Method for preparing carbon quantum dots from milk

A technology of carbon quantum dots and milk, which is applied in the field of preparation of carbon quantum dots, can solve the problems of high energy consumption, long time consumption, and low efficiency, and achieve the effects of simple operation, high heat and mass transfer rate, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

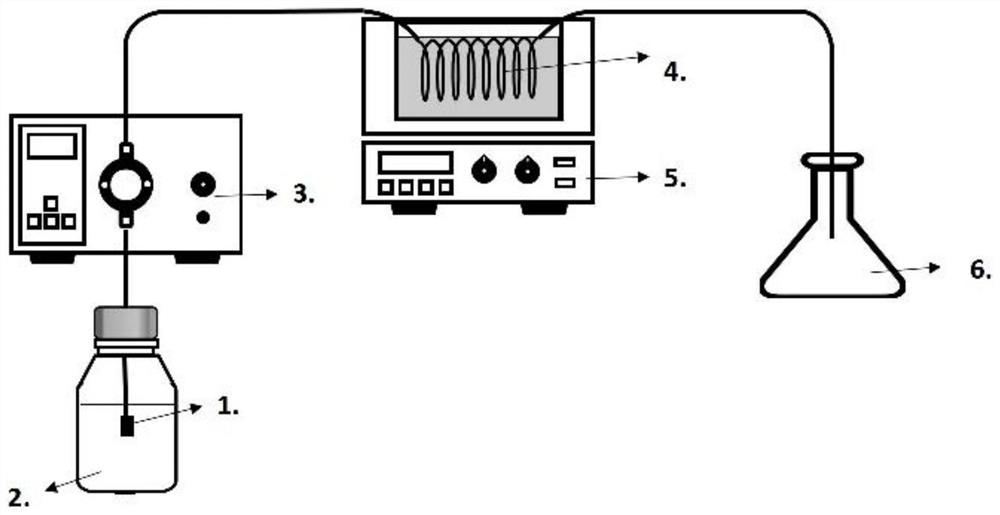

[0033] (1) Connect the reaction device as required, place the pipeline reactor in an oil bath and heat it to 120 degrees.

[0034] (2) A 1:19 mixture of fresh milk and deionized water was passed into the pipeline reactor by using a convection pump, stayed under heating conditions for 30 min, and the reaction product was collected by an Erlenmeyer flask.

[0035] (3) After filtering with a 0.22 μm nano filter head, the product was dialyzed in distilled water for 12 hours with a 1000 Da dialysis bag, and dried to obtain carbon quantum dot powder.

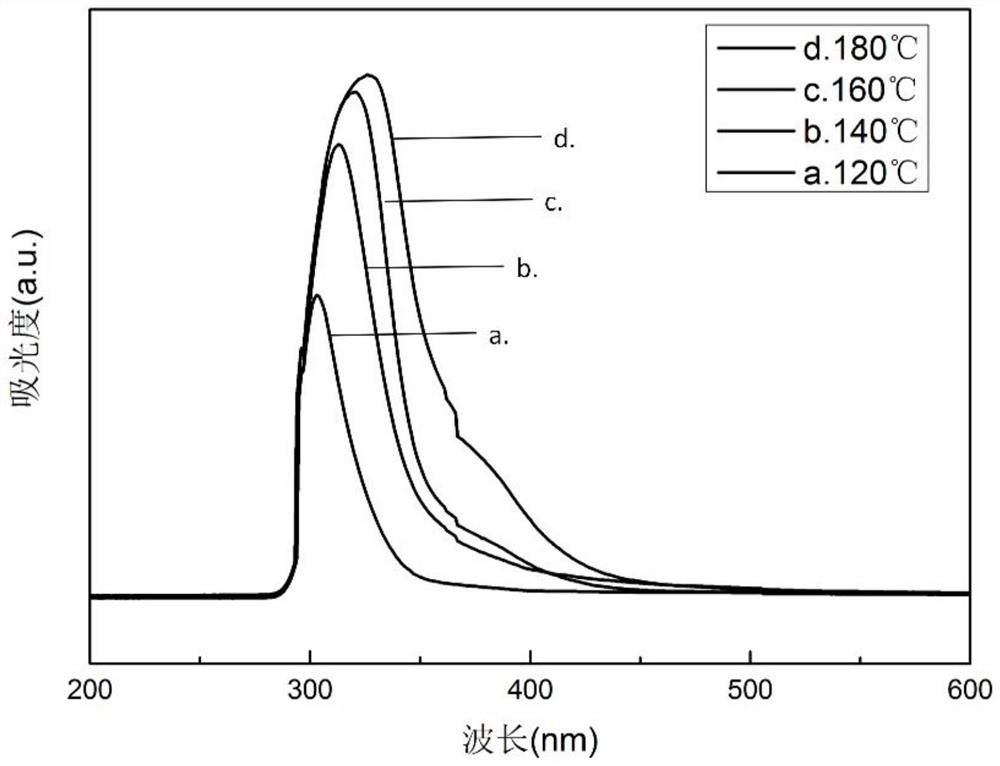

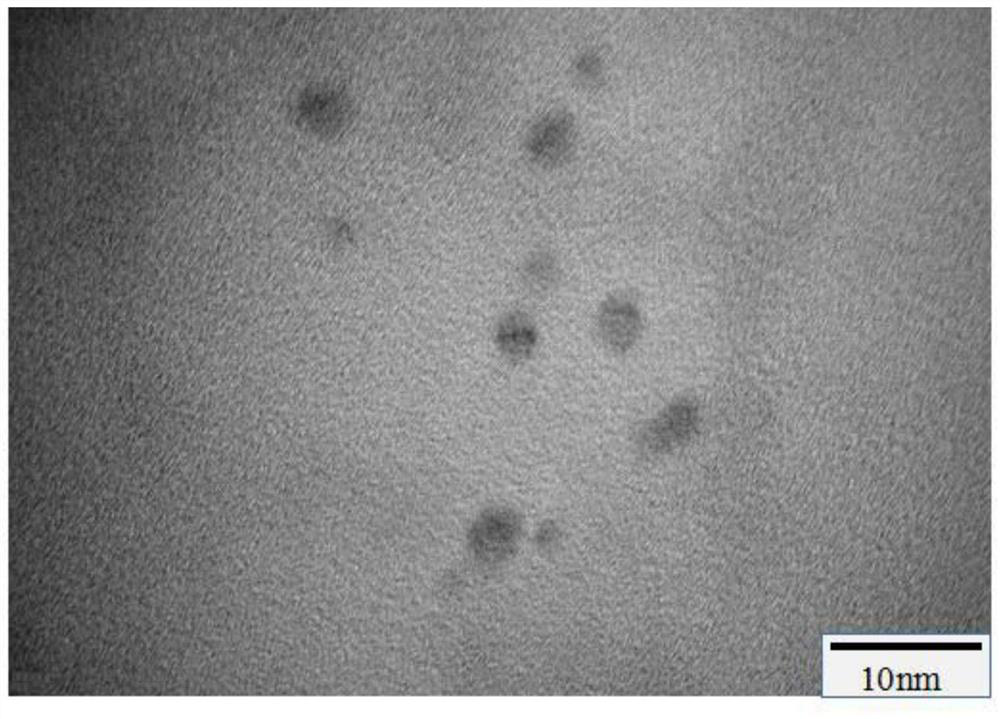

[0036] Take a small amount of product and measure the UV-Vis spectrum, the result is as follows figure 2 Shown in curve a. In addition, a small amount of the product was dispersed in ethanol for ultrasonic treatment to prepare a TEM sample, and the above solution was subjected to transmission electron microscope detection, and the results were as follows: image 3 Shown in a. It can be seen that carbon quantum dots with good unifo...

Embodiment 2

[0038] The treatment process and treatment time are the same as in Example 1, except that the reaction temperature is 140 degrees. Take a small amount of product and measure the UV-Vis spectrum, the result is as follows figure 2 As shown in the middle curve b, it can be seen that the absorption peak shifts slightly to the right and the absorption intensity increases.

Embodiment 3

[0040] The treatment process and treatment time are the same as in Example 1, except that the reaction temperature is 160 degrees. Take a small amount of product and measure the UV-Vis spectrum, the result is as follows figure 2 As shown in the middle curve c, it can be seen that the absorption peak continues to shift to the right and the absorption intensity continues to increase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com