Method for capturing CO2 in hydrophobic microchannel

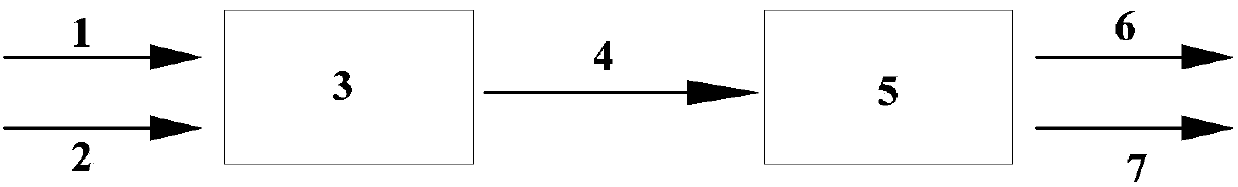

A micro-channel, hydrophobic technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of insufficient mobility and large volume of absorption towers, and achieves favorable gas-liquid dispersion, heat and mass transfer. The effect of high speed and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The absorbent and the mixed gas are simultaneously fed into the non-hydrophobic modified microchannel reactor to complete the CO 2 Absorption. The mass ratio of each component in the absorbent is sulfolane: diisopropanolamine: water is 2:2:1, and the mixed gas used is composed of CO 2 and N 2 Composed of CO 2 and N 2 The mole fractions are 50%, diisopropanolamine and CO 2 The molar ratio is 2.2, the volume flow rate of the mixed gas is 500Nml / min, the operating pressure is 5MPa, the operating temperature is 45°C, the hydraulic radius of the microchannel used is 500 microns, the contact angle with water is 60°, CO 2 After absorption, the absorption rate can reach 93%, among which, the system pressure drop is 1.5atm, and the gas-liquid contact area is 5500m 2 / m 3 .

Embodiment 2

[0025] The absorbent and the mixed gas are simultaneously fed into the non-hydrophobic modified microchannel reactor to complete the CO 2 Absorption. The mass ratio of each component in the absorbent is sulfolane: diisopropanolamine: water is 2:2:1, and the mixed gas used is composed of CO 2 and CH 4 Composed of CO 2 and CH 4 The mole fractions are 50%, diisopropanolamine and CO 2 The molar ratio of the gas mixture is 2.2, the volume flow rate of the mixed gas is 350Nml / min, the operating pressure is 5MPa, the operating temperature is 45°C, the hydraulic radius of the microchannel used is 500 microns, the contact angle with water is 60°, CO 2 After absorption, the absorption rate can reach 95%, among which, the system pressure drop is 1.2atm, and the gas-liquid contact area is 4000m 2 / m 3 .

Embodiment 3

[0027] The absorbent and the mixed gas are simultaneously fed into the non-hydrophobic modified microchannel reactor to complete the CO 2 Absorption. The mass ratio of each component in the absorbent is sulfolane: N-methyldiethanolamine: piperazine: water is 2:1.6:0.4:1, and the mixed gas used is composed of CO 2 and N 2 Composed of CO 2 The mole fraction of is 10%, and the rest is N 2 , N-methylglycolamine and CO 2 The molar ratio is 5.0, the volume flow rate of the mixed gas is 150Nml / min, the operating pressure is 3MPa, the operating temperature is 30°C, the hydraulic radius of the microchannel used is 400 microns, the contact angle with water is 70°, CO 2 After absorption, the absorption rate can reach 87%, among which, the system pressure drop is 0.7atm, and the gas-liquid contact area is 3500m 2 / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com