Treatment system and treatment method for papermaking sludge of recycled paper

A papermaking sludge and treatment system technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high humidity, difficult use of soil amendments, and air-drying of sludge General level etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-5 The application is described in further detail.

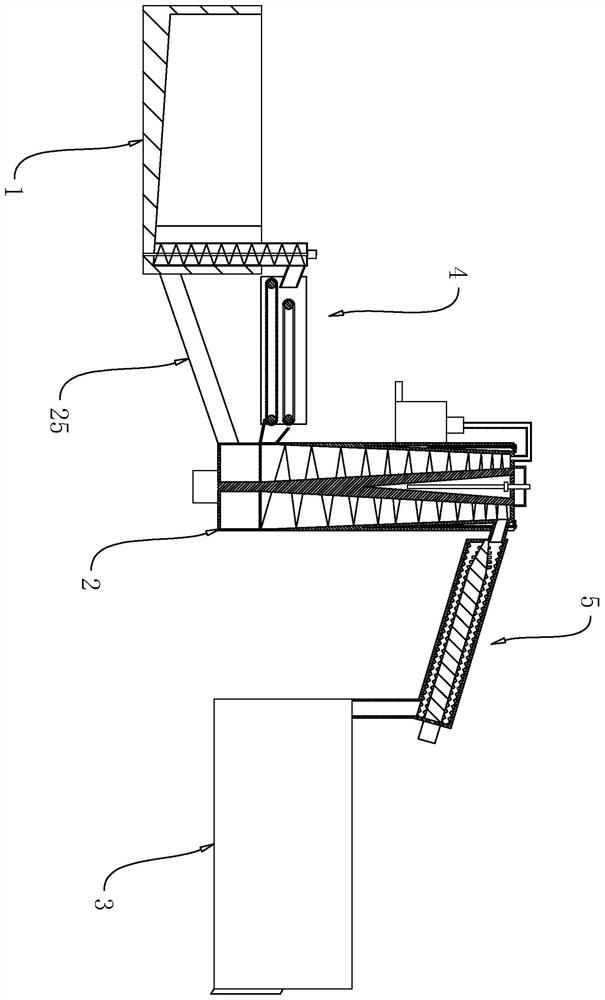

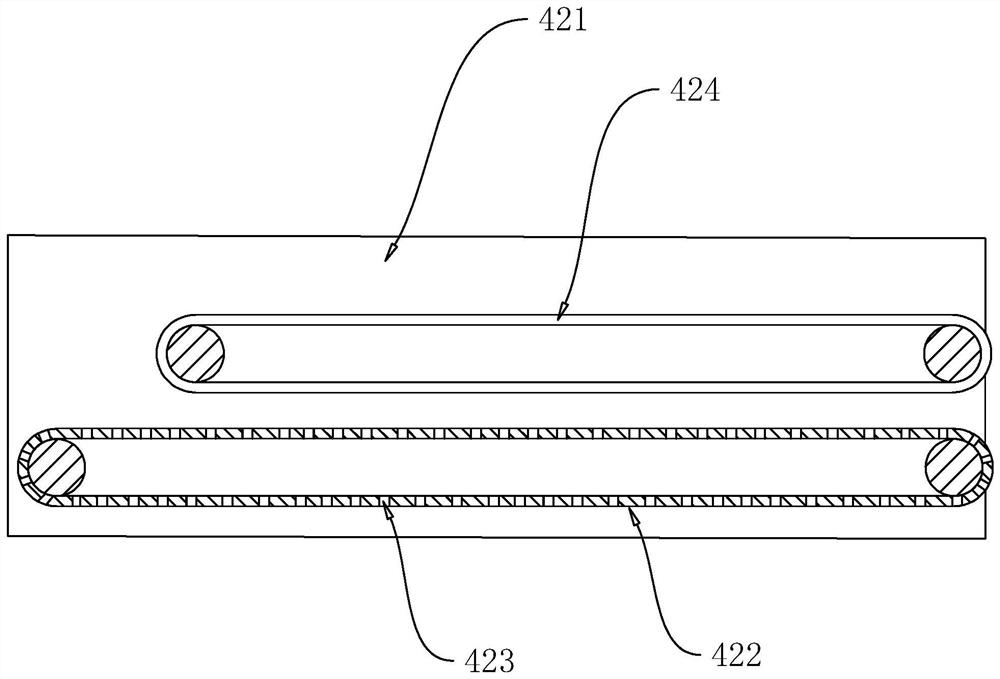

[0047] The embodiment of the present application discloses a papermaking sludge treatment system for recycled paper, which includes a sedimentation tank 1 , a filter press device 2 and a drying device 3 arranged in sequence.

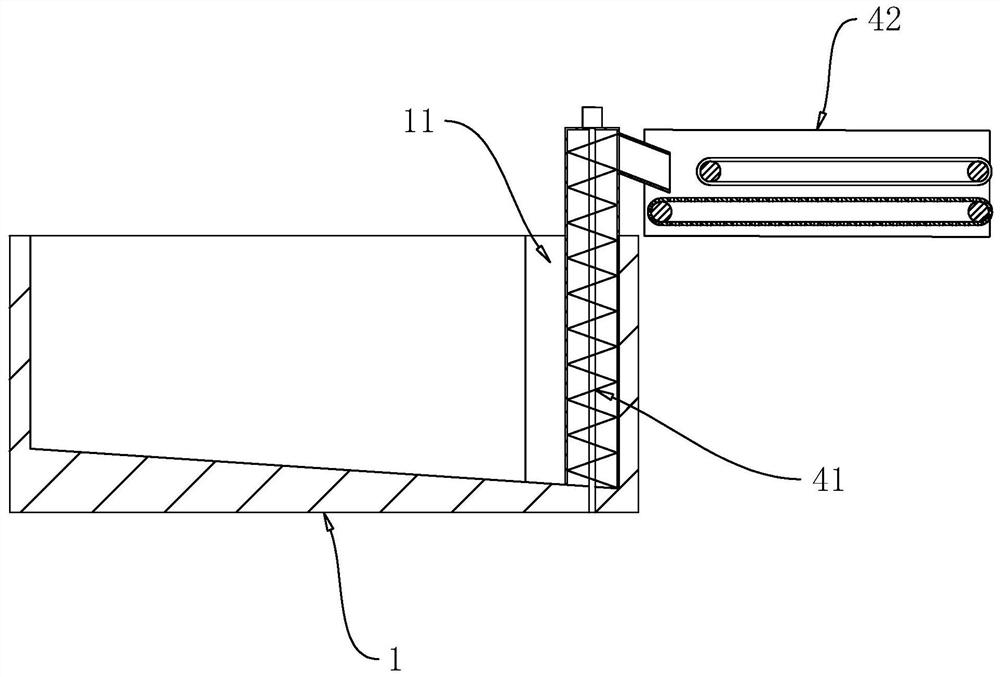

[0048] The sedimentation tank 1 has a rectangular shape, and the bottom surface of the sedimentation tank 1 is inclined downward along its length direction. One end of the sedimentation tank 1 corresponding to the lower position of the bottom surface forms two mutually fixed inclined plates 11, and the two inclined plates 11 are close to each other. One side tends to be inclined away from the sedimentation tank 1, so that the sedimentation tank 1 forms an accumulation part in front of the two inclined plates, which facilitates the accumulation of settled sludge.

[0049] The filter press equipment 2 is placed on the upper side of one end of the accumulation pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap