Silicon-based negative electrode material and preparation method thereof, negative electrode, battery and electronic device

A silicon-based anode material, silicon-based technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems affecting the performance of silicon-based anode materials, crushing silicon-based anode materials, and restricting the application of silicon-based anode materials. , to achieve the effect of improving cycle performance and stability, high film layer stability, and stable long-term performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

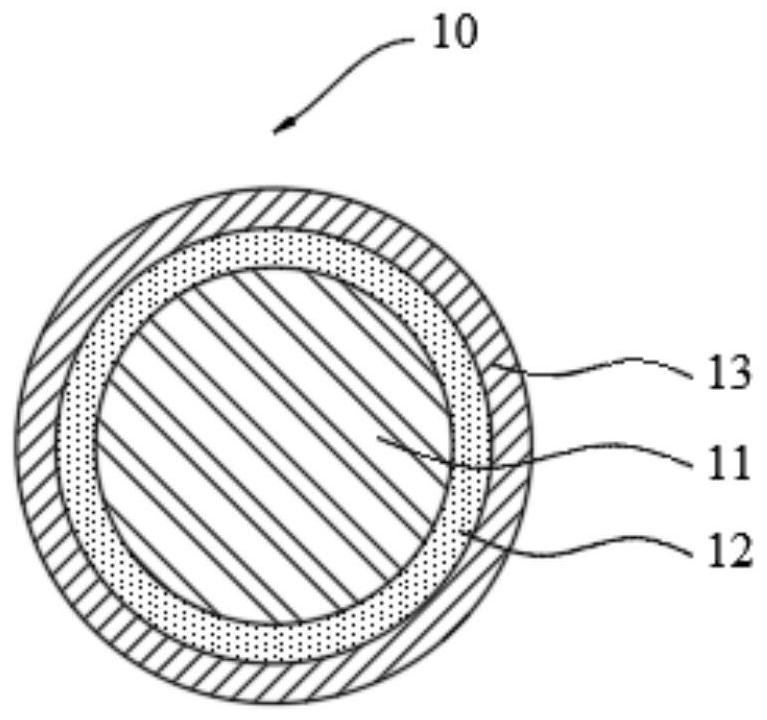

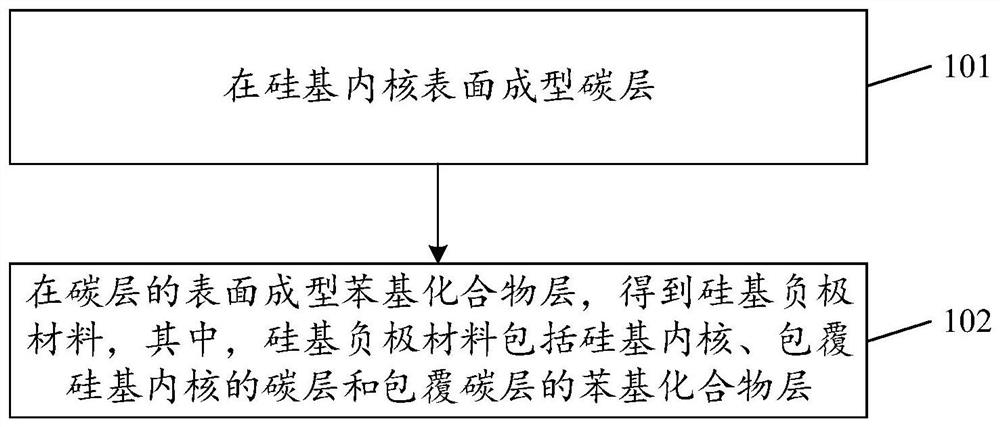

[0054] The present application also provides a method for preparing the silicon-based negative electrode material 10 , the preparation method prepares the silicon-based negative electrode material 10 in any one of the above-mentioned embodiments. see figure 2 , is a schematic flow diagram of a method for preparing a silicon-based negative electrode material provided in an embodiment of the present application, including:

[0055] Operation 101: forming a carbon layer on the surface of the silicon-based core.

[0056] Operation 102: forming a phenyl compound layer on the surface of the carbon layer to obtain a silicon-based negative electrode material, wherein the silicon-based negative electrode material includes a silicon-based core, a carbon layer covering the silicon-based core, and a phenyl compound layer covering the carbon layer.

[0057] In the embodiment of the present application, a silicon-based material is provided, and the silicon-based inner core is obtained aft...

Embodiment 1

[0067] A method for preparing a silicon-based negative electrode material, comprising:

[0068] 1kg of silicon-oxygen material (SiO, D 50 5 μm) into a vapor deposition furnace, under the protection of argon atmosphere, the temperature was raised to 950°C, 1000sccm of ethylene was passed in, after 5 hours of heat preservation, the introduction of ethylene was stopped, and the temperature was naturally cooled to room temperature under the argon atmosphere, and the powder Carrying out crushing and sieving to obtain a carbon layer-coated silicon-oxygen material.

[0069] Dissolve 50g of 4-vinylphenylacetic acid in 800mL of N-methylpyrrolidone, add 950g of carbon-coated silicon-oxygen material, stir and disperse evenly, and then heat to 120°C to completely volatilize the organic solvent to obtain a black powder. Then the above black powder was dried at -0.09MPa, 120°C for 2h to obtain the primary silicon-based negative electrode material. Finally, sieving and iron removal are car...

Embodiment 2

[0071] A method for preparing a silicon-based negative electrode material, comprising:

[0072] 1kg of silicon-oxygen material (SiO, D 50 5 μm) into a vapor deposition furnace, under the protection of argon atmosphere, the temperature was raised to 950°C, and 2000 sccm of ethylene was introduced, and after 8 hours of heat preservation, the introduction of ethylene was stopped, and the temperature was naturally cooled to room temperature under an argon atmosphere, and the powder Carrying out crushing and sieving to obtain a carbon layer-coated silicon-oxygen material.

[0073] Dissolve 20g of 4-vinylphenylacetic acid in 800mL of N-methylpyrrolidone, add 980g of carbon-coated silicon-oxygen material, stir and disperse evenly, and then heat to 120°C to completely volatilize the organic solvent to obtain a black powder. Then the above black powder was dried at -0.09MPa, 120°C for 2h to obtain the primary silicon-based negative electrode material. Finally, sieving and iron remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com