Device for removing trace aromatic hydrocarbons in disproportionated and transalkylation tail hydrogen through recontact and removal method for same

A technology of transalkylation and recontact, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as the loss of aromatic hydrocarbons that cannot be reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the embodiments of the accompanying drawings.

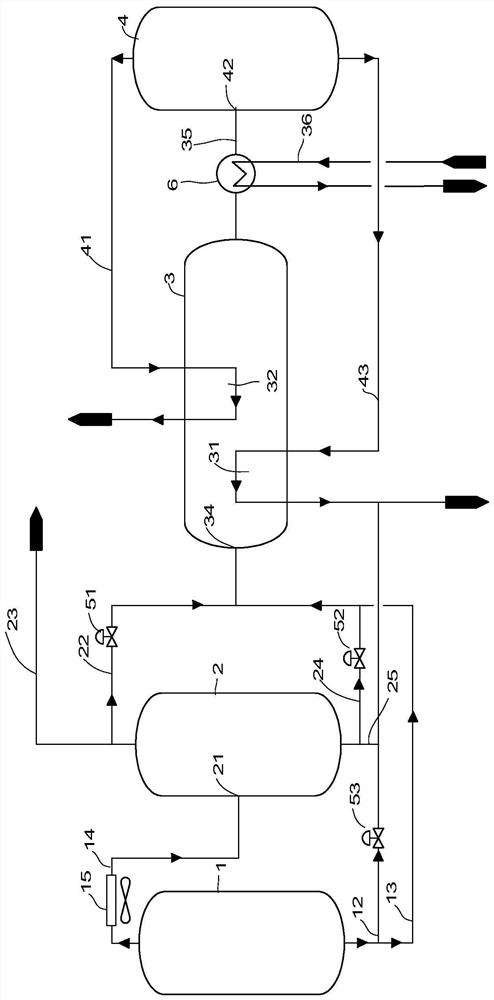

[0032] Such as figure 1 As shown, the device for re-contacting dedisproportionation and alkylation of trace aromatics in tail hydrogen in this embodiment includes a hot separation tank 1, a cold separation tank 2, a heat exchanger 3, a tail gas cooler 6, an oil-gas separation tank 4, Chilled water pipe 36 and mixed oil and gas pipe 35.

[0033] The top end of the heat separation tank 1 has a first gas phase delivery pipe 14 , and the bottom end has a first bottom liquid output pipe 12 and a second bottom liquid output pipe 13 .

[0034] The top of the cold separation tank 2 has a second gas phase delivery pipe 22 and a hydrogen circulation pipe 23, the middle part has a first feed inlet 21, and the bottom has a third bottom liquid outlet pipe 24 and a fourth bottom liquid outlet pipe 25; the first feed inlet 21 is connected with the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com