Automatic egg tart forming equipment for batch production

An automatic molding and mass production technology, which is applied to dough molding machinery or equipment, disc-shaped dough molding, application, etc., can solve the problems of single function of equipment and low degree of automation, and achieve convenient feeding, convenient production, and loading The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

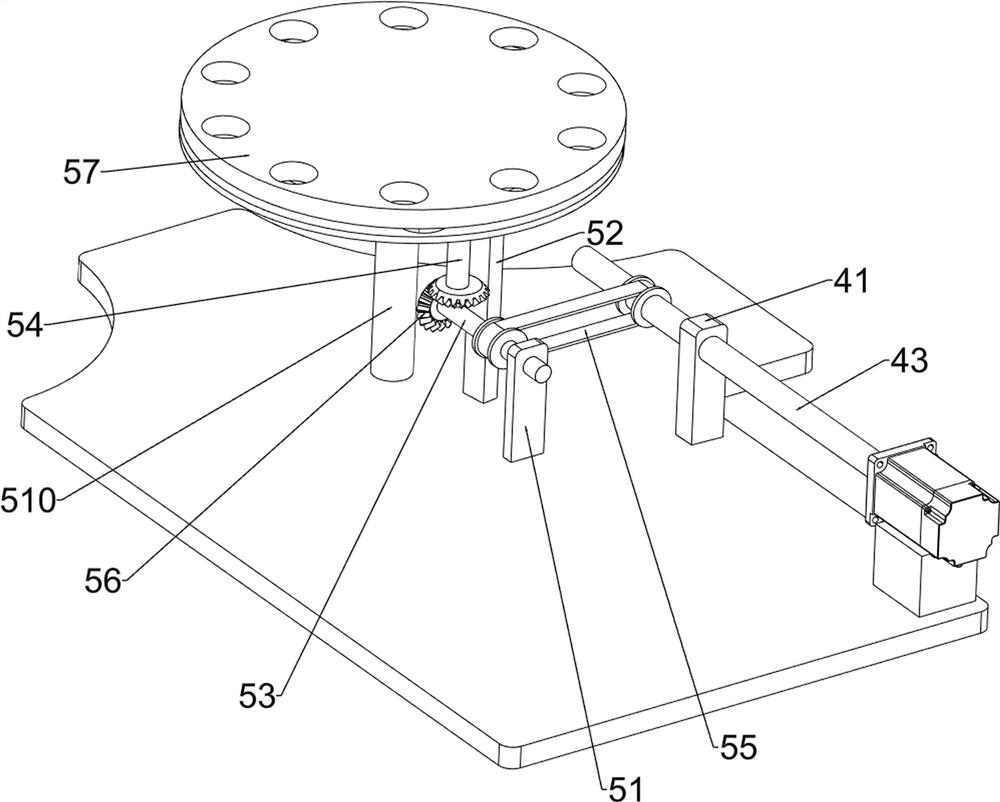

[0088] A kind of egg tart automatic forming equipment for mass production, such as Figure 1-4 As shown, it includes a base plate 1, a first support column 2, a motor 3, an extruding mechanism 4 and a rotation mechanism 5, the first support column 2 is provided on the front right side of the top of the base plate 1, and the motor is provided on the top of the first support column 2. 3. An extruding mechanism 4 is arranged in the middle on the right side of the top of the bottom plate 1, and the extruding mechanism 4 is connected with the motor 3, and a rotating mechanism 5 is arranged in the middle of the top of the bottom plate 1.

[0089] When it is necessary to make egg tarts, the staff puts the tin foil box into the rotating mechanism 5, and puts the dough cake in the tin foil box, then controls the motor 3 to rotate clockwise, drives the rotating mechanism 5 to rotate clockwise, and drives the extrusion mechanism at the same time 4. Continuously move up and down. When the...

Embodiment 2

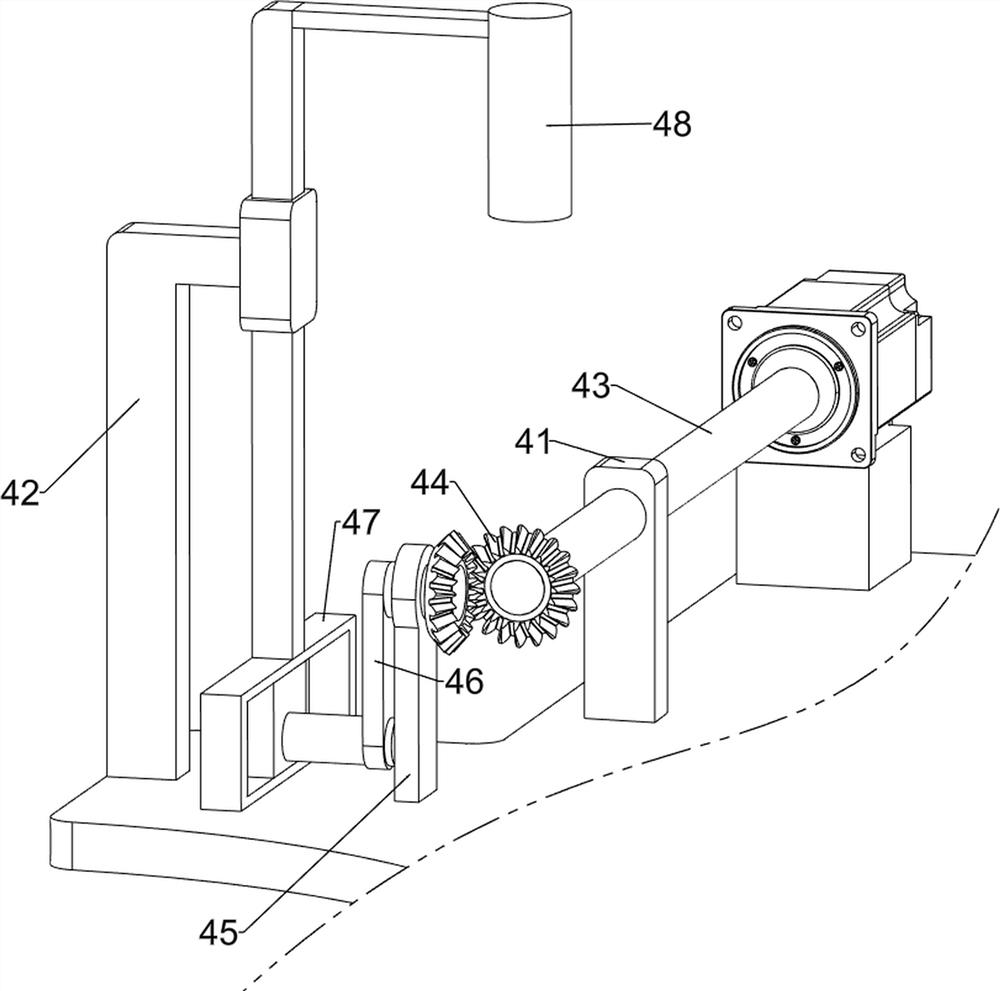

[0091] On the basis of Example 1, such as Figure 2-4 As shown, the extrusion mechanism 4 includes a second support column 41, a third support column 42, a first rotating shaft 43, a first bevel gear 44, a fourth support column 45, a connecting rotating rod 46, a first chute 47 and a press Block 48, the right side of the bottom plate 1 top is provided with a second support column 41, the rear side of the motor 3 is provided with a first rotating shaft 43, the first rotating shaft 43 is rotationally connected with the second support column 41, and the right side of the bottom plate 1 top is provided with a fourth The supporting column 45, the fourth supporting column 45 top is rotatably provided with a connecting rotating rod 46, the connecting rotating rod 46 and the rear part of the first rotating shaft 43 are all provided with a first bevel gear 44, and the two first bevel gears 44 mesh, and the base plate 1 The top right rear part is provided with the 3rd support column 42,...

Embodiment 3

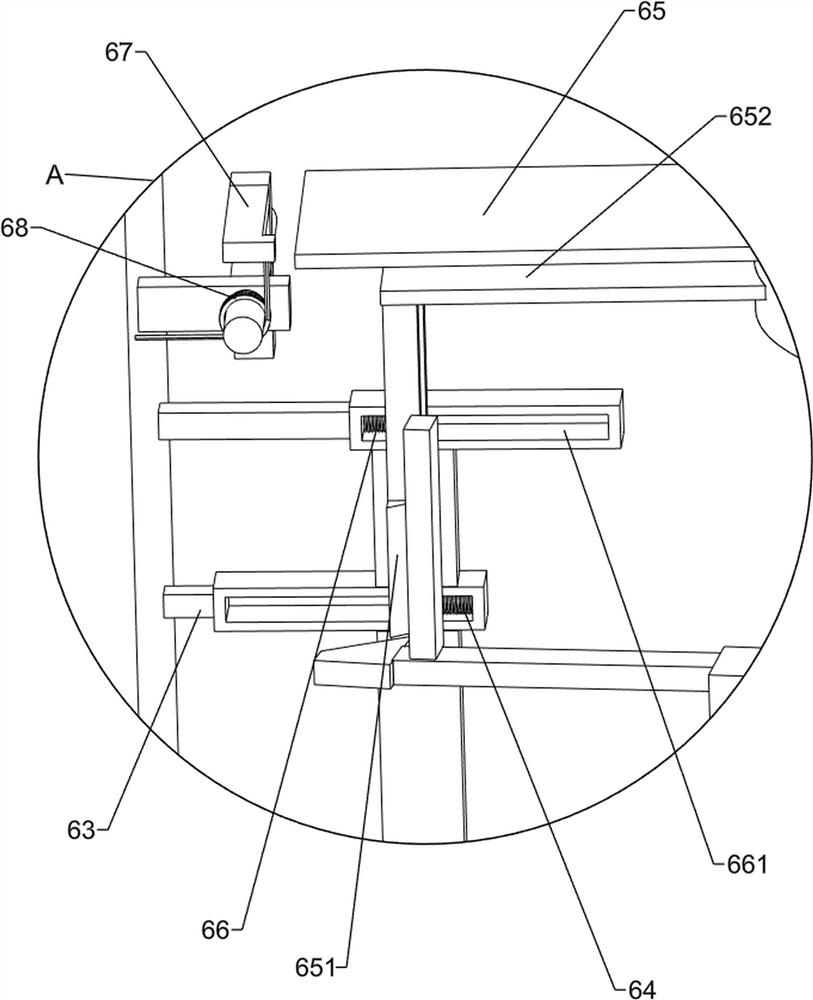

[0096] On the basis of Example 2, such as Figure 5-9 As shown, a tin foil box feeding mechanism 6 is also included, and the tin foil box feeding mechanism 6 includes a seventh support column 61, an eighth support column 62, a first slide rail 63, a first spring 64, and a second clamping block. 65. Wedge block 651, isolation plate 652, second spring 66, second slide rail 661, push block 67, torsion spring 68, third block 69 and tin foil box tube 610. Seven support columns 61, the eighth support column 62 is arranged on the lower right side of the seventh support column 61, the third block 69 is evenly arranged on the top of the turntable 57, the second slide rail 661 is arranged on the upper right side of the seventh support column 61, The second sliding rail 661 is a front-side sliding second clamping block 65, a second spring 66 is provided between the left side of the second clamping block 65 and the second sliding rail 661, and a first sliding rail is provided on the upper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap