Food rotary conveying device and method thereof

A technology of rotary conveying and conveying device, applied in conveyor control device, heating device, conveyor, etc., can solve problems such as inconvenience for diners to pick up, affecting sales of snacks, steam burns, etc., to reduce steam diffusion, avoid The effect of scalding customers and optimizing the dining environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

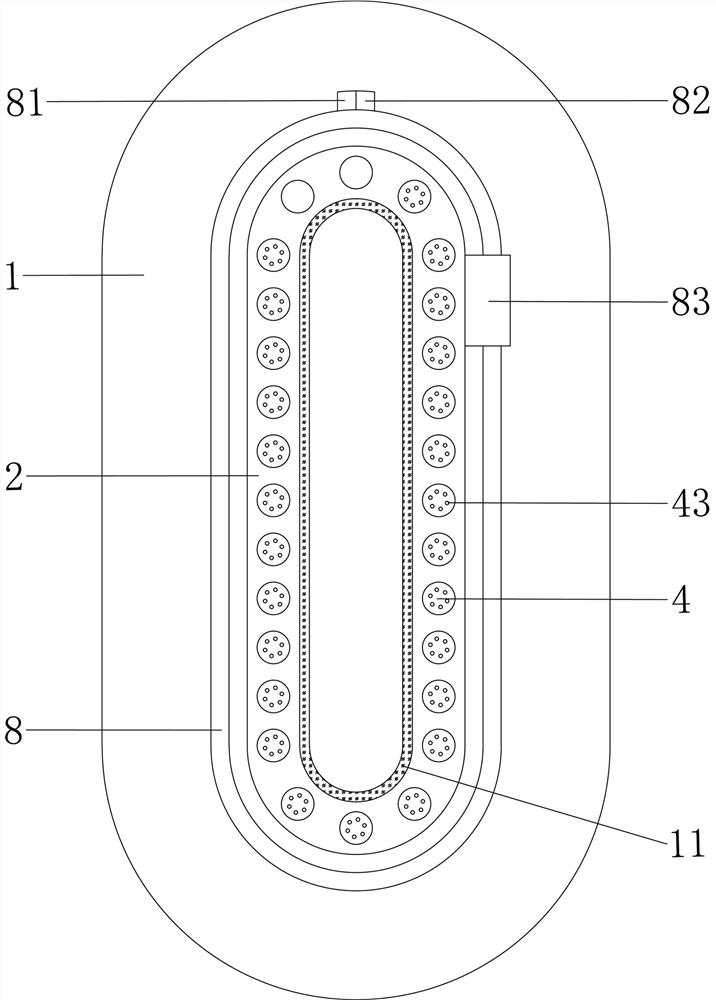

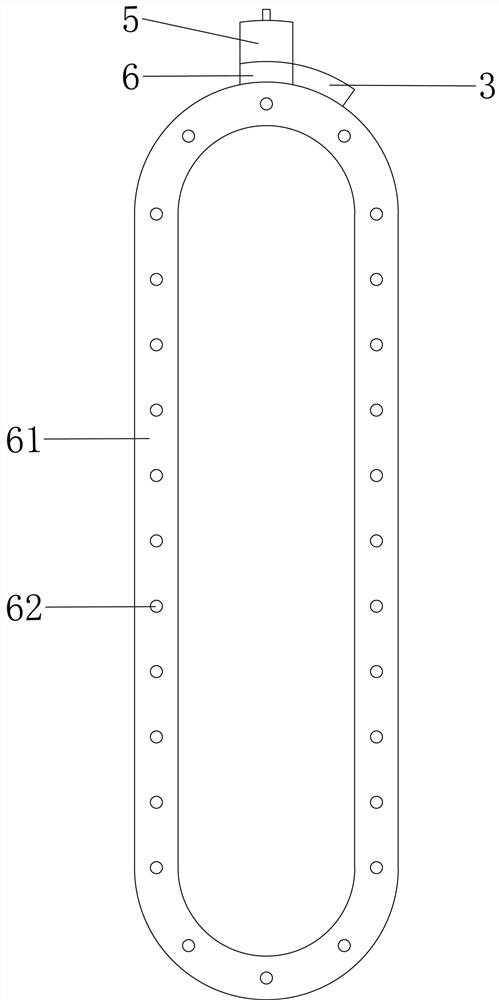

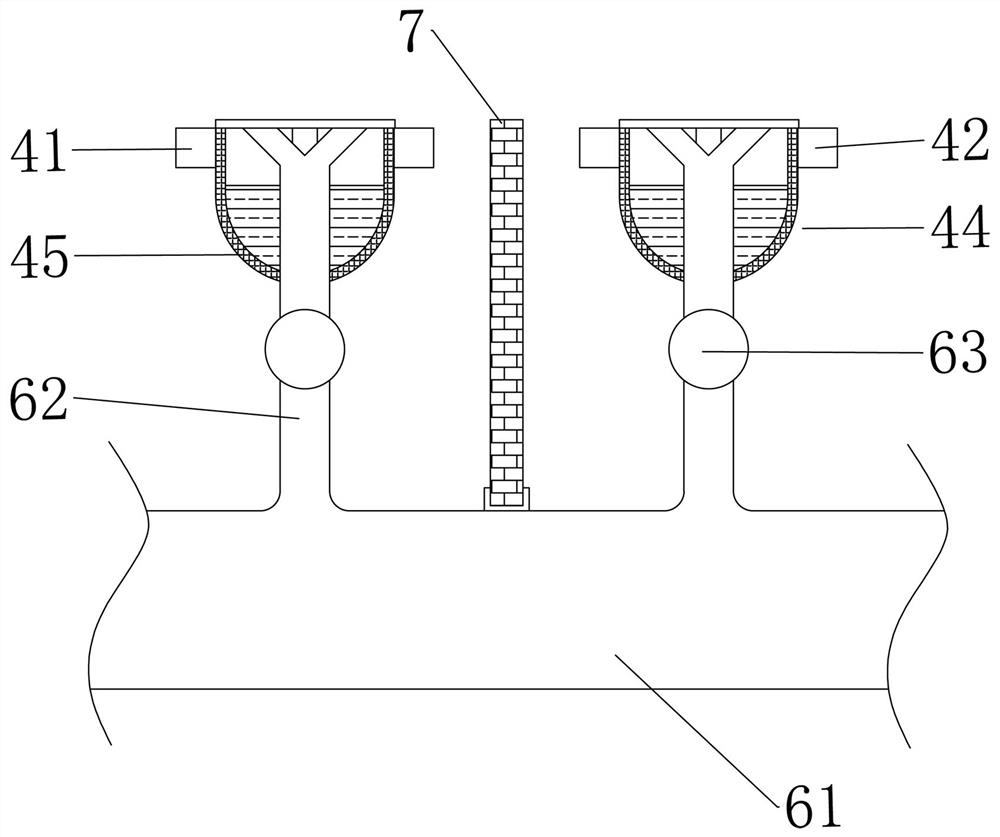

[0042] A food rotary transmission device, comprising an installation table 1, a conveyor belt 2 installed on the installation table 1, and a first power unit 3 for driving the conveyor belt 2, the conveyor belt 2 is provided with a plurality of snack placement seats 4, the snack The placement base 4 is provided with a temperature sensor 41 and a gravity sensor 42, and the installation table 1 is provided with a water filtering device 5, and the water filtering device 5 is connected with a steam generating device 6, and the steam generating device 6 is connected with a steam main pipe 61, the steam main pipe 61 is provided with several steam branch pipes 62.

[0043] The steam branch pipe 62 is provided with an independent valve 63 , and the independent valve 63 is electrically connected with the temperature sensor 41 and the gravity sensor 42 .

[0044] The snack placing base 4 is provided with a plurality of ventilation holes 43 connected with the steam branch pipe 62 .

[0...

Embodiment 2

[0048] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0049] The installation table 1 is equipped with a fixed-point conveyor belt 8, the fixed-point conveyor belt 8 is electrically connected with a fixed-point control module 81 and a second power device 82 for driving the fixed-point transmission belt 8, and the fixed-point conveyor belt is provided with no less than one transmission seat 83.

[0050] The fixed-point conveyor belt 8 is arranged above the conveyor belt 2 .

Embodiment 3

[0052] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0053] The installation table 1 is equipped with a fixed-point conveyor belt 8, the fixed-point conveyor belt 8 is electrically connected with a fixed-point control module 81 and a second power device 82 for driving the fixed-point transmission belt 8, and the fixed-point conveyor belt is provided with no less than one transmission seat 83.

[0054] The fixed-point conveyor belt 8 is arranged on one side of the conveyor belt 2 , and the fixed-point conveyor belt 8 is near the outer edge of the installation table 1 , and the height of the fixed-point conveyor belt 8 is lower than that of the conveyor belt 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com