Stone-like coating and preparation method thereof

A technology of real stone paint and emulsion, applied in the field of coatings, can solve the problem that it is difficult to balance the hardness and environmental protection of real stone paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides a kind of preparation method of above-mentioned genuine stone paint, comprises the following steps:

[0066] The emulsion, natural sand and calcium lime powder are mixed.

[0067] Preferably, for the real stone paint containing emulsion, natural sand, filler, lime lime powder, water, dispersant, wetting agent, defoamer, film-forming aid, pH regulator and preservative in the formula, its preparation method comprises Follow the steps below;

[0068] (1) Pre-mixing: Mix part of water, dispersant, wetting agent, defoamer, film-forming aid and pH regulator, stir, disperse for 1-5 minutes, add emulsion and stir, and prepare the mixture after stirring a.

[0069] (2) Dispersion: In the state of stirring, add filler to mixture A, stir for 15-20 minutes, add natural sand, continue stirring to obtain mixture B.

[0070] (3) Viscosity adjustment: under stirring state, add preservative and remaining water into mixture B, stir and mix to prepar...

Embodiment 1

[0076] This embodiment provides a genuine stone paint and a preparation method thereof.

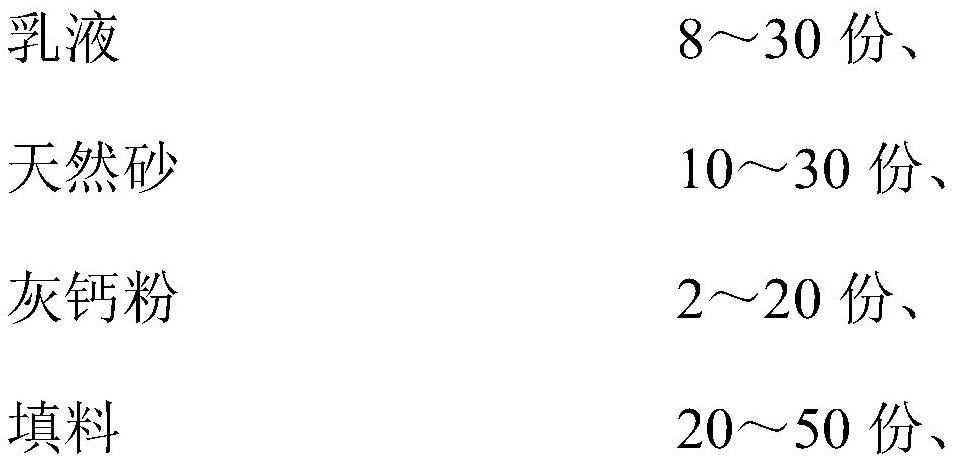

[0077] (1) In parts by weight, the raw materials for the preparation of real stone paint 1 are as follows:

[0078]

[0079]

[0080] Among them, the EZ3010 emulsion is a VAE emulsion, and the glass transition temperature of the polymer is about 6°C.

[0081] (2) Preparation of real stone paint 1:

[0082] ①Pre-mixing: Disperse 90% of water, dispersant, wetting agent, 50% of defoamer, film-forming aid, and pH regulator for 1-5 minutes, then add emulsion and stir, and then prepare mixture A .

[0083] ② Dispersion: Add titanium dioxide and heavy calcium to mixture A under stirring, add natural sand after stirring for 15-20 minutes, and continue stirring to obtain mixture B.

[0084] ③ Viscosity adjustment: Add preservative, remaining water and remaining defoamer to the stirring mixture B, and stir evenly to obtain real stone paint 1.

Embodiment 2

[0086] This embodiment provides a genuine stone paint and a preparation method thereof.

[0087] (1) In parts by weight, the raw materials for the preparation of real stone paint 2 are as follows:

[0088]

[0089]

[0090] Among them, the EZ3010 emulsion is a VAE emulsion, and the glass transition temperature of the polymer is about 6°C.

[0091] (2) Preparation of real stone paint 2:

[0092] The preparation method is the same as in Example 1, and real stone paint 2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com