A high-pressure directional solidification material and method thereof

A directional solidification, high pressure technology, applied in the field of non-equilibrium solidification, can solve the problems of uneven temperature distribution, inaccuracy, uneven temperature and pressure distribution, etc., to improve solid solubility, inhibit growth and refine grains, and increase shape. The effect of nuclear supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

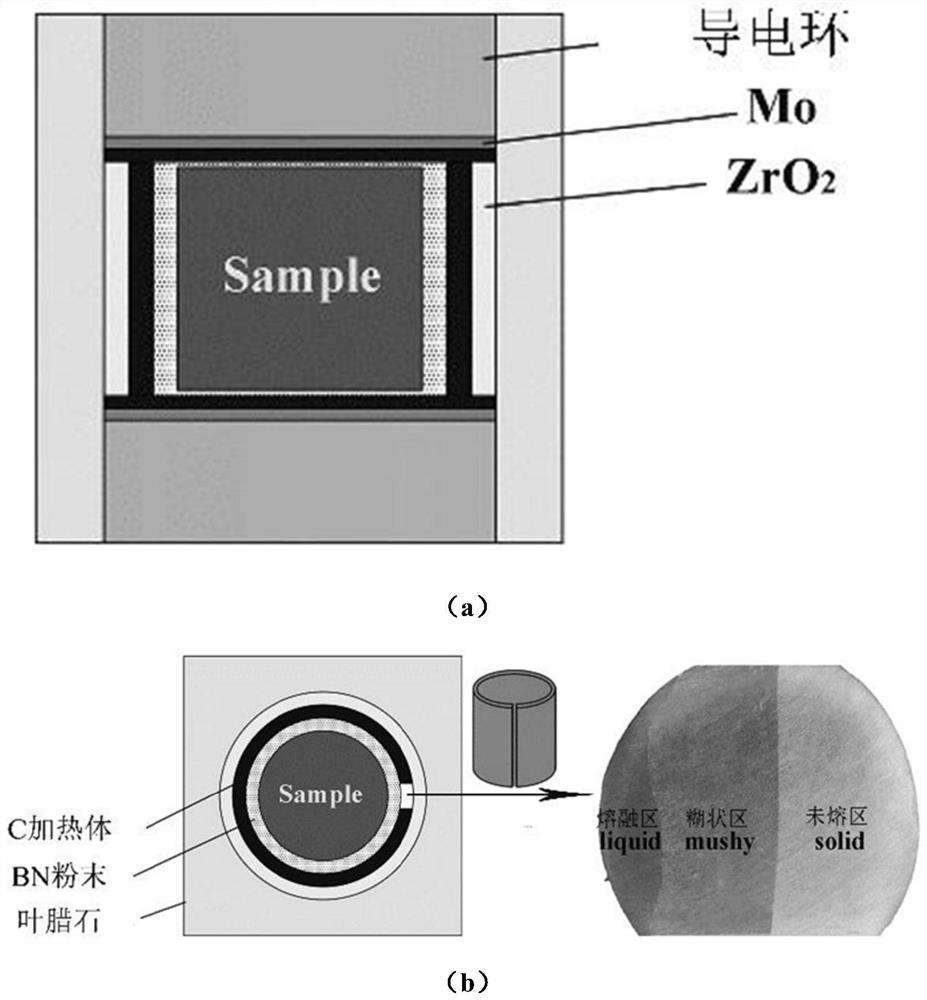

Method used

Image

Examples

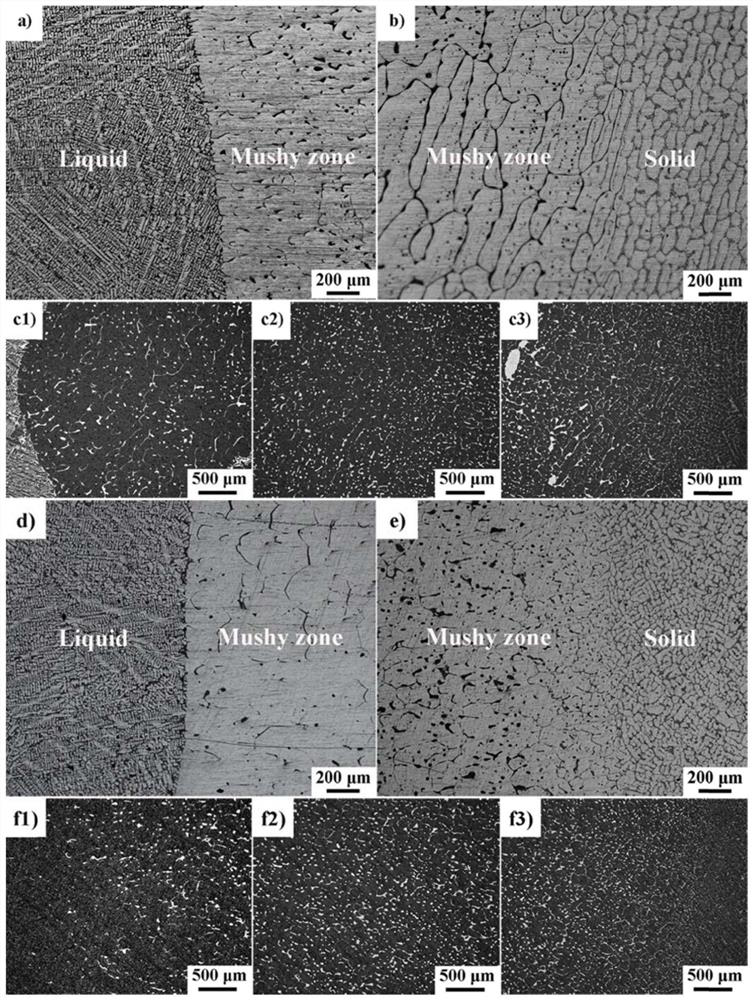

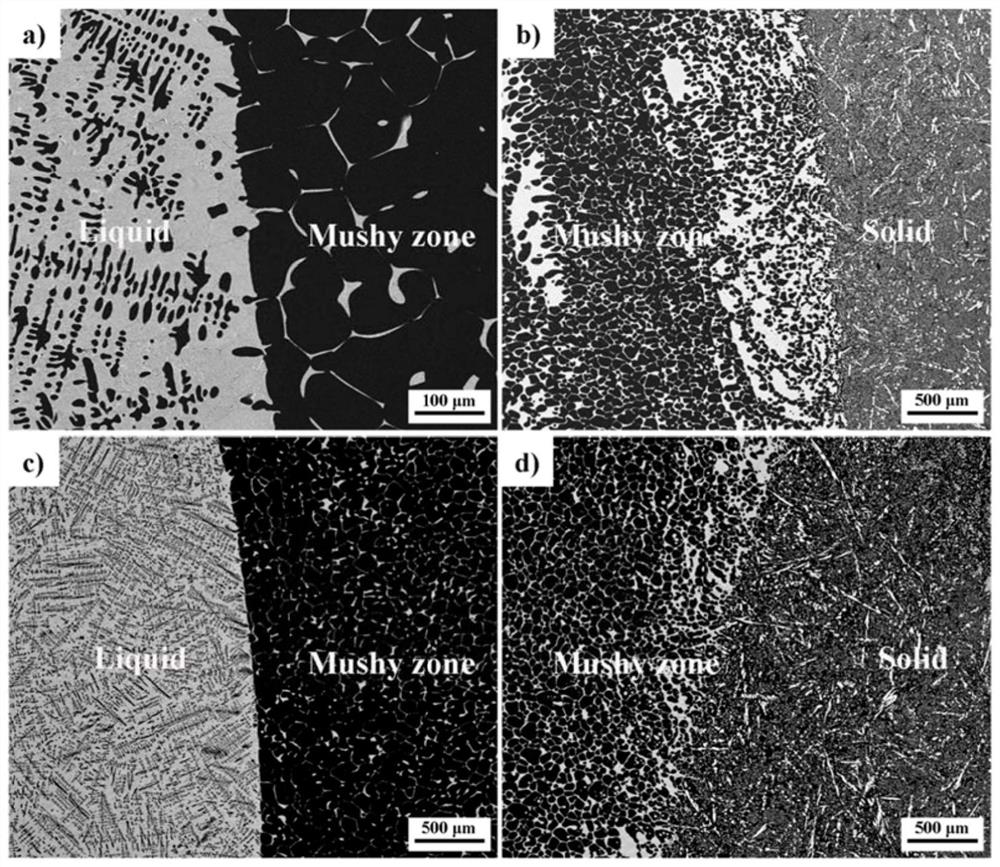

Embodiment 1

[0041] In this example, high-pressure directional solidification materials under different pressures were prepared. In this embodiment, the rated power of the resistance furnace is 7.5kW, a 20# graphite crucible is used, and the raw materials are 99.99wt.% Al and 99.99wt.% Ni. The specific method for preparing high-pressure directional solidification material is as follows:

[0042] (1) Weigh 1970g of Al block and 30g of Ni block, wash and dry them for later use.

[0043] (2) Preheat the 20# graphite crucible, put the Al block prepared in the step (1), and put the Ni block prepared in the step (1) after confirming that the Al block is completely melted.

[0044] (3) The mixture in step (2) is kept warm at 900°C until both are completely melted, and mixed evenly.

[0045] (4) After the temperature of the mixed melt in step (3) drops to around the melting point, pour it into a preheated cast iron mold, and take out the casting after cooling to room temperature.

[0046] (5) C...

Embodiment 2

[0054] In this example, high-pressure directional solidification materials under different pressures were prepared. In this embodiment, the rated power of the resistance furnace is 7.5kW, a 20# graphite crucible is used, and the raw materials are 99.99wt.% Al and 99.99wt.% Ni. The specific method for preparing high-pressure directional solidification material is as follows:

[0055] (1) Weigh 1823.2g of Al blocks and 176.8g of Ni blocks, wash and dry them for later use.

[0056] (2) Preheat the 20# graphite crucible, put the Al block prepared in the step (1), and put the Ni block prepared in the step (1) after confirming that the Al block is completely melted.

[0057] (3) The mixture in step (2) is kept warm at 1000°C until both are completely melted, and mixed evenly.

[0058] (4) After the temperature of the mixed melt in step (3) drops to around the melting point, pour it into a preheated cast iron mold, and take out the casting after cooling to room temperature.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com