Efficient preparation method of papain preparation

A papain and papain technology, applied in biochemical equipment and methods, enzymes, peptidases, etc., can solve problems such as waste, high water and electricity consumption, and difficulty in adapting to industrialized preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

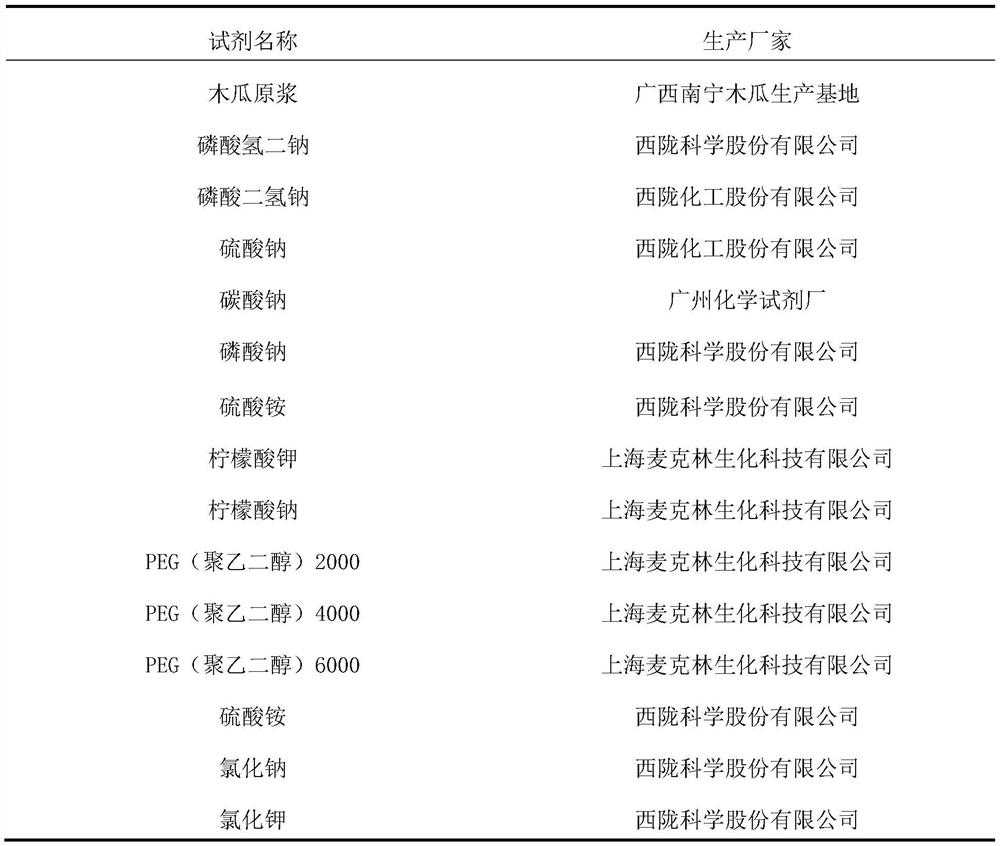

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 of the present invention provides a kind of high-efficiency preparation method of papaya enzyme preparation, and it comprises the following specific operation steps:

[0032] S1, the preparation of papaya enzyme preparation crude product

[0033] Select the fresh papaya collected on the same day to make papaya pulp, and add solid sodium sulfite to the papaya pulp. Adjust the pH to 5.5, and freeze-dry the obtained solution to obtain the crude product of the papaya enzyme preparation;

[0034] S2, preparation of papain crude enzyme product solution and papain lipase crude enzyme product

[0035] Dissolve the crude papaya enzyme preparation prepared in step S1 in L-cysteine solution at 4°C, wherein every 90g of the papain lipase preparation is dissolved in 500mL of L-cysteine solution; using an automatic stirrer After stirring and mixing for 30 minutes, the resulting mixture was centrifuged at a speed of 8000 rpm and the centrifugation time was 20 minute...

Embodiment 2

[0042] Embodiment 2 of the present invention provides a kind of high-efficiency preparation method of papaya enzyme preparation, and it comprises the following specific operation steps:

[0043] S1, the preparation of papaya enzyme preparation crude product

[0044]Select the fresh papaya collected on the same day to make papaya pulp, and add solid sodium sulfite to the papaya pulp. Adjust the pH to 6.0, and freeze-dry the obtained solution to obtain the crude product of the papaya enzyme preparation;

[0045] S2, preparation of papain crude enzyme product solution and papain lipase crude enzyme product

[0046] Dissolve the crude papaya enzyme preparation prepared in step S1 in L-cysteine solution at 4°C, wherein every 90g of the papain lipase preparation is dissolved in 500mL of L-cysteine solution; using an automatic stirrer After stirring and mixing for 50 minutes, the resulting mixed solution was centrifuged at a speed of 12000 rpm and the centrifugation time was 10...

Embodiment 3

[0053] Embodiment 3 of the present invention provides a kind of high-efficiency preparation method of papaya enzyme preparation, and it comprises the following specific operation steps:

[0054] S1, the preparation of papaya enzyme preparation crude product

[0055] Select the fresh papaya collected on the same day to make papaya pulp, and add solid sodium sulfite to the papaya pulp. Adjust the pH to 6.0, and freeze-dry the obtained solution to obtain the crude product of the papaya enzyme preparation;

[0056] S2, preparation of papain crude enzyme product solution and papain lipase crude enzyme product

[0057] Dissolve the crude papaya enzyme preparation prepared in step S1 in L-cysteine solution at 4°C, wherein every 90g of the papain lipase preparation is dissolved in 500mL of L-cysteine solution; using an automatic stirrer After stirring and mixing for 40 minutes, the resulting mixture was centrifuged at a speed of 10,000 rpm and the centrifugation time was 10 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com