A kind of propylene-conjugated diene copolymer and preparation method thereof

A technology of conjugated diene and copolymer, applied in the field of preparation of propylene copolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

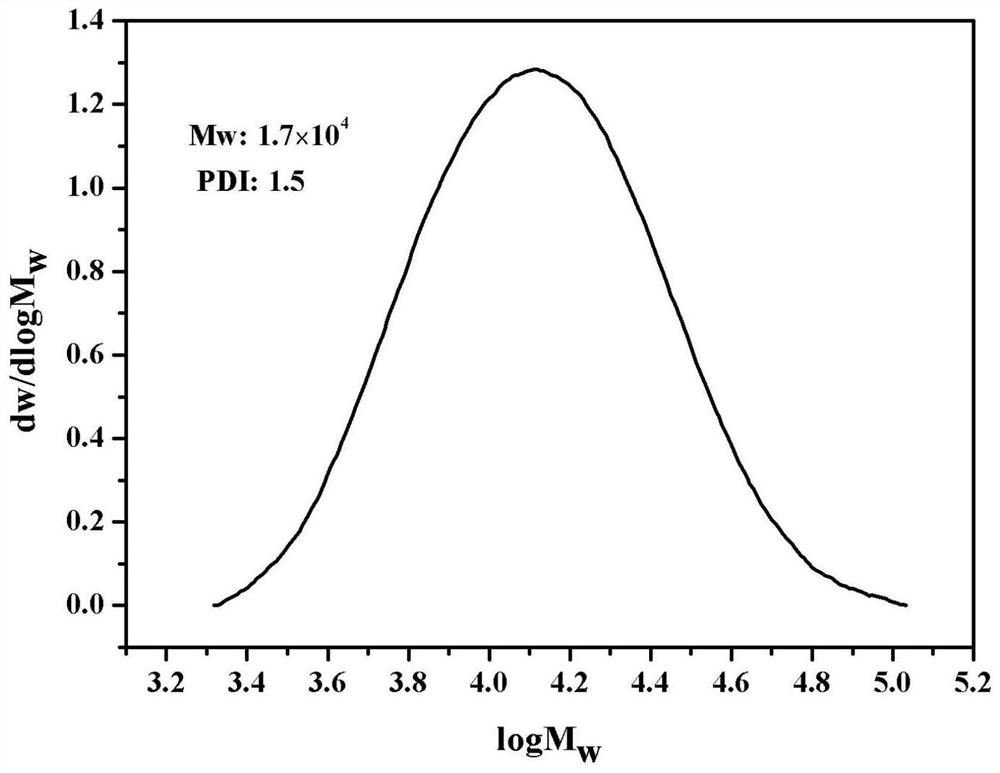

Embodiment 1

[0054] Under anhydrous and oxygen-free conditions, using toluene as a solvent, the reactor is filled with a metal catalyst system, the temperature in the reactor is controlled at 25°C, and the pressure is 0.1MPa, and propylene gas is passed into the reactor for polymerization reaction. The reaction time 2min to obtain the hard segment structure of propylene homopolymer; while maintaining the propylene gas feed, feed butadiene gas to make butadiene and propylene carry out copolymerization reaction under the metal catalyst system, the reaction time is 8min, for The mixed solution obtained after terminating the reaction is precipitated, filtered, and dried to obtain a propylene-butadiene copolymer.

[0055] Among them, the metal catalyst system includes:

[0056] A. Ethyl bridged dichlorodiindene zirconium complex catalyst;

[0057] B. Triethylaluminum, the effect of triethylaluminum is to handle the reactor;

[0058] C.[Ph 3 C][B(C 6 f 5 ) 4 ] activator;

[0059] The mola...

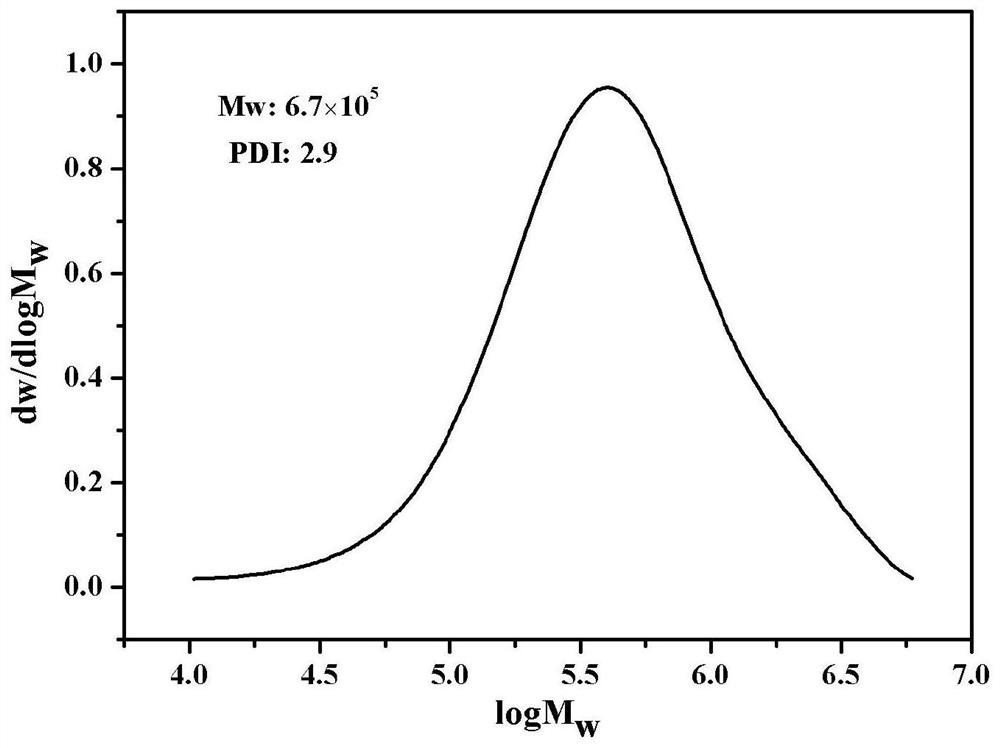

Embodiment 2

[0063] Under anhydrous and oxygen-free conditions, using toluene as a solvent, the reactor is filled with a metal catalyst system, the temperature in the reactor is controlled at 25°C, and the pressure is 0.1MPa, and propylene gas is passed into the reactor for polymerization reaction. The reaction time 2min to obtain the hard segment structure of propylene homopolymer; while maintaining the propylene gas feed, feed butadiene gas to make butadiene and propylene carry out copolymerization reaction under the metal catalyst system, the reaction time is 8min, for The mixed solution obtained after terminating the reaction is precipitated, filtered, and dried to obtain a propylene-butadiene copolymer.

[0064] Among them, the metal catalyst system includes:

[0065] A. Lutidine imine hafnium metal complex catalyst;

[0066] B. Triisobutylaluminum, the effect of triisobutylaluminum is to handle the reactor;

[0067] C.[Ph 3 C][B(C 6 f 5 ) 4 ] activator;

[0068] The molar rati...

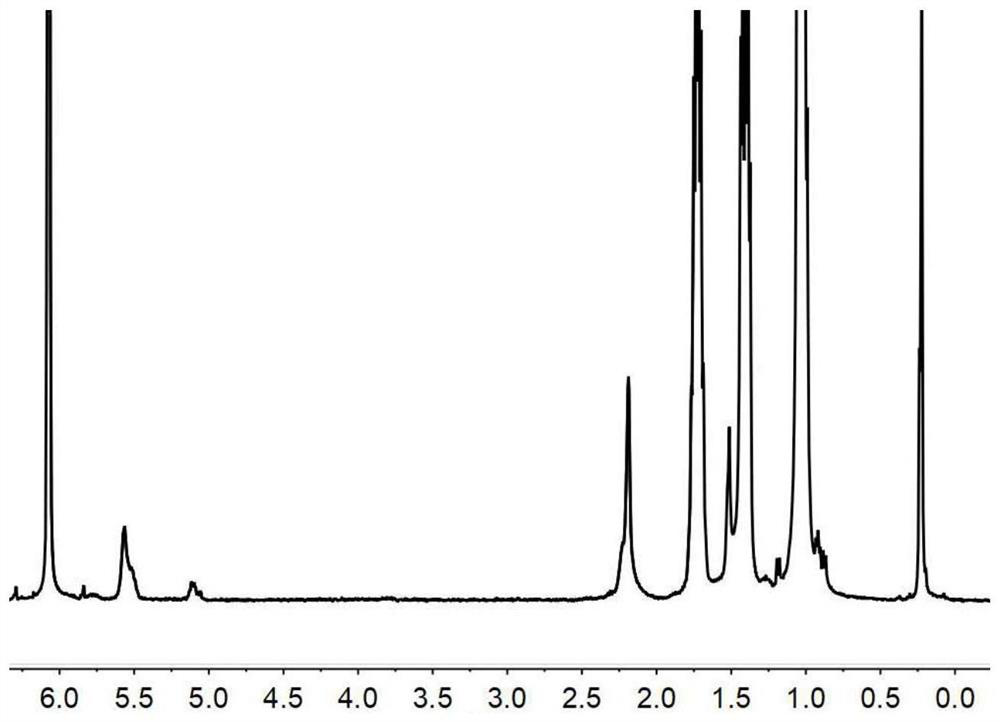

Embodiment 3

[0076] Under anhydrous and oxygen-free conditions, using chlorobenzene as a solvent, the reactor is filled with a metal catalyst system, the temperature in the reactor is controlled at 20°C, and the pressure is 0.1MPa, and propylene gas is passed into the reactor for polymerization reaction. The time is 1min, and the hard segment structure of propylene homopolymer is obtained; while the propylene gas is kept flowing, the isoprene gas is passed into, so that the isoprene and propylene are copolymerized under the metal catalyst system, and the reaction time is After 3 minutes, the mixed solution obtained after terminating the reaction was precipitated, filtered, and dried to obtain a propylene-isoprene copolymer.

[0077] Among them, the metal catalyst system includes:

[0078] A. β-diketoimine titanium metal complex catalyst;

[0079] B. Isobutyl aluminoxane, the role of isobutyl aluminoxane is to treat the reactor and activate the catalyst;

[0080] The molar ratio of isobut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com