Method for preparing bio-mechanical primary color pulp from wheat straw and fully utilizing byproducts

A technology for mechanical pulp and by-products, which is applied in the recovery of pulp by-products, pulp beating/refining methods, and pulping with inorganic alkalis, etc., can solve the problem of by-products, which has not been well solved, and is not conducive to the comprehensive high-value utilization of agricultural straws. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

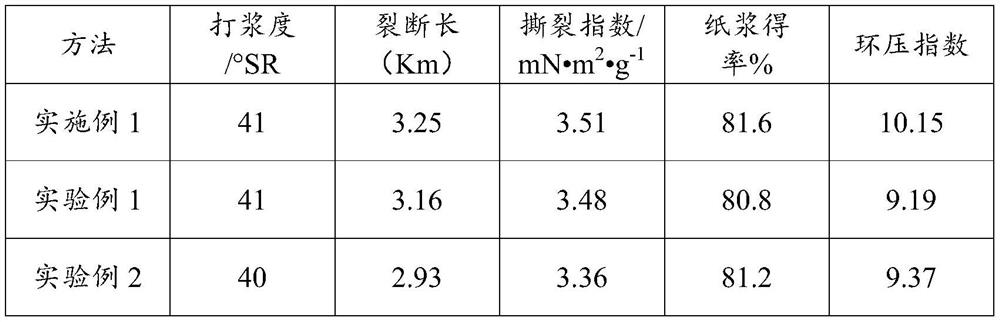

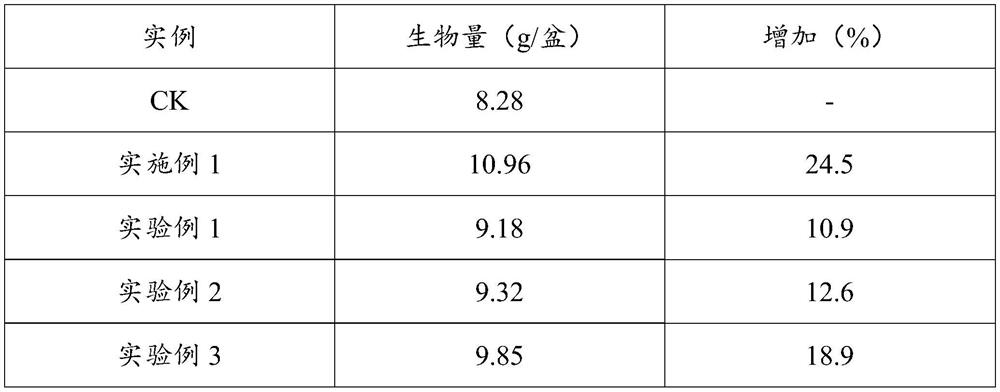

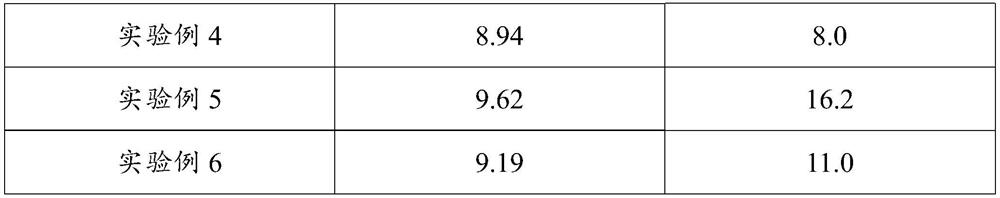

Examples

Embodiment 1

[0048] Example 1 A method for preparing biomechanical primary color paste and by-products from wheat straw straw

[0049] Described method comprises the following steps:

[0050] (1) Cut the wheat straw after physical selection and dedusting into small pieces of 2 cm, put it into the reaction kettle of the normal temperature processor, and carry out hot water treatment on the wheat straw according to the liquid ratio of 1:4, the temperature is 100 ℃, and the treatment time is 30 minutes ; At the same time, the rotten wheat straw that cannot be processed and used is collected;

[0051] (2) Add 2.5% KOH to the mixture of hot water and wheat straw in the reactor or processor, adjust the pH value of the hot water to 14, process for 30 minutes, and the temperature is 100°C to dissolve a small part of the hemifiber in the wheat straw Substances such as element, lignin and pectin, while the wheat straw is saturated and softened by water heat, the pH value of the water content of the...

Embodiment 2

[0056] Example 2 A method for preparing biomechanical primary color paste and by-products from wheat straw straw

[0057] Described method comprises the following steps:

[0058] (1) Cut the wheat straw after physical selection and dedusting into small pieces of 3 cm, put it into a processor or a reaction kettle, and carry out hot water mixing treatment on the wheat straw according to the liquid ratio of 1:5, the temperature is 110°C, and the processing time is 40 minutes; At the same time, the rotten wheat straw that cannot be used for processing is collected;

[0059] (2) Add 2% KOH to the hot water and wheat straw mixture in the reactor or processor, adjust the pH value of the hot water to 13, the temperature is 95°C, and the treatment time is 30 minutes; a small part of the hemifiber is dissolved in the wheat straw Substances such as element, lignin and pectin, while the wheat straw is saturated and softened by water heat, the pH value of the water content of the wheat st...

Embodiment 3

[0064] Example 3 A method for preparing biomechanical primary color paste and by-products from wheat straw straw

[0065] (1) Cut the wheat straw after physical selection and dedusting into small pieces of 2cm, put it into a processor or a reaction kettle, and treat the wheat straw with hot water according to the liquid ratio of 1:4, the temperature is 95°C, and the treatment time is 60min ; At the same time, the rotten wheat straw that cannot be processed and used is collected;

[0066] (2) Add 1.5% KOH to the mixture of hot water and wheat straw in the reactor or processor, adjust the pH value of the hot water to 13, process for 30 minutes, and the temperature is 100°C to dissolve a small part of the hemifiber in the wheat straw Substances such as element, lignin and pectin, while the wheat straw is saturated and softened by water heat, the pH value of the water content of the wheat straw reaches 8 at the end of the treatment, and the lye wastewater is collected;

[0067] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com