Preparation of amorphous surface modified layered double hydroxide hierarchical heterostructure electrocatalyst

A surface modification layer, double hydroxide technology, applied in electrodes, electrolysis process, electrolysis components and other directions, can solve problems such as high technical requirements, industrial application impact, complex methods and processes, achieve low technical requirements, and easy to promote , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

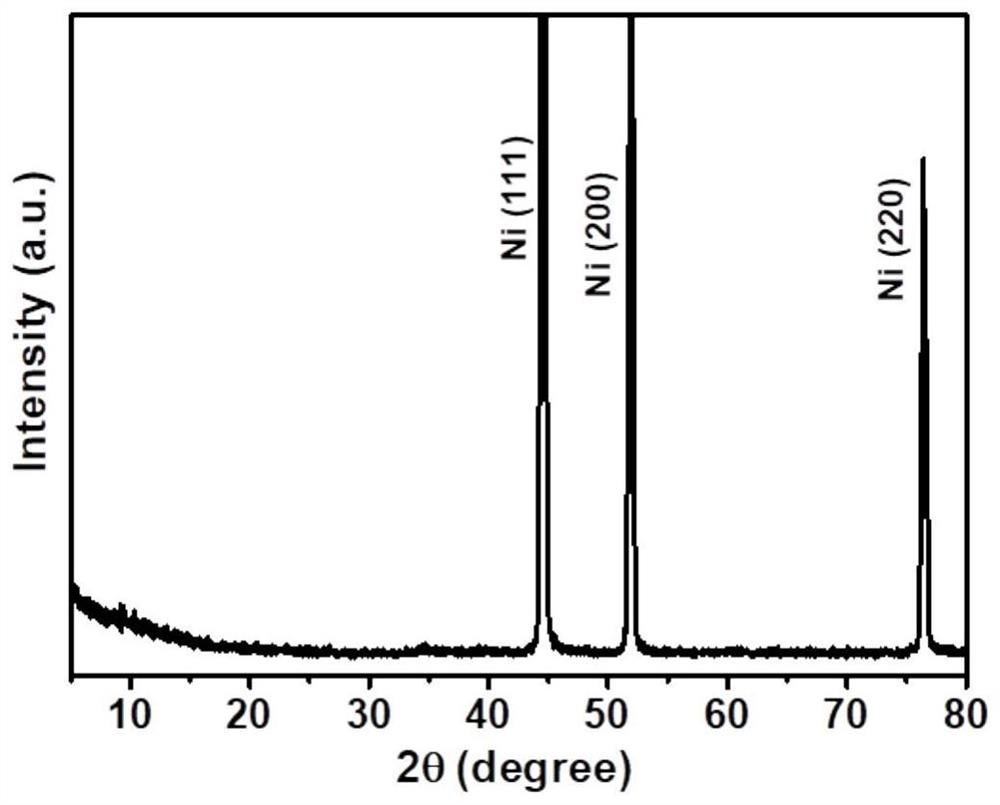

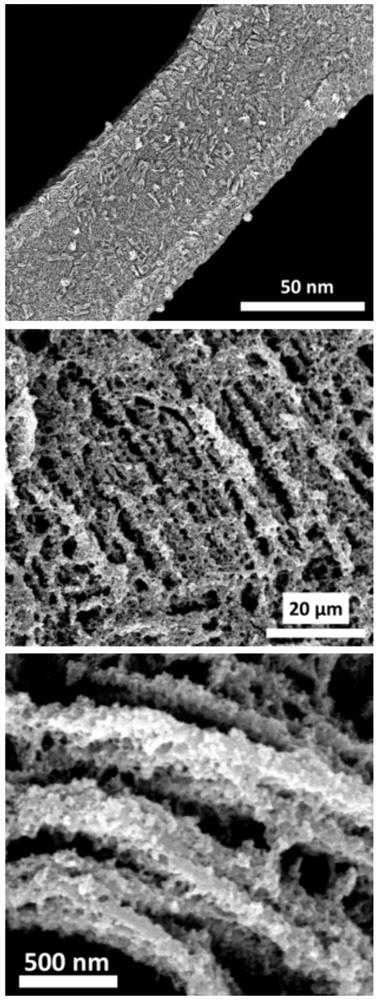

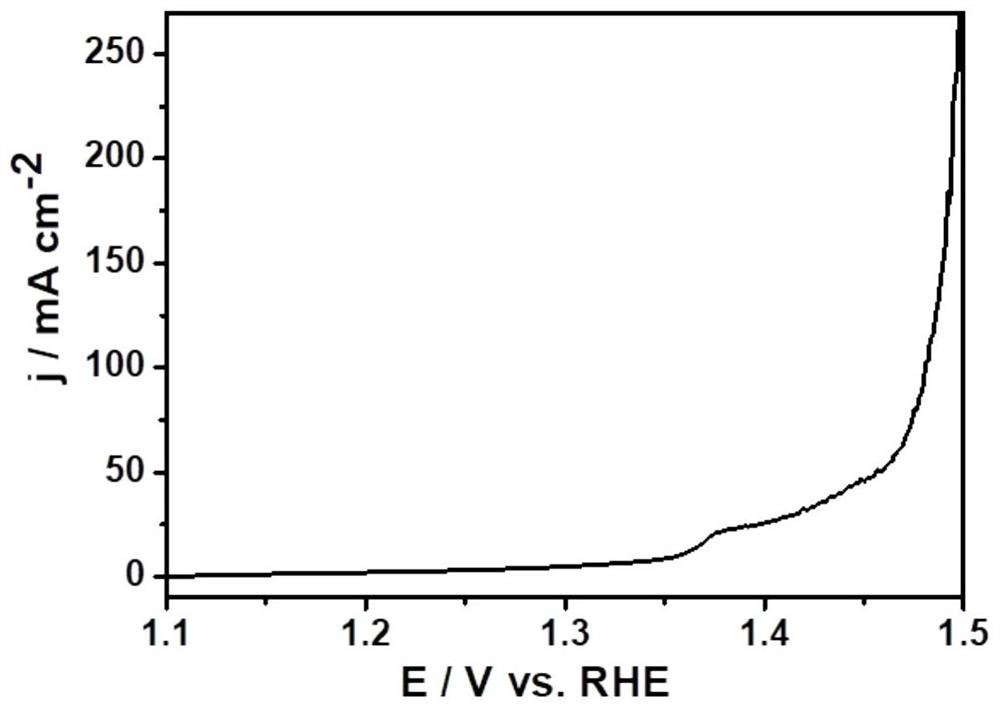

[0023] A preparation of an amorphous surface-modified layered double hydroxide hierarchical heterostructure electrocatalyst, specifically comprising the following steps:

[0024] (1) 0.8mmol of CoCl 2 ·6H 2 O, 0.4mmol of AlCl 3 ·6H 2 The ammonium fluoride of 0.4mmol and the urea of 28mmol are dissolved in the deionized water of 40ml, after magnetic stirring 30min, obtain mixed solution;

[0025] (2) mixed solution is moved into the high-pressure hydrothermal reaction kettle that volume is 50ml, then adds foamed nickel in the still, the size of foamed nickel is 2cm * 3cm, foamed nickel is before putting into autoclave, with deionized water and Ultrasonic cleaning with ethanol for 5 minutes, then seal the autoclave and put it in an oven, react at 100°C for 3 hours, take out the foamed nickel after cooling to room temperature naturally, and wash the foamed nickel with deionized water and absolute ethanol three times respectively Then put it into a vacuum drying oven and kee...

Embodiment 2

[0028] A preparation of an amorphous surface-modified layered double hydroxide hierarchical heterostructure electrocatalyst, specifically comprising the following steps:

[0029] (1) 0.8mmol of CoCl 2 ·6H 2 O, 0.4mmol of AlCl 3 ·6H 2 The ammonium fluoride of 0.4mmol and the urea of 28mmol are dissolved in the deionized water of 40ml, after magnetic stirring 30min, obtain mixed solution;

[0030] (2) mixed solution is moved into the high-pressure hydrothermal reaction kettle that volume is 50ml, then adds foamed nickel in the still, the size of foamed nickel is 2cm * 3cm, foamed nickel is before putting into autoclave, with deionized water and Ultrasonic cleaning with ethanol for 5 minutes, then seal the autoclave and put it in an oven, react at 100°C for 3 hours, take out the foamed nickel after cooling to room temperature naturally, and wash the foamed nickel with deionized water and absolute ethanol three times respectively Then put it into a vacuum drying oven and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com