Preparation method and product of concrete applied to wind power plant

A technology for concrete and wind farms, applied in the field of concrete preparation, can solve the problems of increased cost, high fibers and admixtures, and achieve the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

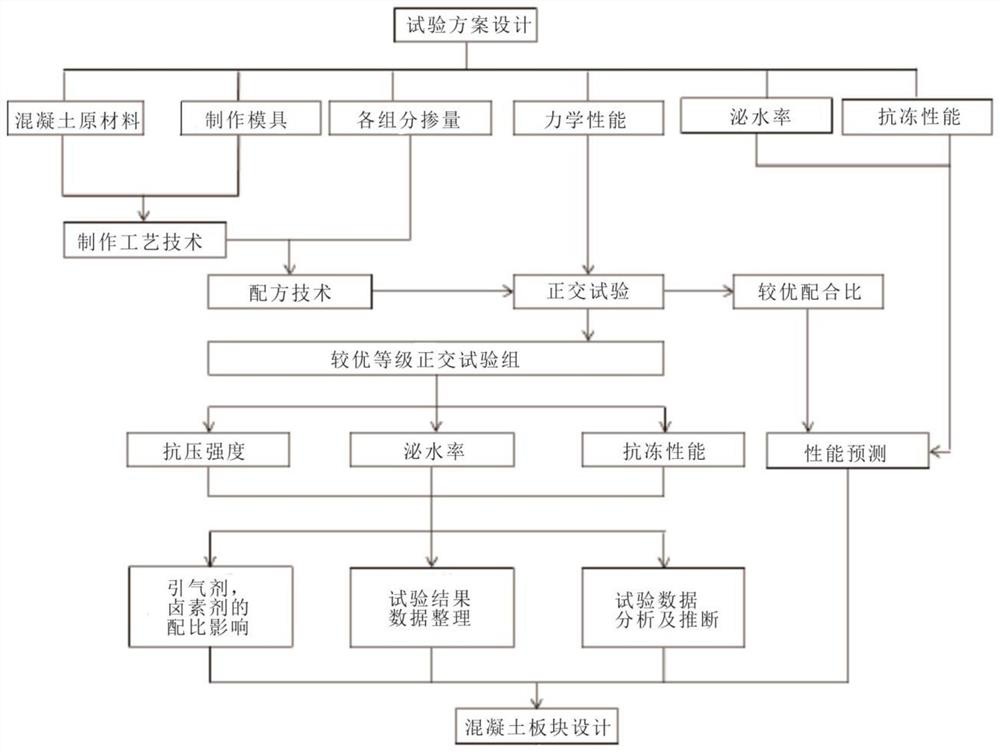

Method used

Image

Examples

preparation example Construction

[0029]A method for preparing concrete based on wind farm applications, comprising the following steps: 1) taking 5 to 10 parts of air-entraining agent and 10 to 12 parts of halogen agent in 10 parts of clear water in terms of mass parts of raw materials to form a modified Aqueous solution; 2) Add 9-10 parts of pozzolan and 30-37 parts of cement to the modified aqueous solution respectively; 3) Add 35-40 parts of sand and 35-40 parts of gravel with a particle size of 5-10 mm in sequence, and mix well Prepare the slurry; 4) Add 3 to 4 parts of fiber to the slurry; 5) Pouring the slurry into the area to form, ensuring that the fibers are wrapped in the slurry and distributed as symmetrically as possible; 6) Hot air curing; Get concrete.

[0030] Among them, the fiber is plant straw, and the moisture content of the straw is not more than 15%; the air-entraining agent is sodium dodecylbenzenesulfonate, triterpene saponin, polyethylene glycol, nonionic polyacrylamide, sodium stearat...

Embodiment 1

[0041] The present invention optimizes the ratio of air-entraining agent preparation. Because it is beneficial to further reduce the bleeding rate of concrete, and at the same time enhance the compressive strength of concrete, the bleeding rate and compressive strength are used as indicators for determination.

[0042] A method for preparing concrete based on wind farm applications. Each component is made according to the above steps. In order to ensure a single variable, the air-entraining agent is extracted according to the following test in terms of raw material mass parts, and the ratio of other raw materials is as follows: Take 11 parts The halogen agent is placed in 10 parts of clear water to form a modified aqueous solution; after adding 10 parts of pozzolan and 35 parts of cement to the modified aqueous solution, 37 parts of sand and 37 parts of gravel with a particle size of 5 to 10 mm are added in sequence, and mixed to produce The slurry is obtained, and 3 parts of ...

Embodiment 2

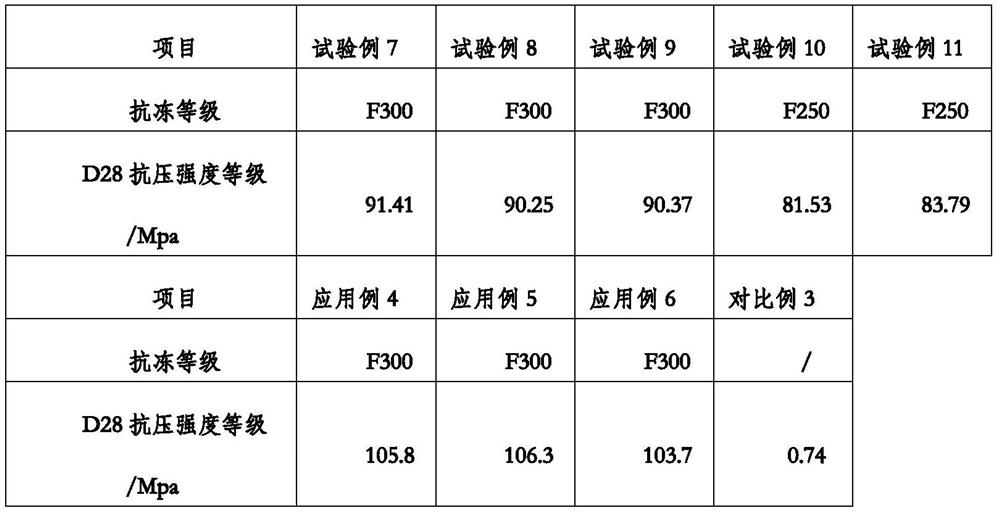

[0067] The present invention prefers the ratio of the halogen agent. Because it can make the magnesium cement hardened body produce high strength and has excellent low temperature resistance, it is measured with low temperature resistance and compressive strength as indicators.

[0068] A method for preparing concrete based on the application of wind farms. Each component is produced according to the above steps. In order to ensure a single variable, the halogen agent is extracted according to the following test in terms of raw material mass parts, and the ratio of other raw materials is as follows: Take 7.5 parts of lead The air agent is placed in 10 parts of clear water to form a modified aqueous solution; after adding 10 parts of pozzolan and 35 parts of cement to the modified aqueous solution, 37 parts of sand and 37 parts of gravel with a particle size of 5 to 10 mm are added in sequence, and mixed to produce The slurry is obtained, and 3 parts of fibers are added to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com