LED down lamp driving controller

A technology for driving controllers and LED downlights, applied to electrical components, etc., can solve problems such as low power factor, poor performance, and poor electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

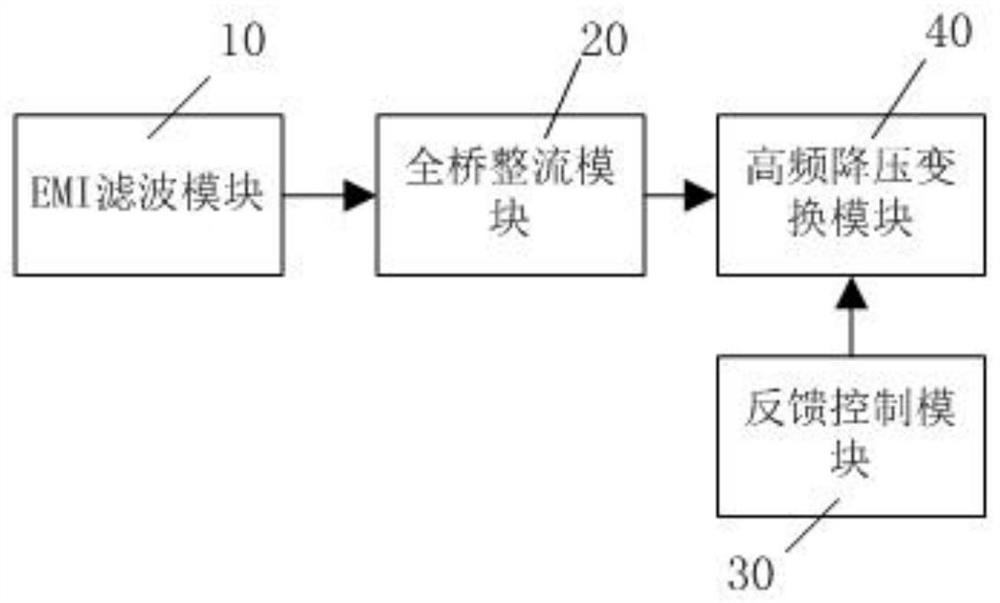

[0038] Such as figure 1 As shown, a LED downlight drive controller, including:

[0039] The EMI filtering module 10 is used to suppress common-mode interference signals and surge signals in the input AC mains, and send the processed input AC mains to the input end of the full-bridge rectifier module 20;

[0040] The full-bridge rectification module 20 is used to rectify the input AC mains power and output it as DC power, and then deliver the DC power to the primary winding of the high-frequency step-down conversion module 40;

[0041] The feedback control module 30 uses the OB3330X chip to perform feedback control and power factor correction on the primary winding of the high-frequency step-down conversion module 40, and simultaneously controls the shutdown of the field effect transistor Q1 of the high-frequency step-down conversion module 40;

[0042] The high-frequency step-down conversion module 40 is used for stepping down the rectified direct current, and outputting it t...

Embodiment 2

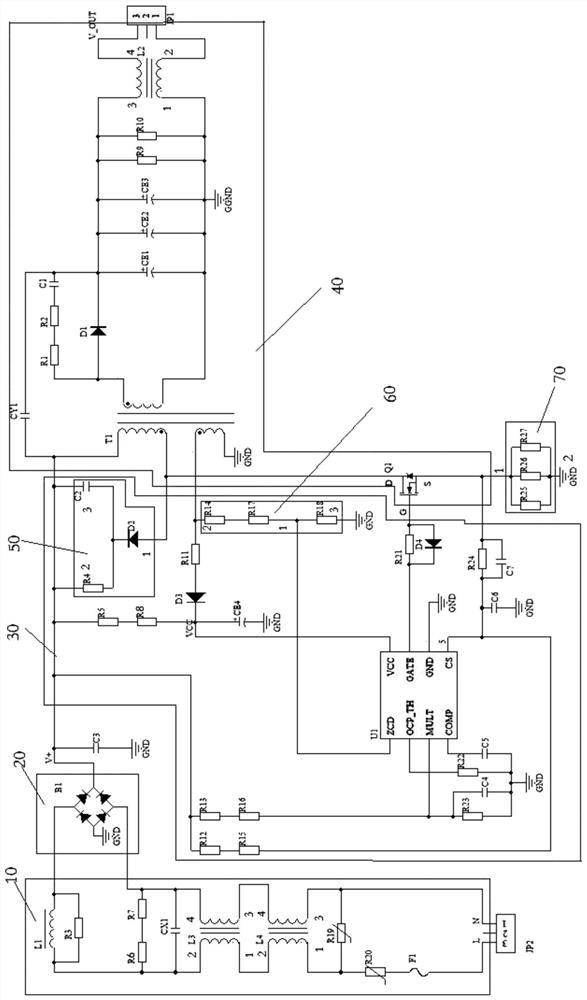

[0045] On the basis of Embodiment 1, the specific circuit structure of the device is as follows figure 2 As shown, the EMI filter module 10 includes a fuse F1, a twentieth resistor R20, a first inductor L1, a third inductor L3, a fourth inductor L4, a first safety capacitor CX1, a third resistor R3, a sixth resistor R6, The seventh resistor R7 and the nineteenth resistor R19, the third inductor L3 and the fourth inductor L4 are common mode inductors. The EMI filter module can play the role of lightning protection and surge protection. At the same time, it can effectively suppress the common-mode interference signal in the AC mains transmitted by the grid, suppress the interference radiation, improve the anti-electromagnetic interference ability of the system, and will not cause power grid interference. Fluctuation interferes with the normal operation of other instruments and equipment.

[0046] One end of the fuse F1 in the EMI filter module is connected to one end of the AC...

Embodiment 3

[0079] On the basis of Example 1 and Example 2, a 60Ω / 25W resistance was used as the load for the test, and the corresponding technical parameters were adjusted according to the actual situation. The relevant data obtained can show that the LED tube provided by this example The lamp drive controller can output constant current within the allowable error range when the AC input is between 100V and 240V. The maximum output voltage is 45V. It has constant current characteristics, protects the LED lamp, and has good electromagnetic compatibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com