Microcapsules containing natural oil and preparation method therefor

A technology of microcapsules and natural oils, applied in the direction of microcapsule preparation, microsphere preparation, biochemical equipment and methods, etc., can solve the problems of weak strength and achieve the effect of improving mechanical properties and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

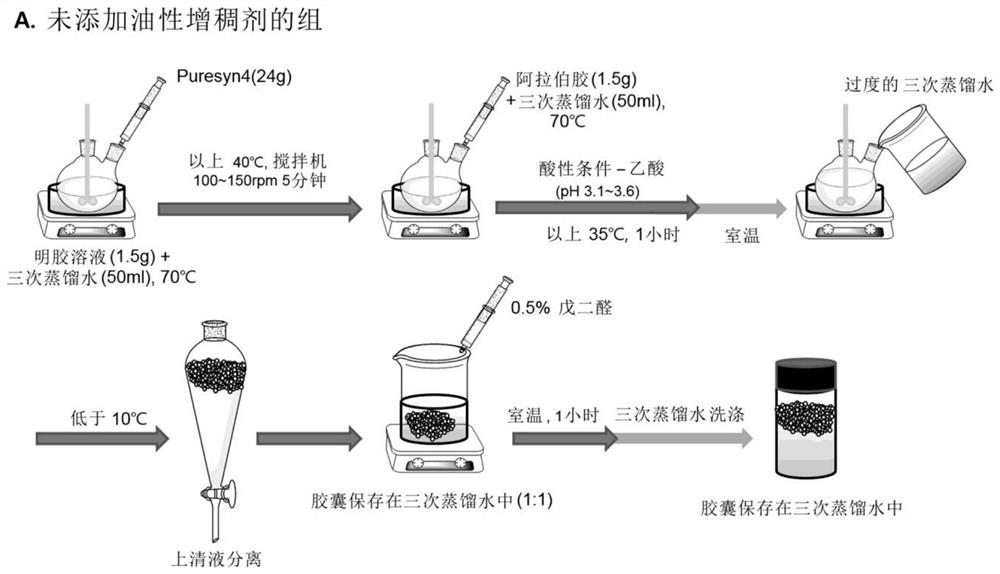

[0031] According to another embodiment of the present invention, the present invention provides a method for preparing microcapsules containing natural oil, comprising: step (a), preparing a gelatin solution containing gelatin, oil and an oily thickener; step (b), preparing natural oil polymer solution; step (c), mixing the above-mentioned gelatin solution and natural polymer solution; step (d), adjusting the pH of the mixture prepared in step (c); and step (e), cooling the conditioned pH mixture.

[0032] Specifically, the preparation method of the microcapsules of the present invention is shown in FIG. 1 .

[0033] Relative to the weight of the oil, 1% by weight to 15% by weight of the oily thickener of the above step (a) may be included, preferably, 2% by weight to 10% by weight of the oily thickener of the above step (a) may be included , more preferably, can contain 4% by weight to 6% by weight of the oily thickener of the above-mentioned step (a), most preferably, can c...

Embodiment 1

[0038] Embodiment 1. The preparation of gelatin oil capsule

[0039] 1-1. Experimental group 1

[0040] Microcapsules comprising gelatin, natural polymer and oil were prepared using the method shown in Figure 1 .

[0041]Specifically, the gelatin solution was prepared by mixing 1.5 g of gelatin (pig, 300 bloom, type A) and 50 ml of triple distilled water, and then heating the mixture to 70° C. to completely dissolve the gelatin. The natural polymer solution was prepared by mixing 1.5 g of gum arabic and 50 ml of triple distilled water, and keeping the mixture at a temperature of 70° C. to completely dissolve the gum arabic. After adding 24 g of squalane (hydrogenated poly1-decen, puresyn4) as oil to the above gelatin solution, it was stirred at a temperature of 40° C. or higher by a stirrer at a rotation speed of 100 rpm to 150 rpm for 5 minutes. After adding the above-mentioned natural polymer solution to the stirred gelatin solution, the pH is adjusted to 3.1 to 3.6 using ...

Embodiment 2

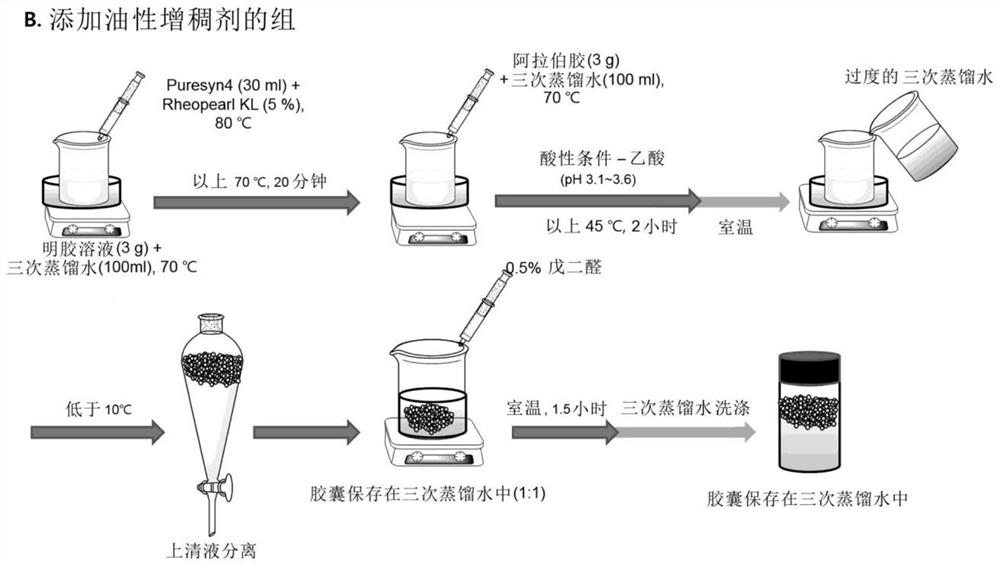

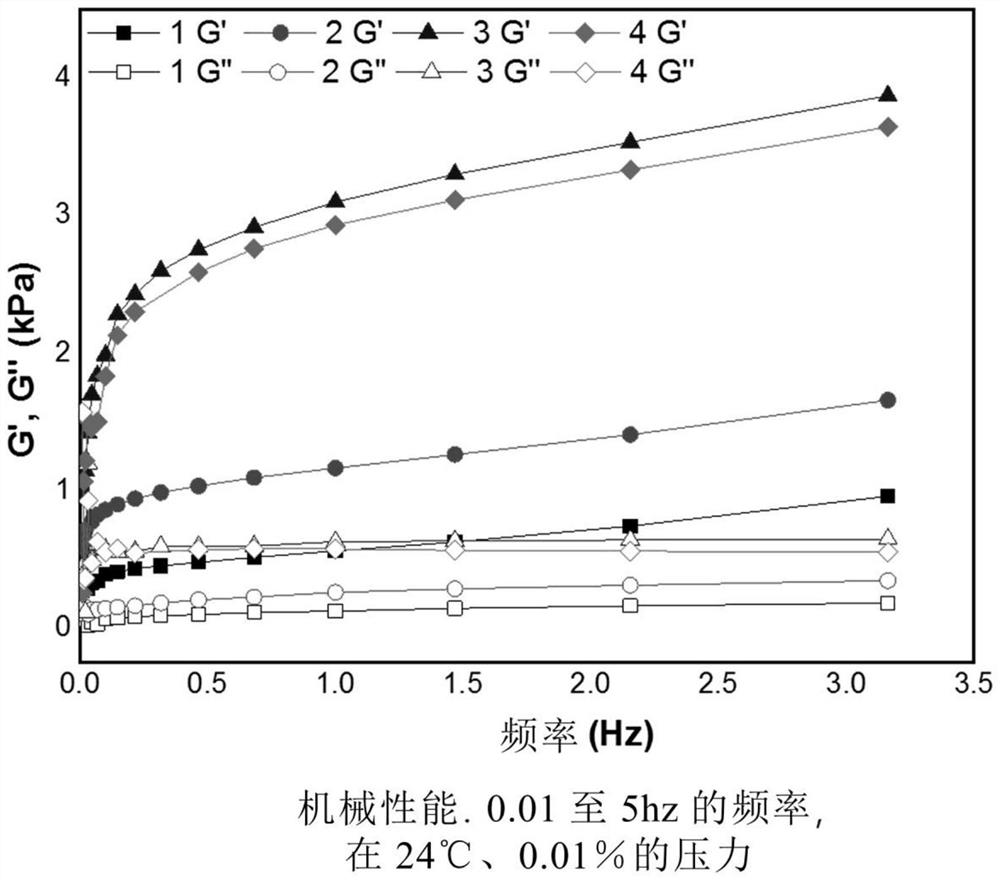

[0051] Embodiment 2. The coefficient of elasticity detection of gelatin oil capsule

[0052] The elastic modulus of the gelatin oil capsules of experimental group 1 to experimental group 4 was detected. Specifically, gelatin oil capsules were arranged between two flat plates with a distance of 1000 μm and a radius of 20 mm. The coefficient of elasticity was analyzed using a rotating rheometer (TA Instruments, AR 1500ex type) at room temperature with the pressure (strain) fixed at 0.01, and analyzed within the range of 0.01 to 5 Hz. The detection result of elastic coefficient of gelatin oil capsule is as follows: figure 2 shown.

[0053] Such as figure 2 As shown, in the preparation of gelatin oil capsules, when a part of the gum arabic was replaced with hyaluronic acid, it was confirmed that the elasticity of the gelatin oil capsules increased. In particular, it was confirmed that the elasticity of the experimental group 3 mixed with gum arabic and hyaluronic acid at a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com