Synthesis method of non-corrosive acrylate rubber

A technology of acrylate and synthesis method, which is applied in the field of acrylate rubber preparation, and can solve the problems of slow vulcanization, poor processability of rollers, shortening the service life of processing molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

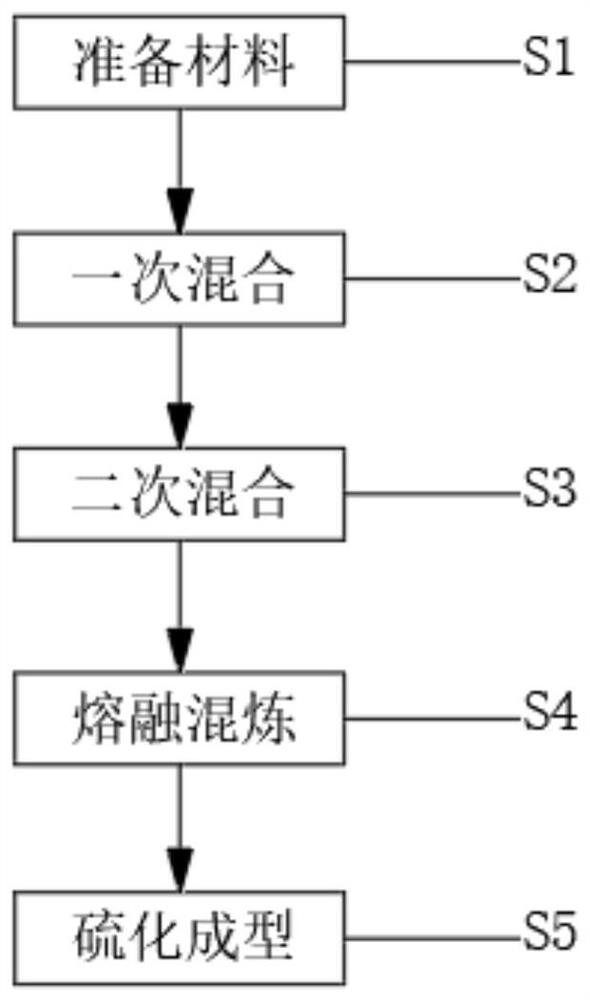

[0024] see figure 1 , the synthetic method of a kind of non-corrosion type acrylate rubber of the present invention, comprises the following steps:

[0025] S1: Preparation materials: prepare 10-35 parts of ethyl acrylate rubber, 15-25 parts of ethyl acrylate rubber, 20-45 parts of diene rubber, 5-12 parts of allyl glycidyl ether solution, and glycidyl methacrylate 4-8 parts of solution, 2-5 parts of reinforcing agent, 3-10 parts of accelerator, 2-8 parts of anti-aging agent, 1-3 parts of anti-scorch agent, 5-13 parts of lubricant, 4-8 parts of plasticizer , 4-6 parts of antioxidant, 5-6 parts of flame retardant, 4-6 parts of compatibilizer, 4-12 parts of emulsifier, 4-10 parts of initiator, 3-5 parts of molecular weight regulator and 5-5 parts of coagulant 20 backups;

[0026] S2: Primary mixing: 10-35 parts of ethyl acrylate rubber, 15-25 parts of ethyl acrylate rubber, 20-45 parts of diene rubber, 2-5 parts of reinforcing agent, 3-10 parts of accelerator and compatibilize...

Embodiment 1

[0032] A kind of synthetic method of non-corrosion type acrylate rubber, comprises the following steps:

[0033] S1: Prepare materials: Prepare 10 parts of ethyl acrylate rubber, 15 parts of ethyl acrylate rubber, 20 parts of diene rubber, 5 parts of allyl glycidyl ether solution, 4 parts of glycidyl methacrylate solution, and 2 reinforcing agents 3 parts, 3 parts of accelerator, 2 parts of anti-aging agent, 1 part of anti-scorch agent, 5 parts of lubricant, 4 parts of plasticizer, 4 parts of antioxidant, 5 parts of flame retardant, 4 parts of compatibilizer, 4 parts of emulsifier , 4 parts of initiator, 3 parts of molecular weight regulator and 5 parts of coagulant for standby;

[0034] S2: One-time mixing: put 10 parts of ethyl acrylate rubber, 15 parts of ethyl acrylate rubber, 20 parts of diene rubber, 2 parts of reinforcing agent, 3 parts of accelerator and 4 parts of compatibilizer into the reactor and stir and mix. The temperature in the kettle is set at 35°C, the mixi...

Embodiment 2

[0040] A kind of synthetic method of non-corrosion type acrylate rubber, comprises the following steps:

[0041] S1: Prepare materials: Prepare 35 parts of ethyl acrylate rubber, 25 parts of ethyl acrylate rubber, 45 parts of diene rubber, 12 parts of allyl glycidyl ether solution, 8 parts of glycidyl methacrylate solution, and 5 parts of reinforcing agent 10 parts, accelerator 10 parts, anti-aging agent 8 parts, anti-scorch agent 3 parts, lubricant 13 parts, plasticizer 8 parts, antioxidant 6 parts, flame retardant 6 parts, compatibilizer 6 parts, emulsifier 12 parts , 10 parts of initiator, 5 parts of molecular weight regulator and 20 parts of coagulant for standby;

[0042] S2: One-time mixing: put 35 parts of ethyl acrylate rubber, 25 parts of ethyl acrylate rubber, 45 parts of diene rubber, 5 parts of reinforcing agent, 10 parts of accelerator and 6 parts of compatibilizer into the reactor and stir and mix. The temperature in the kettle is set at 45°C, the mixing reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com