Method for preparing high-purity beryllium from industrial beryllium

An industrial, high-purity technology, applied in the direction of improving process efficiency, can solve problems such as adverse environmental impact, complex preparation process lines for high-purity beryllium, secondary pollution of intermediate products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

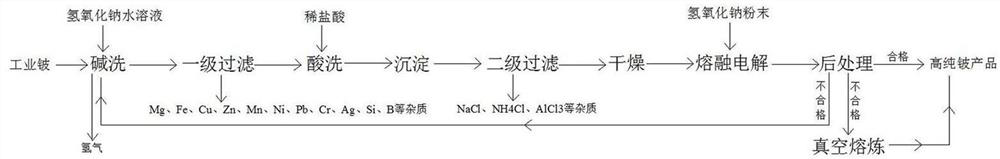

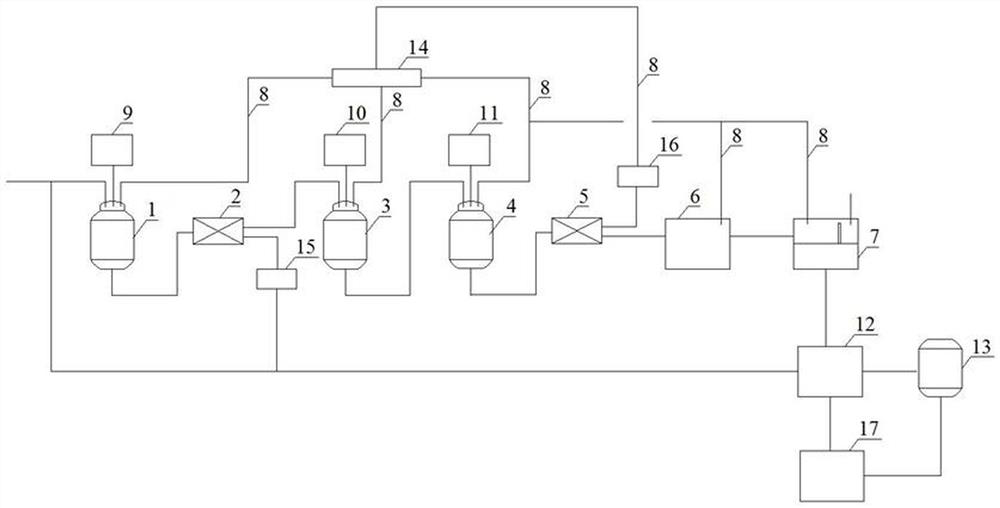

[0071] Such as figure 1 Shown: a method for preparing high-purity beryllium with industrial beryllium, under the protection of inert gas, comprises the following steps:

[0072] A. Alkali washing: put industrial beryllium into 10% sodium hydroxide aqueous solution, stir until completely dissolved, and obtain sodium beryllium acid solution;

[0073] B. primary filtration: the gained sodium beryllium acid solution is filtered to remove impurities such as Si, B and Cu therein (this part of the impurity is an impurity that does not react with OH-), to obtain a primary filtrate and a primary filter residue;

[0074] C. pickling: passing the gained primary filtrate into a 10% hydrochloric acid solution for reaction to obtain a beryllium chloride solution;

[0075] D. Precipitation: pass into excessive weak base in the gained beryllium chloride solution, generate the beryllium hydroxide solution with white precipitate;

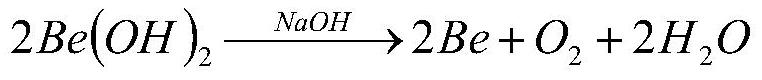

[0076] E. Secondary filtration: filter the obtained beryllium...

Embodiment 2

[0083] Based on embodiment 1, the difference of this embodiment is:

[0084] In step A, the concentration of aqueous sodium hydroxide solution is 20%;

[0085] In step C, the concentration of the hydrochloric acid solution is 20%;

[0086] In step F, place the obtained secondary filter residue at a constant temperature of 130°C and dry to obtain powdered beryllium hydroxide;

[0087] In step G, set the voltage to 3V.

Embodiment 1-2

[0089] Based on Embodiment 1-2, the difference of this embodiment is:

[0090] In step A, the concentration of aqueous sodium hydroxide solution is 13%;

[0091] In step C, the concentration of the hydrochloric acid solution is 15%;

[0092] In step F, place the obtained secondary filter residue at a constant temperature of 110°C and dry to obtain powdered beryllium hydroxide;

[0093] In step G, set the voltage to 2.9V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com