Catalytic ozonation device and method for treating coal chemical concentrated solution

A technology of ozone catalytic oxidation and ozone oxidation, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problem of insufficient contact between catalysts and wastewater, increased wastewater treatment costs, waste of ozone and catalysts, etc. problems, to achieve the effect of convenient operation, increasing utilization rate and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] After the ozone pre-oxidation treatment is completed, the present invention replaces the packing plate in the stirring blade of the main agitator with the packing plate filled with activated iron shavings, and carries out the first-stage catalytic ozonation under the stirring conditions of the main agitator and the auxiliary agitator deal with. In the present invention, the filling rate of the activated iron shavings in the filler board is preferably 30-60%; the preparation method of the activated iron shavings preferably includes the following steps: performing alkali washing and pickling on the iron shavings in sequence to obtain the activated iron shavings; The alkaline cleaning agent for alkaline cleaning is preferably sodium hydroxide solution, and the concentration of the sodium hydroxide solution is preferably 1 to 1.5 mol / L, more preferably 1.3 to 1.4 mol / L, and the time for the alkaline cleaning is preferably 22~24h, more preferably 21~23h; The pickling agent f...

Embodiment 1

[0058] The wastewater is taken from the effluent of reverse osmosis concentrate of a coal-to-gas project. The main indicators of the wastewater are COD 297.3mg / L, pH 7.7, UV 254 is 6.520.

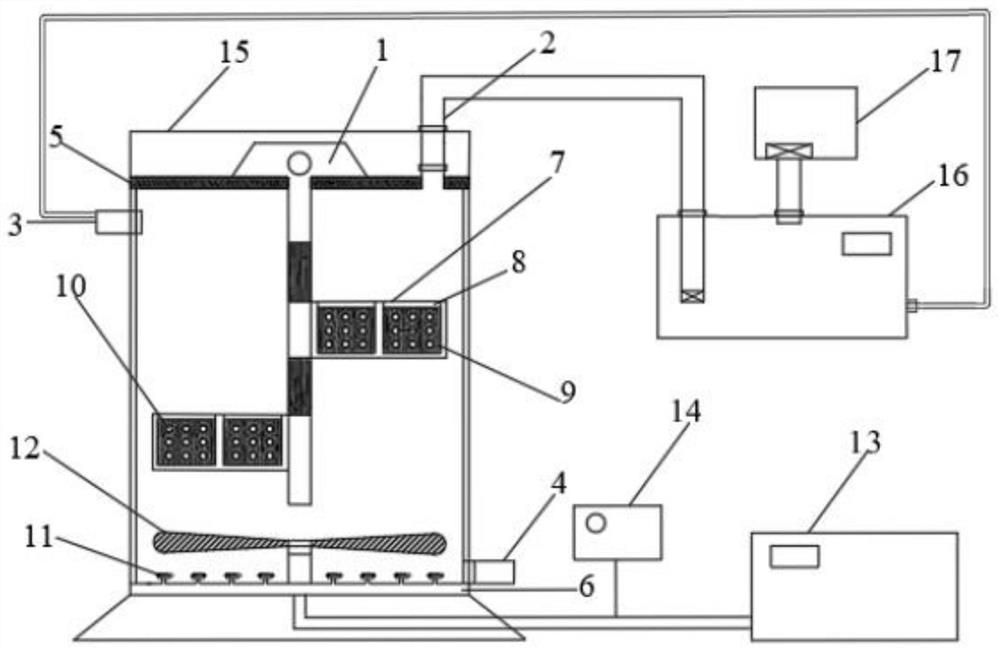

[0059] use figure 1 The device in is used to treat wastewater, wherein: the reaction chamber is cylindrical, the length of the main shaft of the main agitator is 3 / 4 of the height of the reaction chamber, the length of the stirring blade is 3 / 4 of the radius of the reaction chamber, the height is 8cm, and the width of the main agitator is 1 / 6 of the height, 4 stirring blades; the length of the main shaft of the auxiliary agitator is 1 / 5 of the height of the reaction chamber; the number of microporous aerators is 16, and the number of holes on the packing plate is 9.

[0060] The processing steps are as follows:

[0061] Use sodium hydroxide to adjust the pH value of the coal gasification wastewater to 9, first install a packing plate without a catalyst in the blade of the main agitator, a...

Embodiment 2

[0070] The wastewater is taken from the biochemical secondary effluent of a coal-to-gas project. The main indicators of the wastewater are COD 451.0mg / L, pH 7.4, UV 254 is 6.920.

[0071] use figure 1The device in is used to treat wastewater, wherein: the reaction chamber is cylindrical, the length of the main shaft of the main agitator is 3 / 4 of the height of the reaction chamber, the length of the stirring blade is 3 / 4 of the radius of the reaction chamber, the height is 10cm, and the width of the main agitator is 1 / 6 of the height, 4 stirring blades; the length of the main shaft of the auxiliary agitator is 1 / 5 of the height of the reaction chamber; the number of microporous aerators is 16, and the number of holes on the packing plate is 9.

[0072] The processing steps are as follows:

[0073] Use sodium hydroxide to adjust the pH value of the coal gasification wastewater to 9, first install a packing plate without a catalyst in the blade of the main agitator, and perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com