Continuous post-treatment process for octabromoether

A technology for post-treatment of octabromoether, which is applied in the field of continuous post-treatment of octabromoether, can solve the problems of unstable quality of the end product octabromoether, inability to effectively reduce, high content of octabromoether ions, etc. time, prevention of product instability, and high washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

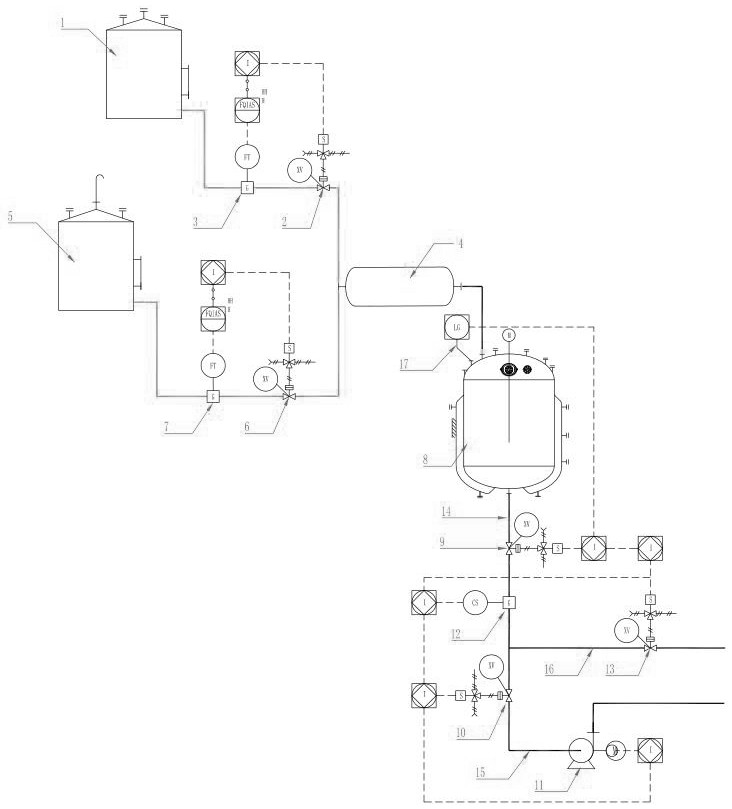

[0047] A continuous post-treatment process for octabromoether, wherein:

[0048] The discharge port of the octabromoether storage tank 1 is connected with the feed port of the dynamic tubular reactor 4 through a pipeline, and a flow meter 3 and an automatic control valve 2 are arranged in sequence according to the flow direction of the material.

[0049] The flow meter 3 is connected with the flow remote transmitter, and the flow remote transmitter is connected with the flow accumulation indication alarm interlock, and the flow accumulation indication alarm interlock is connected with the controller. At the same time, the controller is connected with the solenoid valve, and the solenoid valve is used to adjust the air source AS and drive the actuator to operate to open or cut off the self-control valve 2 .

[0050] The discharge port of the water storage tank 5 is connected with the feed port of the dynamic tubular reactor 4 through a pipeline, and a flow meter 7 and an automa...

Embodiment 2

[0072] A continuous post-treatment process for octabromoether, wherein:

[0073] The discharge port of the octabromoether storage tank 1 is connected with the feed port of the dynamic tubular reactor 4 through a pipeline, and a flow meter 3 and an automatic control valve 2 are arranged in sequence according to the flow direction of the material.

[0074] The flow meter 3 is connected with the flow remote transmitter, and the flow remote transmitter is connected with the flow accumulation indication alarm interlock, and the flow accumulation indication alarm interlock is connected with the controller. At the same time, the controller is connected with the solenoid valve, and the solenoid valve is used to adjust the air source AS and drive the actuator to operate to open or cut off the self-control valve 2 .

[0075] The discharge port of the water storage tank 5 is connected with the feed port of the dynamic tubular reactor 4 through a pipeline, and a flow meter 7 and an automa...

Embodiment 3

[0097] A continuous post-treatment process for octabromoether, wherein:

[0098] The discharge port of the octabromoether storage tank 1 is connected with the feed port of the dynamic tubular reactor 4 through a pipeline, and a flow meter 3 and an automatic control valve 2 are arranged in sequence according to the flow direction of the material.

[0099] The flow meter 3 is connected with the flow remote transmitter, and the flow remote transmitter is connected with the flow accumulation indication alarm interlock, and the flow accumulation indication alarm interlock is connected with the controller. At the same time, the controller is connected with the solenoid valve, and the solenoid valve is used to adjust the air source AS and drive the actuator to operate to open or cut off the self-control valve 2 .

[0100] The discharge port of the water storage tank 5 is connected with the feed port of the dynamic tubular reactor 4 through a pipeline, and a flow meter 7 and an automa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com