Device and method for detecting fault position of multi-mode optical fiber by using optical resonant cavity

A multi-mode optical fiber, fault location technology, applied in the direction of measuring devices, using re-radiation, re-radiation of electromagnetic waves, etc., can solve the problems of complex structure, high equipment requirements, and inability to meet at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

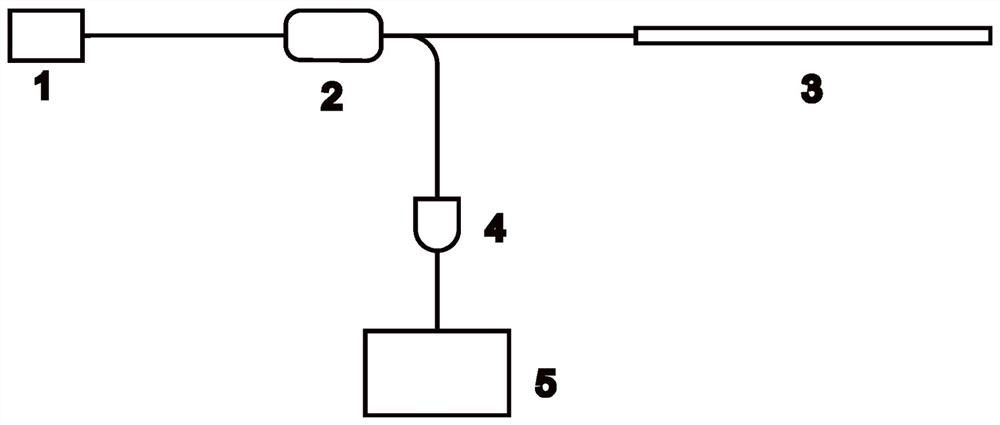

[0014] A detection device that utilizes an optical resonant cavity to realize the fault location of a multimode optical fiber, such as figure 1 As shown: it includes a semiconductor laser 1, a single-mode fiber coupler 2, a photodetector 4 and an oscilloscope 5. The semiconductor laser 1 itself does not have an isolator and has its own single-mode pigtail; the single-mode fiber coupler 2 Both ends are equipped with single-mode pigtails; the semiconductor laser 1 is connected to the left side of the single-mode fiber coupler 2 through the self-contained single-mode pigtails, and the one on the right side of the single-mode fiber coupler 2 A single-mode pigtail is connected to the multimode optical fiber 3 to be tested, and another single-mode pigtail is connected to the photodetector 4, and the photodetector 4 is connected to the oscilloscope 5 through a transmission cable, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com