Preparation method for extracting peptide chelated calcium through combined conversion of enzymolysis and chelation

A technology of chelating calcium and enzymatic hydrolysis, applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of environmental pollution, waste of calcium and protein resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

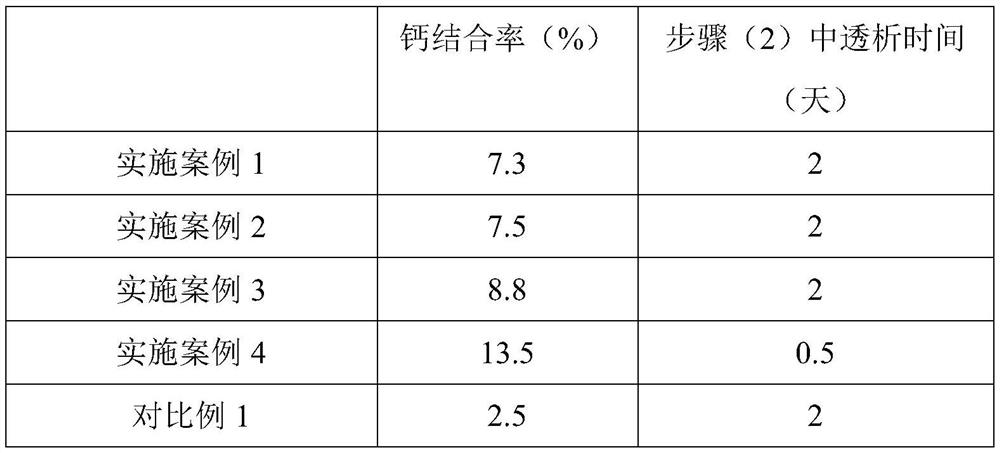

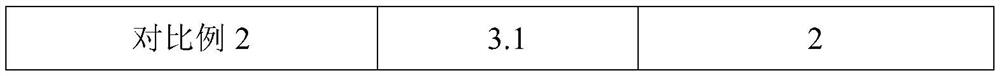

Examples

Embodiment 1

[0027] Example 1: Preparation of salted egg white peptide chelated calcium by phosphorylation of sodium tripolyphosphate

[0028] A preparation method for enzymatic hydrolysis and chelation combined transformation to extract peptide chelated calcium, said method comprising the following steps:

[0029] (1) Wash and crush the eggshells, pass through a 150-mesh sieve, and then perform ball milling for 13 hours at a speed of 400r / min, a material-to-liquid ratio of 1:2, and a ball-to-material ratio of 5:1.

[0030] (2) Add 5000U / g of protease to the salted egg white, the protease is flavor protease, the reaction temperature is 50°C, and the pH value is 7. After the reaction is carried out for 3 hours, the peptide is obtained by inactivating the enzyme, and the peptide is dissolved in 0.02mol / L, pH value of 7.4 phosphate buffer solution (disodium hydrogen phosphate and sodium dihydrogen phosphate), to prepare a 0.01mol / L protein solution. Adjust the pH to 7.5, add sodium tripolyph...

Embodiment 2

[0033] Embodiment 2: Salted egg white peptide chelated calcium prepared by sodium tripolyphosphate phosphorylation

[0034] A preparation method for enzymatic hydrolysis and chelation combined transformation to extract peptide chelated calcium, said method comprising the following steps:

[0035] (1) Wash and crush the eggshells, pass through a 150-mesh sieve, and then perform ball milling for 13 hours at a speed of 400r / min, a material-to-liquid ratio of 1:2, and a ball-to-material ratio of 5:1.

[0036] (2) Add 5000U / g of protease to the salted egg white, the protease is flavor protease, the reaction temperature is 51°C, and the pH value is 7. After the reaction is carried out for 3 hours, the peptide is obtained by inactivating the enzyme, and the peptide is dissolved in 0.02mol / L, pH value of 7.4 phosphate buffer solution, prepared into 0.01mol / L protein solution. Adjust the pH to 7.5, add sodium tripolyphosphate (STP) to 2%, react at 30°C, and react for 1 hour to obtain ...

Embodiment 3

[0039] Example 3: Preparation of Salted Egg White Peptide Chelated Calcium by Phosphorylation with Sodium Pyrophosphate

[0040] A preparation method for enzymatic hydrolysis and chelation combined transformation to extract peptide chelated calcium, said method comprising the following steps:

[0041] (1) Wash and crush the eggshells, pass through a 150-mesh sieve, and then perform ball milling for 13 hours at a speed of 400r / min, a material-to-liquid ratio of 1:2, and a ball-to-material ratio of 5:1.

[0042] (2) Add 5000U / g of protease to the salted egg white, the protease is flavor protease, the reaction temperature is 51°C, and the pH value is 7. After the reaction is carried out for 3 hours, the peptide is obtained by inactivating the enzyme, and the peptide is dissolved in 0.02mol / L, pH value of 7.4 phosphate buffer solution, prepared into 0.01mol / L protein solution. Adjust pH to 3, add sodium pyrophosphate to 2%, reaction temperature to 80° C., and reaction time to 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com