Gas impurity removal and hydrolysis composite tank and blast furnace gas fine desulfurization system

A desulfurization system and coal gas refining technology, which is applied in the direction of gas dust removal, combustible gas purification, gas pollutant removal, etc., can solve the problems of high resistance and excessive pressure loss along the gas process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

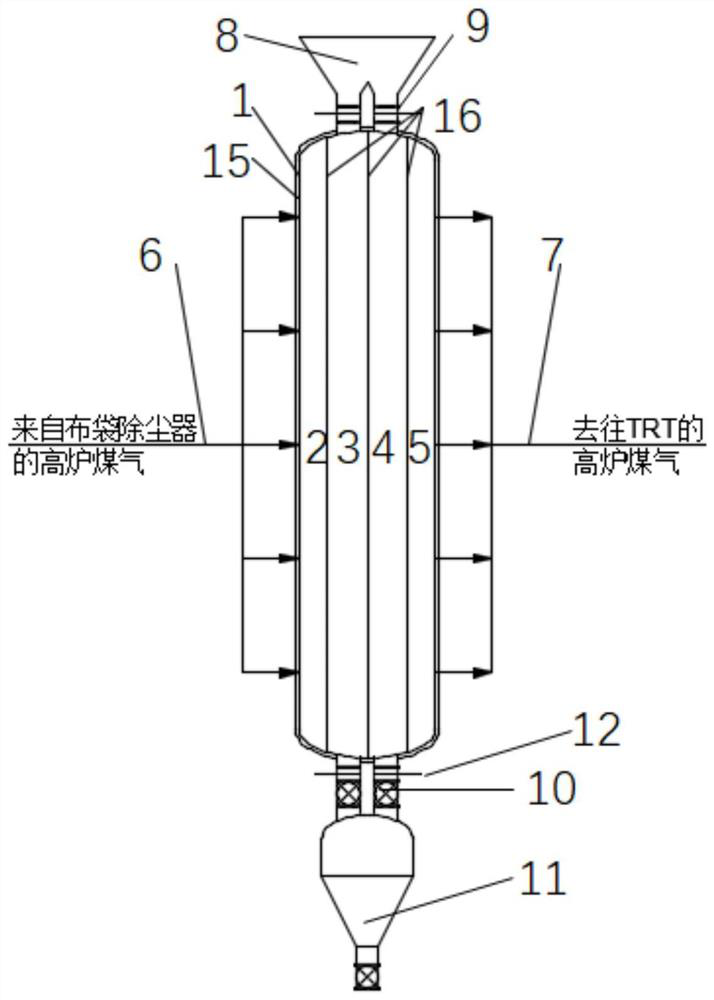

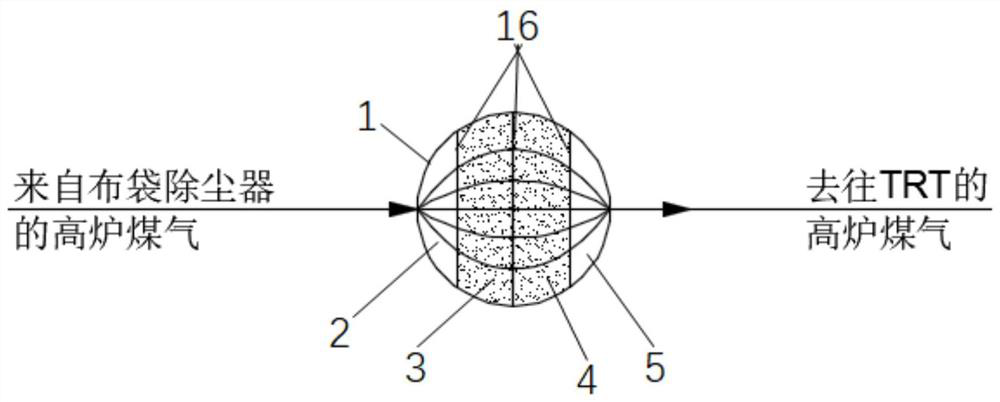

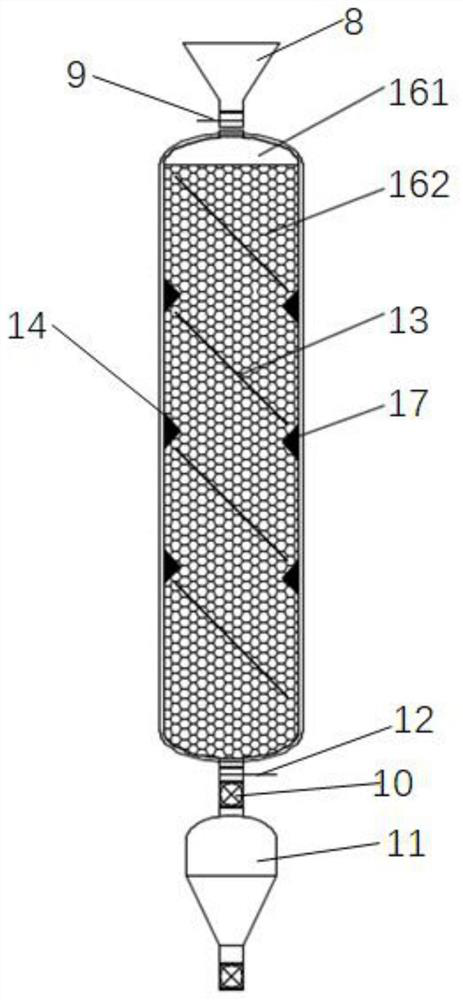

[0033] see figure 1 and figure 2 , a gas de-impurity hydrolysis composite tank, this embodiment is used for fine desulfurization of blast furnace flue gas, of course, it can also be used for other gases, including a reaction tank body 1, and the reaction tank body 1 is provided with a gas inlet 6 and a gas outlet 7 along the radial direction , three mesh partitions 16 are arranged inside the reaction tank body 1, and the mesh partitions 16 are arranged parallel to the center line of the reaction tank, and along the direction of radial gas flow, the mesh partitions 16 divide the interior of the reaction tank body 1 into a gas distribution chamber 2. The impurity removal chamber 3, the catalytic hydrolysis chamber 4 and the gas collection chamber 5, the gas inlet 6 is arranged on the peripheral side of the reaction tank body 1 close to the gas distribution chamber 2, and the gas outlet 7 is arranged on the reaction tank body 1 near the gas collection chamber 5 On the periphera...

Embodiment 2

[0047] like figure 1 , a blast furnace gas fine desulfurization system, including the gas removal and hydrolysis composite tank of the above-mentioned embodiment 1, a bag filter and a residual pressure turbine power generation device (TRT), the flue gas outlet of the bag filter is connected to the gas removal and hydrolysis composite tank The gas inlet 6 of the gas removal and hydrolysis composite tank is connected to the residual pressure turbine power generation device. The blast furnace flue gas is dedusted by the bag filter and then enters the impurity removal and hydrolysis composite tank to convert organic sulfides into easy-to-remove Hydrogen sulfide, and the pressure loss is small, and then the high-pressure blast furnace gas containing hydrogen sulfide generates electricity through the residual pressure turbine power generation device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com