two-component technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of inconvenient construction of large objects in cold seasons, poor curing performance of epoxy resin paint, slow curing and other problems. Good UV resistance, good corrosion resistance, easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

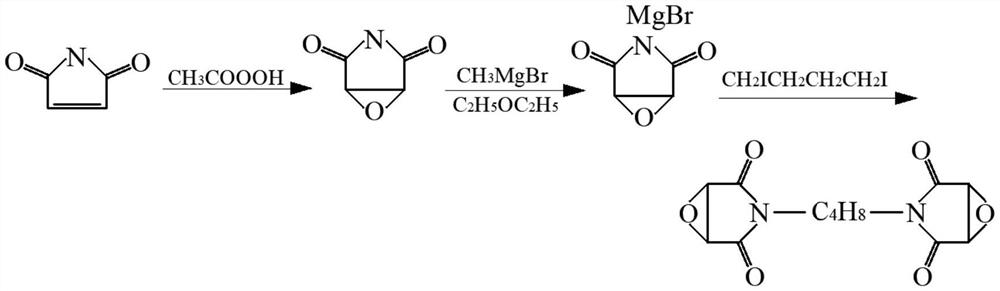

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of silicone-modified polyamide resin

[0026] (1) Prepare polyamide resin I according to the following steps:

[0027] Step 1: Add 54.42g glutaramide to 100.00g toluene, heat to 195°C for 15 minutes;

[0028] Step 2: Weigh 158.27g of polydimethylsiloxane (average DP is 100) and 2g of platinum (0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane;

[0029] Step 3: Add 5 g of polydimethylsiloxane dropwise to the reaction mixture;

[0030] Step 4: adding 0.8-1 g of platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane to the reaction mixture;

[0031] Step 5: adding the remaining polydimethylsiloxane dropwise to the reaction mixture;

[0032] Step 6: Add the remaining platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane to the reaction mixture, and continue the reaction for 1 hour, during which stirring is provided;

[0033] Step 7: Negative pressure distillation to remove the solvent to obtain polyamide resin I.

[0034] The general formula of polyam...

Embodiment 2

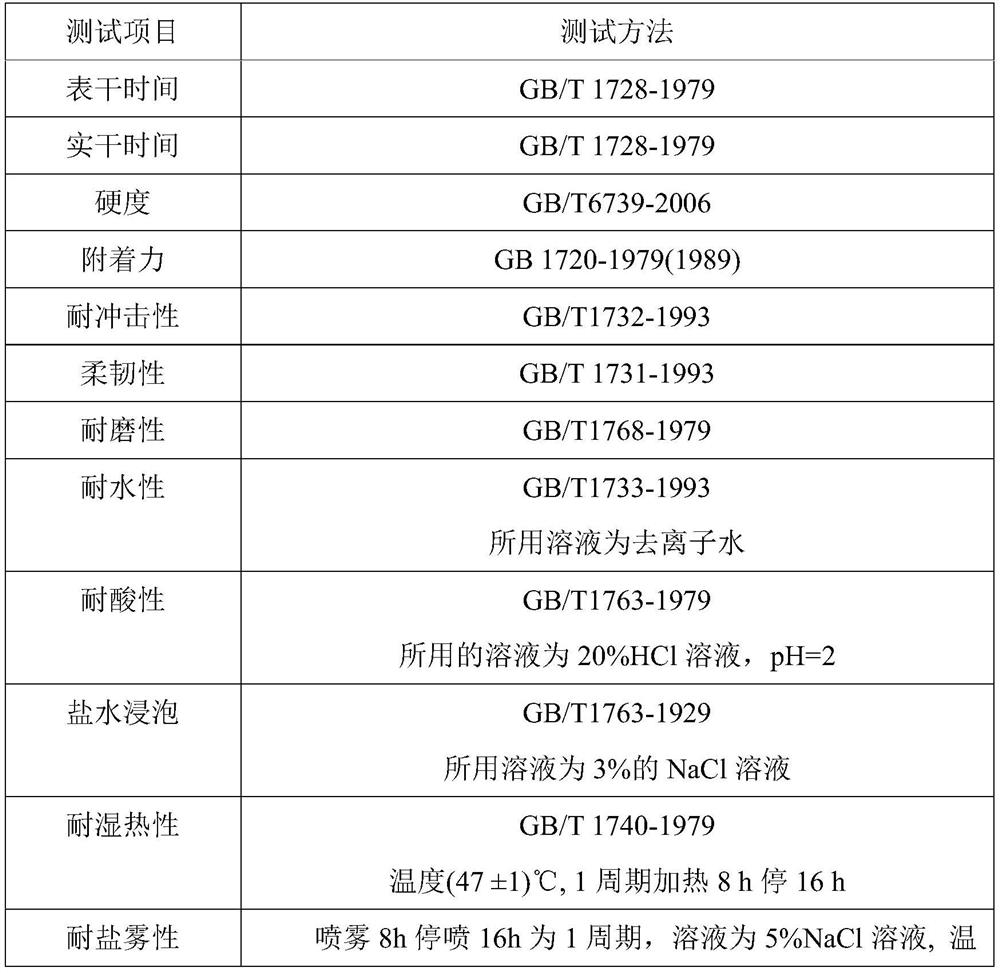

[0048] The two-component anti-corrosion coating provided in this embodiment includes component A and component B, wherein component B is a curing agent component, and this embodiment adopts 4 different materials as the components of the two-component anti-corrosion coating Divide B to set up 4 treatment groups. The specific setting method of each treatment group is: treatment IA, the polyamide resin I prepared in Example 1 is used as component B; treatment IIA, the polyamide resin II prepared in Example 1 is used as component B; treatment For IIIA, commercially available polyamide 651 is used as component B; for IVA, commercially available triethylenetetramine is used as component B. The formula composition of component A of each treatment group is exactly the same, and the raw materials used to prepare component A are shown in Table 2. According to Table 2, the required raw materials are fully mixed in proportion to obtain component A. In this embodiment The epoxy resin I pr...

Embodiment 3

[0055] The two-component anti-corrosion coating that this embodiment provides comprises component A and component B, and the raw material that this embodiment is used to prepare component A is as shown in Table 2, respectively adopts 2 kinds of different epoxy resins as in Table 2 The epoxy resin used to prepare component A is to set up two groups of treatment groups: process IB, use the epoxy resin I prepared in Example 1 as the epoxy resin used to prepare component A; process IIB, use commercially available Bisphenol A was used as the epoxy resin used to formulate Part A. According to Table 2, each treatment group mixed the required raw materials in proportion and fully mixed to obtain component A. Component B is the curing agent component, and the polyamide resin I prepared in Example 1 is used as the component B for each treatment group in this example. When using two-component anti-corrosion coatings of each treatment group, mix component A and component B according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com