Application of rhodium monatomic catalyst in reaction for preparing m-chloroaniline through selective hydrogenation of m-chloronitrobenzene

A chloronitrobenzene and catalyst technology, which is applied in the preparation of amino compounds, the preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems such as catalyst stability enhancement and dechlorination, and achieve superior catalytic activity, dechlorination side effects. Effects of reduced reaction and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

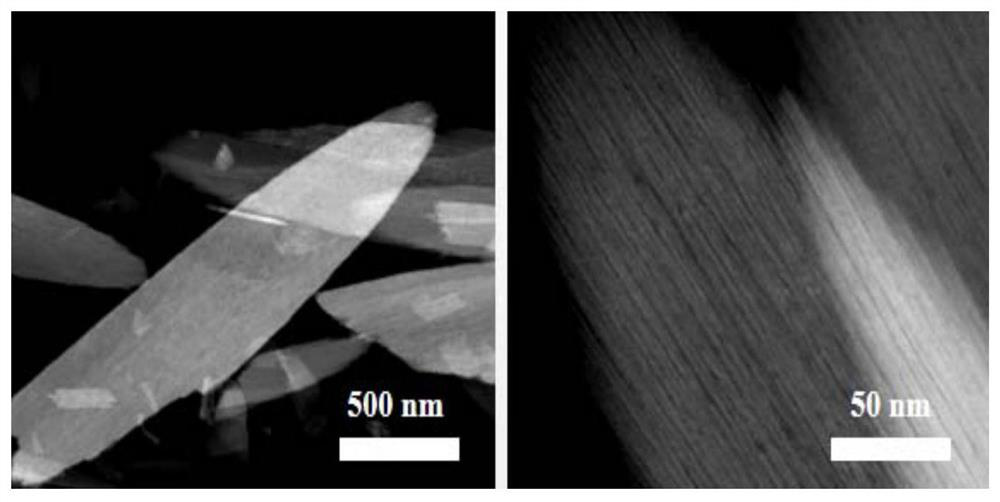

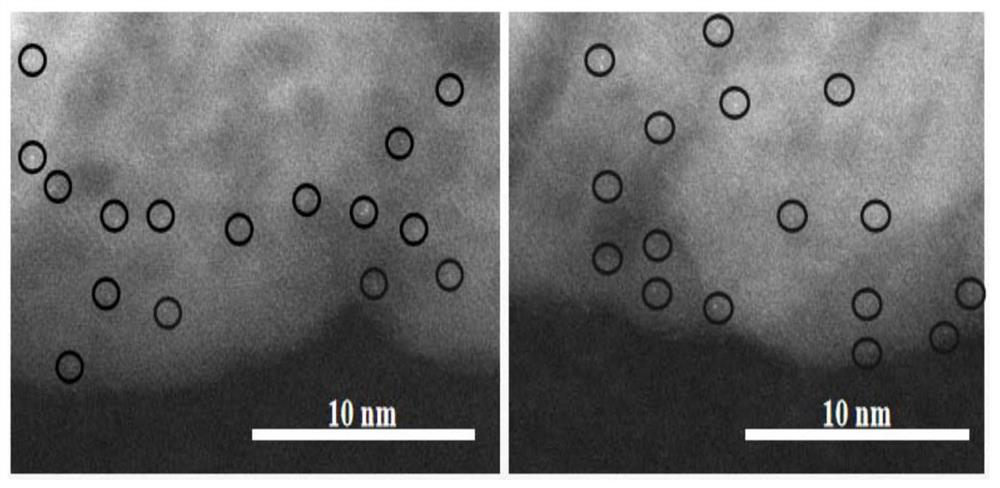

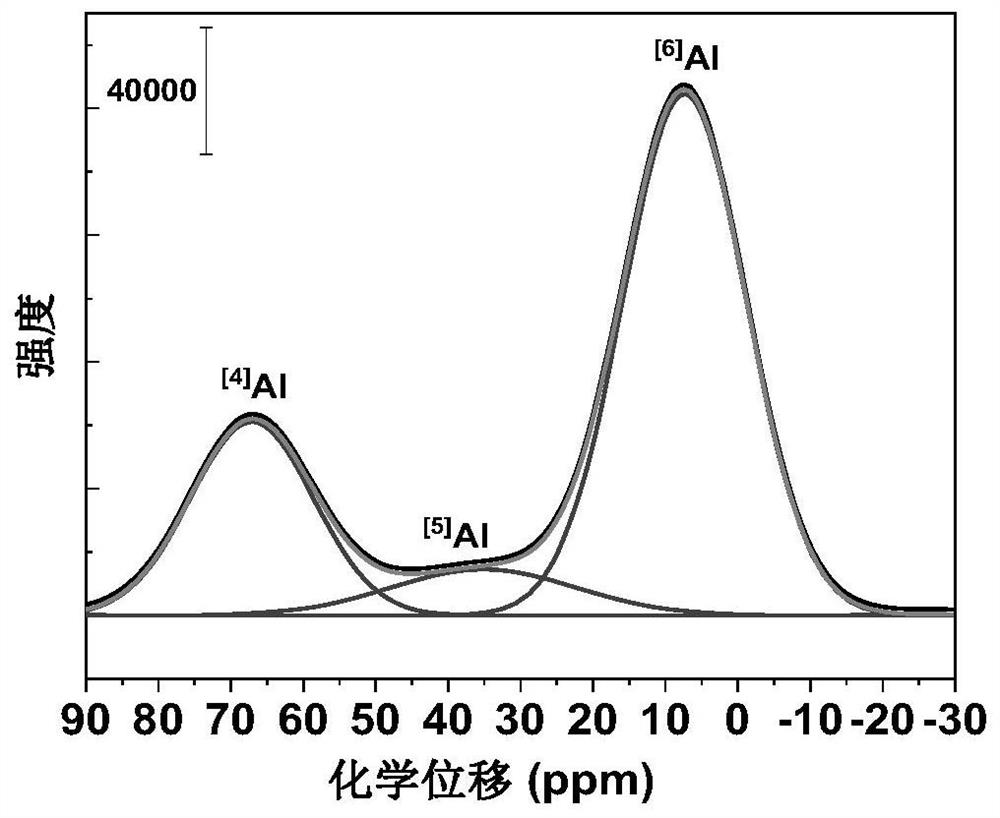

[0032] Single atom 0.1wt% Rh-Al 2 o 3 Preparation of -C catalyst

[0033] Weigh 5.2g of aluminum nitrate nonahydrate and dissolve it in 20mL of water, and add 1.152g of terephthalic acid to it, add 0.8mL of RhCl 3 solution (10mg Rh / mL), ultrasonicated for 10min, transferred to a 50mL hydrothermal reactor, placed in a temperature-programmed oven, set the heating rate at 1°C / min, heated at 220°C for 72h, and then slowly lowered to room temperature , filter, H 2 O. Wash with ethanol three times, and then put the sample into a 60°C oven to dry to obtain the Rh-MIL-53(Al) material. After grinding, the Rh-MIL-53(Al) sample was transferred into a tube furnace, raised to a pyrolysis temperature of 600 °C at a heating rate of 5 °C / min, and pyrolyzed for 5 h in a nitrogen atmosphere. After natural cooling, it was obtained Rh-Al 2 o 3 -C precursor. Subsequently, the dried precursor was transferred into a tube furnace under 10% H 2 / Ar atmosphere at 300 ℃ for reduction, the heatin...

Embodiment 2

[0044] The monoatomic 0.1wt% Rh-Al prepared in the above example 1 2 o 3 -C catalyst is used to catalyze the selective hydrogenation of m-chloronitrobenzene to prepare m-chloroaniline reaction. First, take 78.78mg m-chloronitrobenzene, 30mg catalyst and 2mL toluene in a 10mL autoclave at room temperature, and feed N 2 Replace 3 times, then pass H 2 Replace 3 times, let H 2 The pressure is 2Mpa. Put the reaction kettle into the water bath, turn on the stirring, and start the reaction when the temperature of the water bath rises to 40°C. After reacting for 3 hours, cool down, take an appropriate amount of the reaction solution and centrifuge it for gas chromatography analysis.

Embodiment 3

[0046] Catalytic reaction performance comparison

[0047] The 0.1wt%Rh-Al prepared in Example 1 of the present invention 2 o 3 -C, 0.1wt% Rh / γ-Al prepared in Comparative Example 1 2 o 3 Compared with the reaction performance of the 0.1wt%Rh / C catalyst prepared in Comparative Example 2 to catalyze the selective hydrogenation of m-chloronitrobenzene to prepare m-chloroaniline, see Table 1. Reaction condition is with embodiment 4.

[0048] Catalytic reaction performance comparison of different catalysts in table 1

[0049]

[0050] As can be seen from Table 1 ("-" means not detected), the monoatomic 0.1wt% Rh-Al prepared in Example 1 of the present invention 2 o 3 The -C catalyst has the highest reactivity and selectivity to m-chloroaniline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com