Cyclohexane oxidation tail gas treatment method and device

A technology for oxidizing tail gas and treatment methods, which is applied in the direction of combustion methods, incinerators, lighting and heating equipment, etc. It can solve problems such as waste of energy resources, environment, exhaust volume and pressure of tail gas, and impact, and achieve less maintenance workload and high thermal efficiency. High, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

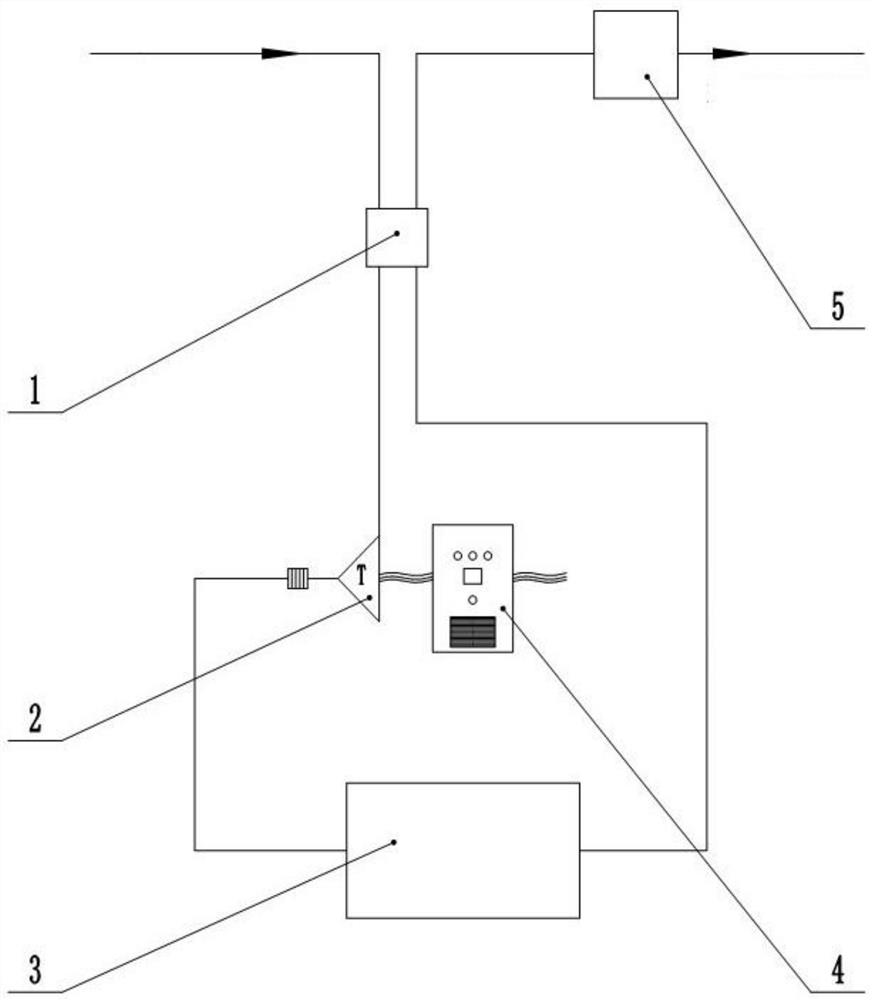

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] A method for treating cyclohexane oxidation tail gas, comprising the following steps:

[0027] (a) Heating the oxidation tail gas.

[0028] (b) Send the heated oxidized tail gas into the turbine generator set 2 to expand and generate electricity.

[0029] (b1) Incorporate the electricity generated by the turbine generator set 2 into the grid.

[0030] (c) Incinerating the expanded oxidized tail gas.

[0031] (c1) using the incinerated oxidation tail gas to heat the oxidation tail gas in step (a).

[0032] (d) discharging the incinerated oxidized tail gas into the atmosphere.

[0033] In the present invention, the oxidized tail gas discharged from the oxidation kettle is heated, expanded to generate electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com