Monocapped amphiphilic organosiloxane macromer, silicone hydrogel, contact lens and preparation method

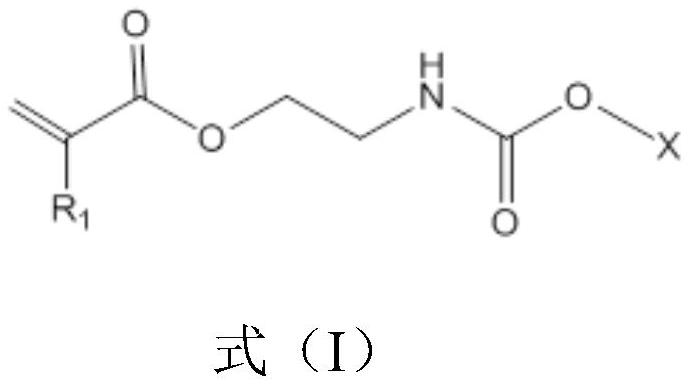

A technology of organosiloxane and macromolecular monomers, which is applied in glasses/goggles, instruments, optics, etc. It can solve the problems of strong hydrophobicity on the surface of silicone hydrogel, affecting the wearing comfort of lenses, and limited dosage , to achieve the effects of being beneficial to eye health, excellent oxygen permeability and light transmission, and reducing the degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Preparation of Mono-terminated Amphiphilic Organosiloxane Macromers

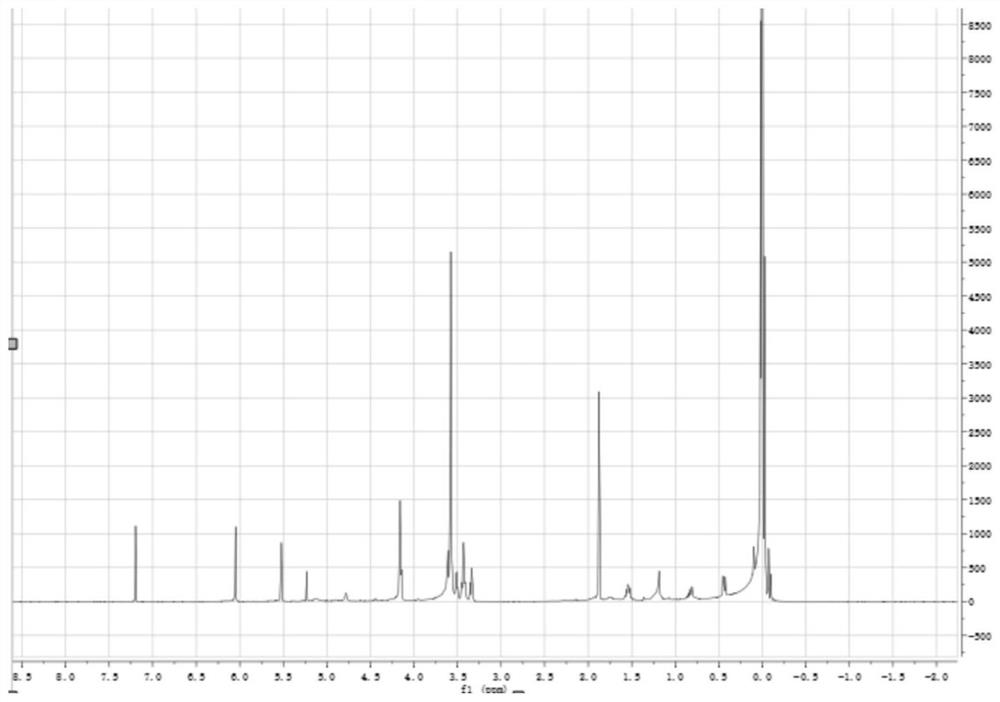

[0073] Get HO-PDMS (number average molecular weight is about 1500, wherein m is about 7, n is about 16, purchased from Nanjing Fuqun Chemical Co., Ltd.) 30g, add 50mL dichloromethane (CH 2 Cl 2 ) and 0.1 g of dibutyltin dilaurate, stir and mix well. Then weigh the corresponding proportions of IEM and CH 2 Cl 2 Mix, add a constant pressure dropping funnel, add IEM and CH to the reaction dropwise 2 Cl 2 mixture. At the same time, the constant temperature water bath heating device was turned on, the temperature was adjusted to 55 °C, and the reaction was carried out for 10 h. After the reaction, rotary steam at 50°C for 30 min to obtain an organosiloxane macromonomer, denoted as M1-w1. figure 1 It is the nuclear magnetic spectrum of the single-end-capped amphiphilic organosiloxane macromonomer (M1-w1) prepared in Example 1.

[0074]

Embodiment 2

[0076] Preparation of Mono-terminated Amphiphilic Organosiloxane Macromers

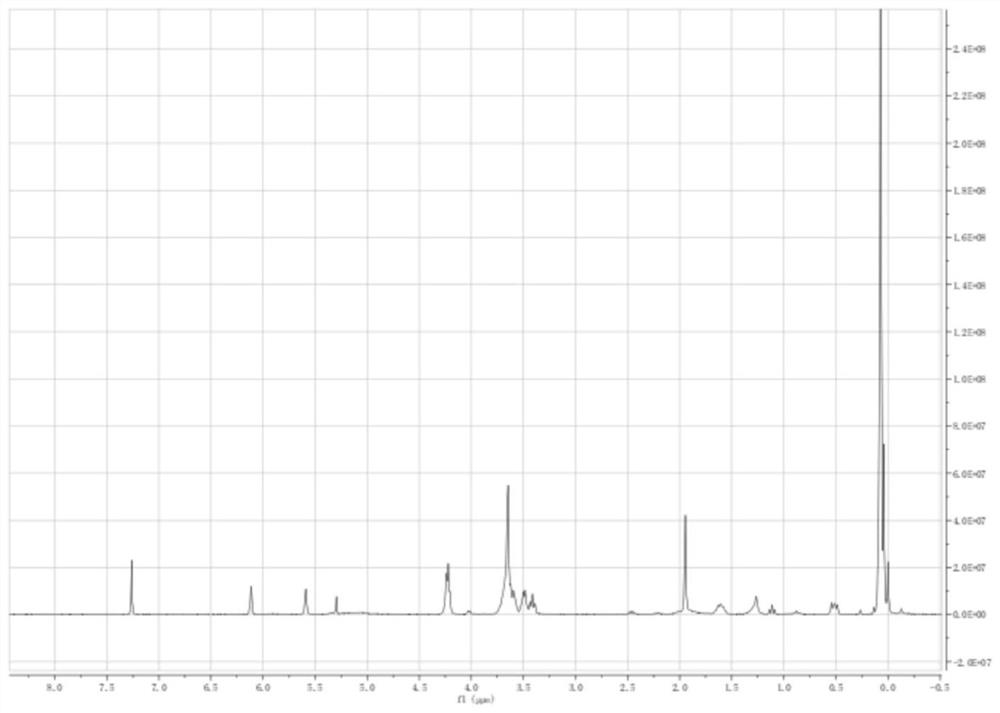

[0077]Get HO-PDMS (number average molecular weight is about 5500, wherein m is about 11, n is about 50, purchased from Nanjing Fuqun Chemical Co., Ltd.) 50g, add 80mL CH 2 Cl 2 and 0.2g dibutyltin dilaurate, stir and mix well. Then weigh the corresponding proportions of IEM and CH 2 Cl 2 Mix, add a constant pressure dropping funnel, add IEM and CH to the reaction dropwise 2 Cl 2 mixture. At the same time, the constant temperature water bath heating device was turned on, the temperature was adjusted to 55 °C, and the reaction was carried out for 10 h. After the reaction, the reaction was completed by rotary steaming at 50 °C for 30 min to obtain an organosiloxane macromonomer, denoted as M1-w2. figure 2 is the nuclear magnetic spectrum of the single-end-capped amphiphilic organosiloxane macromonomer (M1-w2) prepared in Example 2.

[0078]

Embodiment 3-4

[0080] A silicone hydrogel prepared by polymerization of the following components:

[0081] 40 parts of mono-terminated amphiphilic organosiloxane macromonomers,

[0082] Methyl-bis(trimethylsiloxane)-silyl

[0083] 20 parts of propyl glycerol methacrylate (SIGMA),

[0084] 20 parts of hydroxyethyl methacrylate (HEMA),

[0085] 5 parts of N-vinylacetamide (NVA),

[0086] 15 parts of hydroxypropyl methacrylate (HPMA),

[0087] 0.5 part of 2-hydroxy-2-methylpropiophenone (D1173),

[0088] 0.5 part of ethylene glycol dimethacrylate (EGDMA),

[0089] Among them, the single-end-capped amphiphilic organosiloxane macromonomer was prepared by Example 1 and Example 2, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com