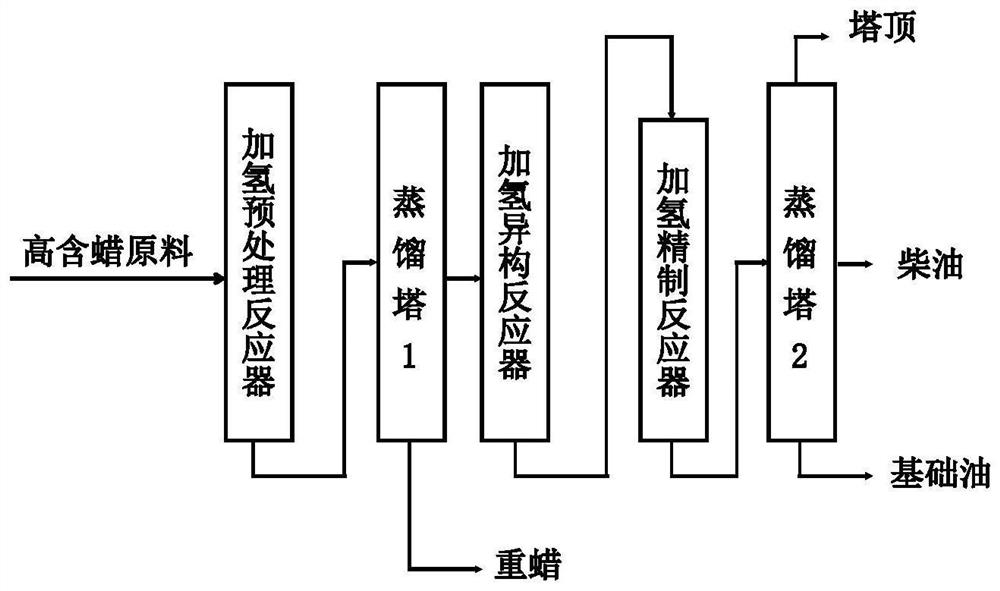

A method for preparing lubricating oil base oil by hydrogenation of high-waxy raw materials

A lubricating oil base oil and raw material oil technology, which is applied in the field of hydrogenation conversion of high-waxy raw materials, can solve the problems of low yield of light and heavy base oils and affect process economy, and achieve strong raw material adaptability and high performance Good, simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

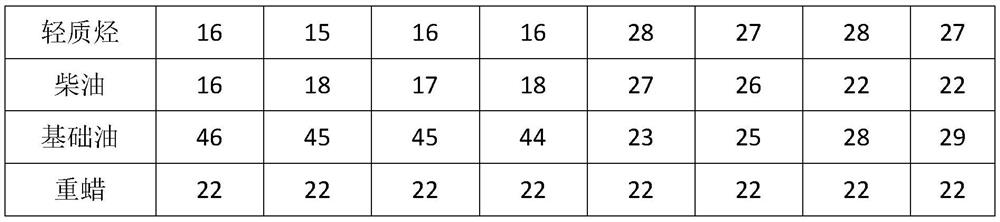

Embodiment 1

[0055] The hydrogenation pretreatment catalyst H1 is used in the hydrogenation pretreatment reactor, and the reaction conditions are 250°C, 4MPa, and the space velocity is 2.0h -1 , the hydrogen-to-oil ratio is 500; the distillation tower 1 separates the heavy oil fraction greater than 550 °C; the hydroisomerization reactor adopts the hydroisomerization catalysts A and B, and the filling method of both is A above B and below, and the filling volume ratio is 2: 1. The reaction conditions are 355°C, 12MPa, and space velocity 0.8h -1 , the ratio of hydrogen to oil is 500; the hydrofinishing reactor adopts hydrofinishing catalyst H2, and the reaction conditions are 220°C, 5MPa, and space velocity 1.0h -1 , Hydrogen oil ratio 500. After the raw materials shown in Table 1 are converted and fractionated by the reaction process, the product yields obtained are shown in Table 2, and the properties of the base oil products are shown in Table 3.

Embodiment 2

[0057] The hydrogenation pretreatment catalyst H1 is used in the hydrogenation pretreatment reactor, and the reaction conditions are 230°C, 4MPa, and the space velocity is 2.0h -1 , the ratio of hydrogen to oil is 600; the distillation tower 1 separates the heavy oil fraction greater than 550 ° C; the hydroisomerization reactor adopts hydroisomerization catalysts A and B, and the filling method of both is A above B and below, and the filling volume ratio is 1: 1. The reaction conditions are 352°C, 13MPa, and space velocity 0.8h -1 , the ratio of hydrogen to oil is 500; the hydrofinishing reactor uses hydrofinishing catalyst H2, and the reaction conditions are 240°C, 6MPa, and space velocity 1.0h -1 , Hydrogen oil ratio 500. After the raw materials shown in Table 1 are converted and fractionated by the reaction process, the product yields obtained are shown in Table 2, and the properties of the base oil products are shown in Table 3.

Embodiment 3

[0059] The hydrogenation pretreatment catalyst H1 is used in the hydrogenation pretreatment reactor, and the reaction conditions are 270°C, 5MPa, and the space velocity is 2.0h -1 , the ratio of hydrogen to oil is 600; the distillation tower 1 separates the heavy oil fraction greater than 550 ° C; the hydroisomerization reactor adopts hydroisomerization catalysts A and B, and the filling method of both is A above B and below, and the filling volume ratio is 1: 2. The reaction conditions are 348°C, 15MPa, and space velocity 0.8h -1 , the ratio of hydrogen to oil is 500; the hydrofinishing reactor uses hydrofinishing catalyst H2, and the reaction conditions are 240°C, 6MPa, and space velocity 1.0h -1 , Hydrogen oil ratio 500. After the raw materials shown in Table 1 are converted and fractionated by the reaction process, the product yields obtained are shown in Table 2, and the properties of the base oil products are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com