Method for improving thermal stability and crystallization speed of Sb2Se phase change film

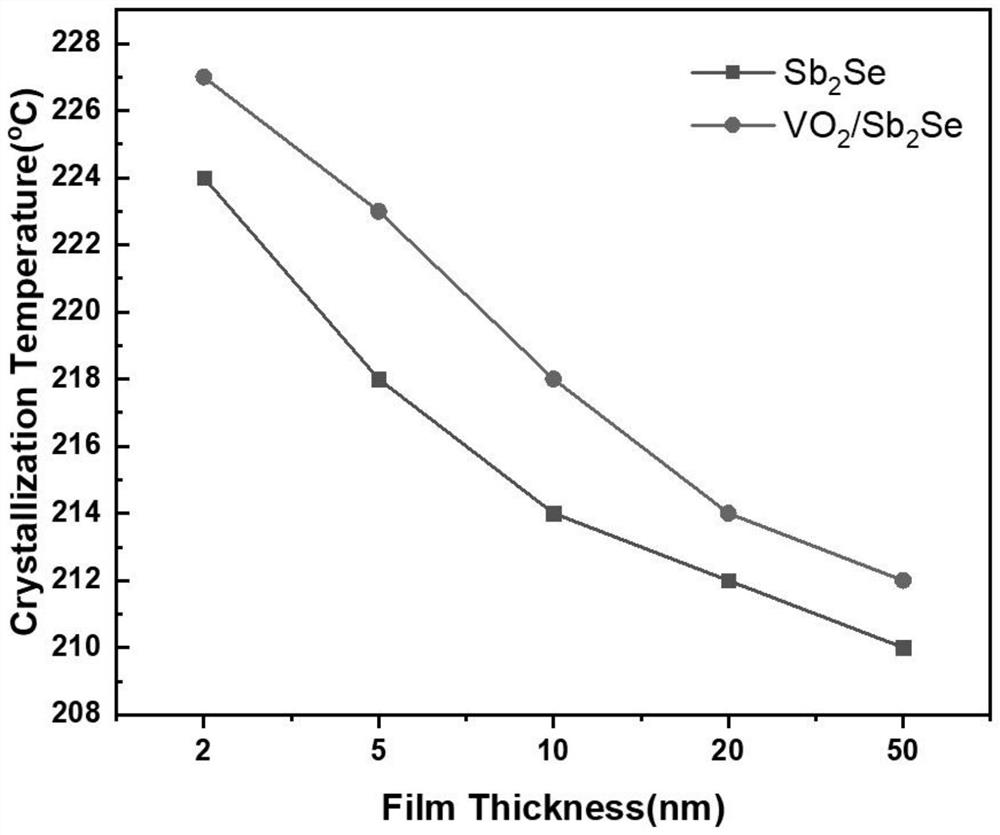

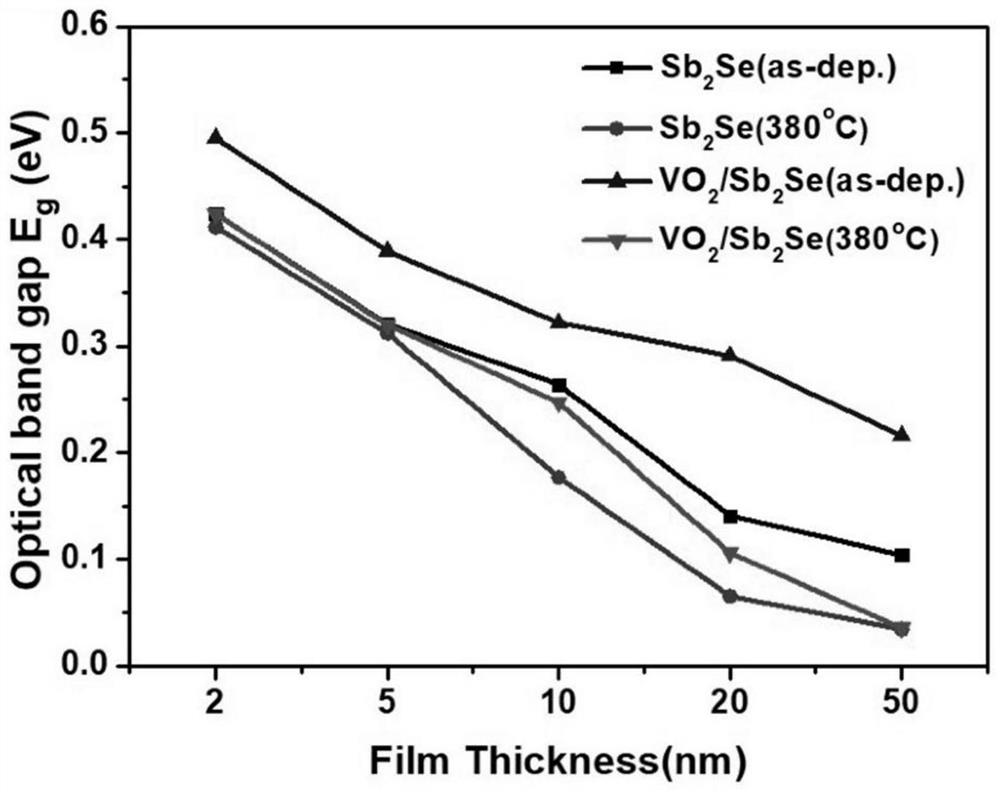

A technology of crystallization speed and thermal stability, applied in the field of microelectronics, which can solve the problems of differential thermal stability and low crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] 1. Specific steps

[0020] The preparation method is: use high-purity round block VO 2 and Sb 2 Se materials are used as targets. Use a magnetron sputtering device, use high-purity Ar gas as the working gas, and use SiO 2 / Si(100) is the substrate material for surface area deposition, the specific steps are as follows:

[0021] Step (1) respectively in Sb 2 Se round target and VO 2 The back of the round target is completely attached to a circular copper sheet with the same diameter as the target, and the thickness of the copper sheet is about 1mm to obtain a magnetron sputtering coating target; 2 The target is installed in a DC sputtering target, and the Sb 2 Se installed in the RF sputtering target;

[0022] Step (2) SiO 2 Put the / Si(100) substrate into deionized water and ultrasonically clean it for 15 minutes, then put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com