A system and method for continuously synthesizing mononitrotoluene in an ultrasonic microreactor

A technology of mononitrotoluene and micro-reactor, which is applied in the field of ultrasonic application and micro-chemical technology, can solve the problems of difficult control of reaction temperature, long reaction time, low safety of mononitrotoluene, etc., and achieve free disassembly and replacement , high heat and mass transfer rate, easy to integrate and scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

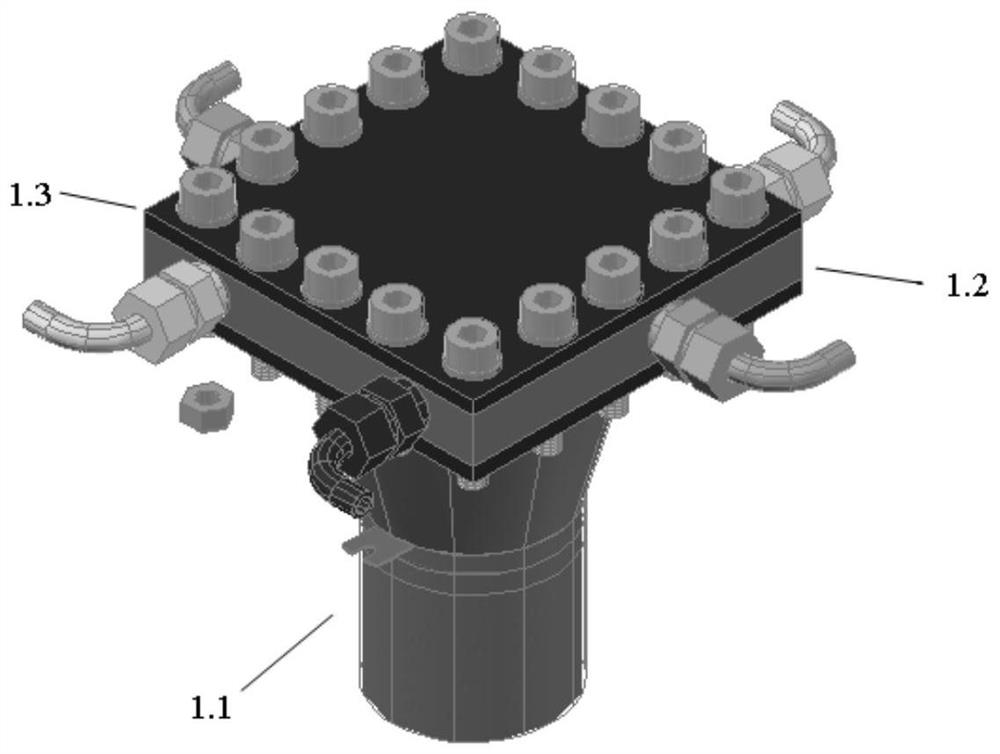

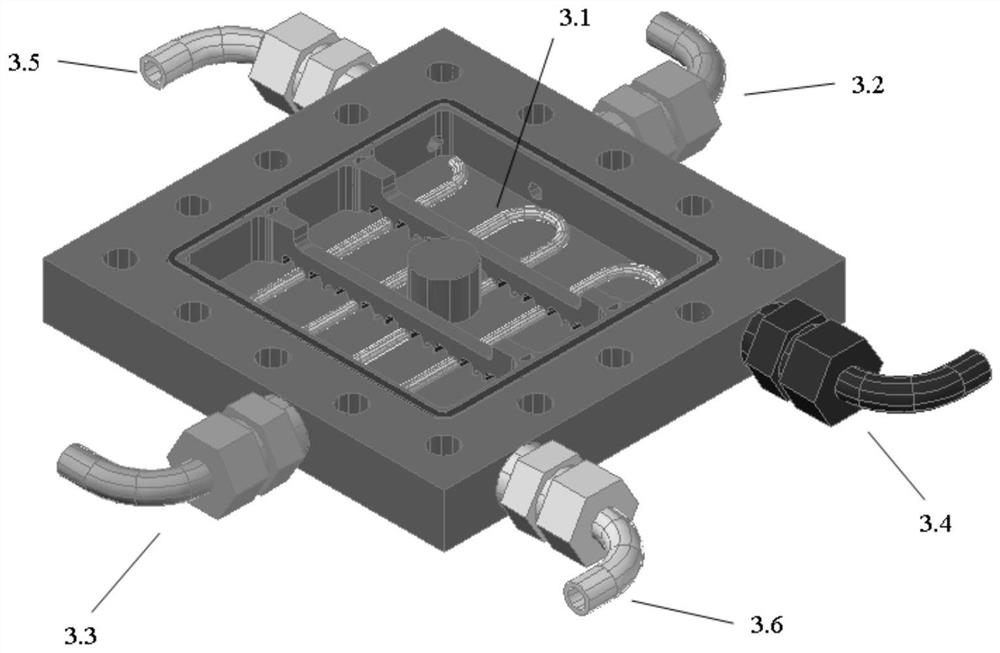

[0044] In this embodiment, a modular temperature-controlled ultrasonic microreactor with a resonant frequency of 20 kilohertz is used as an example. figure 1 , 3 It can be seen that the ultrasonic microreactor in this embodiment is composed of a sandwich ultrasonic transducer 1.1, a temperature control chamber 1.2, a packaging cover plate 1.3 and a capillary microreactor 3.1.

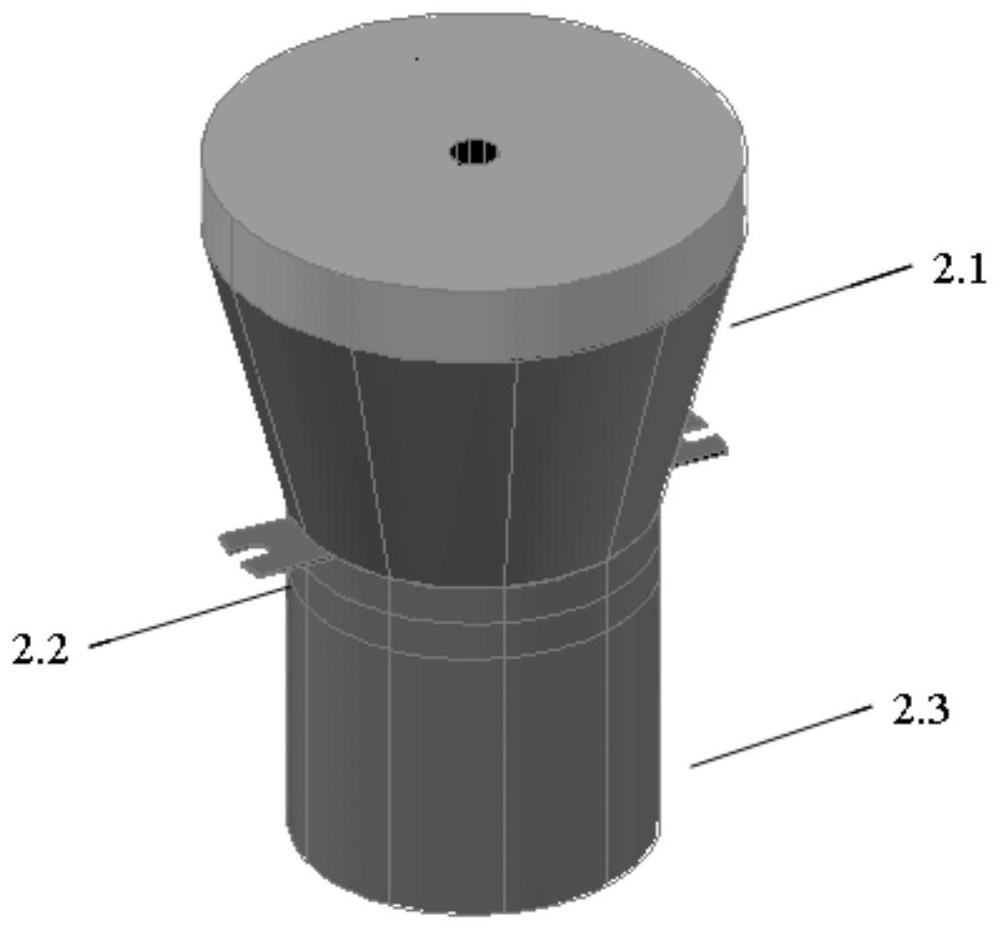

[0045] The capillary microreactor 3.1 of this embodiment is made of 316 stainless steel, with an outer diameter of 1.6 mm and an inner diameter of 0.6 mm. The sandwich ultrasonic transducer 1.1 has an operating frequency of 20 kHz and a maximum input power of 100W. It consists of a front cover 2.1, a piezoelectric ceramic stack 2.2 and a rear cover 2.3 connected at the center by high-strength metal bolts. The piezoelectric ceramic stack 2.2 is composed of two piezoelectric ceramic sheets stacked coaxially to form a cylinder with a thickness of 10mm. Each piezoelectric ceramic sheet has a thickness of 5...

Embodiment 2

[0047] In this embodiment, a temperature-controlled ultrasonic microreactor with a resonant frequency of 40 kilohertz is used as an example. figure 1 , 3 It can be seen that the ultrasonic microreactor in this embodiment is composed of a sandwich ultrasonic transducer 1.1, a temperature control chamber 1.2, a packaging cover plate 1.3 and a microreactor 3.1.

[0048] The microreactor 3.1 of this embodiment is made of PTFE, with an outer diameter of 2.0 mm and an inner diameter of 1.0 mm. The sandwich ultrasonic transducer 1.1 has an operating frequency of 40 kHz and a maximum input power of 60 W. It consists of a front cover 2.1, a piezoelectric ceramic stack 2.2 and a rear cover 2.3 connected at the center by high-strength metal bolts. The piezoelectric ceramic stack 2.2 is composed of two piezoelectric ceramic sheets coaxially stacked into a cylinder with a thickness of 10mm. The thickness of each piezoelectric ceramic sheet is 5mm and the diameter is 38mm. The piezoelectri...

Embodiment 3

[0050] The temperature-controlled ultrasonic microreactor is the same as example 1, with pure toluene as raw material 1, nitric acid mixed acid as nitrating agent 2 (water 10%, sulfuric acid 68%, nitric acid 22%, mass fraction), utilizes advection pump 3,4 to transport two strands Feed to micromixer and capillary microreactor. The flow rate of toluene is 0.2 ml / min, the flow rate of nitrating agent is 0.3 ml / min, and the ratio of feed material of nitrating agent to toluene is 1.05. The microreactor (with an inner diameter of 0.6 mm) is made of stainless steel, immersed in the ultrasonic radiation area, and the temperature is controlled at 45° C. using a water bath. The ultrasonic radiation frequency is 20KHz, the power is 50W, and the material residence time is 13.2s. The product is collected into the sample collection tank at the outlet, left to stand for phase separation, and the upper organic phase is taken and washed three times with saturated sodium bicarbonate solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com