Device for preparing carbon quantum dots and using method thereof

A carbon quantum dot and syringe pump technology, applied in the field of nano-functional material preparation, can solve problems such as affecting product quality, increasing production cost, and easily blocking microtubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

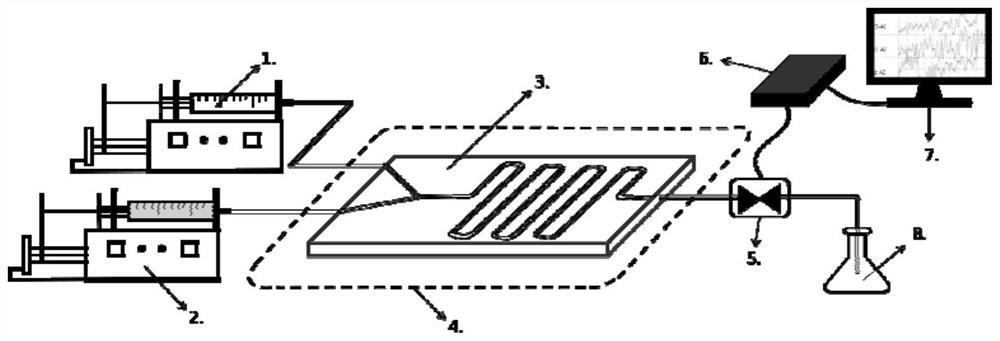

[0051] A method utilizing said device to prepare carbon quantum dots, said method comprising the steps of:

[0052] (1) The chip microreactor 3 is connected with the heating jacket 4, heated to 120°C, and the reaction pressure is set on the computer to be 0.1MPa, and the pressure in the chip microreactor 3 is controlled by the pressure sensor 6 and the back pressure valve 5 ;

[0053] (2) Two syringes are used to draw freshly squeezed orange juice and deionized water respectively as reactants, and are respectively installed on the first syringe pump 1 and the second syringe pump 2, and the flow rate is set on the syringe pumps, and the freshly squeezed orange juice and deionized water The flow rate ratio of water is 1:19, and two streams of reactants are passed into the chip microreactor 3 and reacted for 10min. After the reaction is completed, the back pressure valve 5 is opened, and the reaction product flows into the collector 8;

[0054] (3) After filtering the reaction p...

Embodiment 2

[0057] A method utilizing said device to prepare carbon quantum dots, said method comprising the steps of:

[0058] (1) The chip microreactor 3 is connected to the heating jacket 4, heated to 120°C, and the reaction pressure is set on the computer as 2MPa, and the pressure in the chip microreactor 3 is controlled by the pressure sensor 6 and the back pressure valve 5;

[0059] (2) Two syringes are used to draw freshly squeezed orange juice and deionized water respectively as reactants, and are respectively installed on the first syringe pump 1 and the second syringe pump 2, and the flow rate is set on the syringe pumps, and the freshly squeezed orange juice and deionized water The flow rate ratio of water is 1:19, and two streams of reactants are passed into the chip microreactor 3 and reacted for 10min. After the reaction is completed, the back pressure valve 5 is opened, and the reaction product flows into the collector 8;

[0060] (3) After filtering the reaction product ob...

Embodiment 3

[0063] A method utilizing said device to prepare carbon quantum dots, said method comprising the steps of:

[0064] (1) The chip microreactor 3 is connected to the heating jacket 4, heated to 120°C, and the reaction pressure is set on the computer as 4MPa, and the pressure in the chip microreactor 3 is controlled by the pressure sensor 6 and the back pressure valve 5;

[0065] (2) Two syringes are used to draw freshly squeezed orange juice and deionized water respectively as reactants, and are respectively installed on the first syringe pump 1 and the second syringe pump 2, and the flow rate is set on the syringe pumps, and the freshly squeezed orange juice and deionized water The flow rate ratio of water is 1:19, and two streams of reactants are passed into the chip microreactor 3 and reacted for 20min. After the reaction is completed, the back pressure valve 5 is opened, and the reaction product flows into the collector 8;

[0066] (3) After filtering the reaction product ob...

PUM

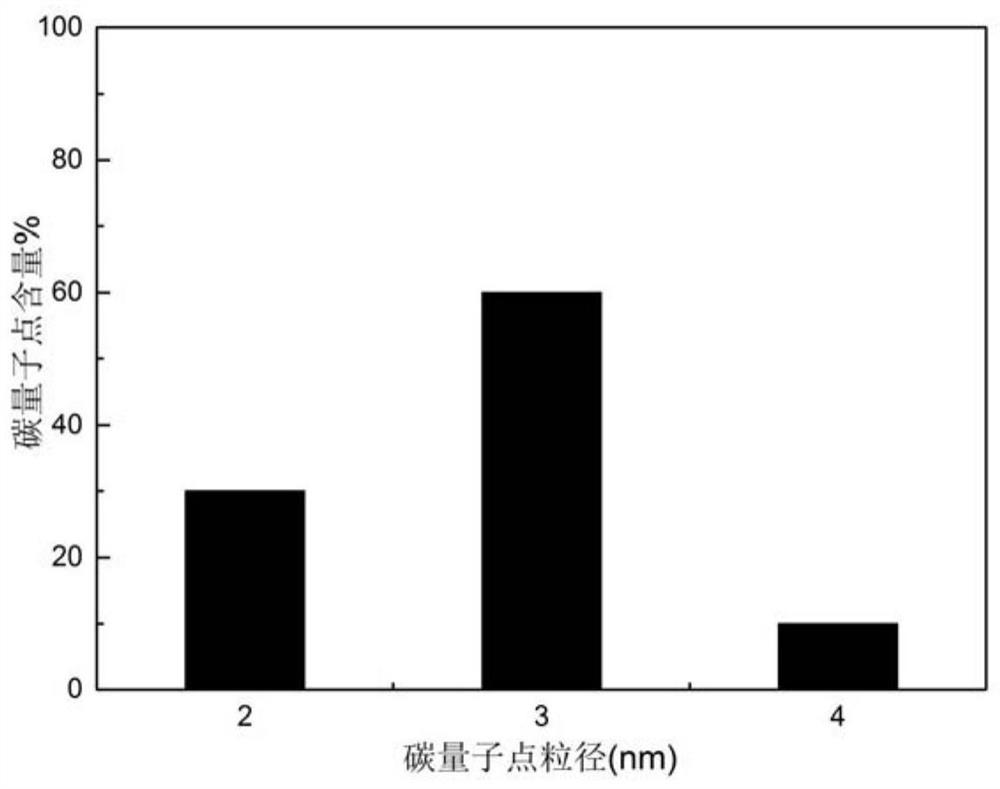

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com