Preparation method of cefixime side chain acid active ester

A technology of cefixime side chain acid and active ester, which is applied in the field of medicine, can solve the problems of low yield, long reaction time, and low production capacity, and achieve the effects of high product purity, simple operation, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] At 20°C, add 52g of cefixime side chain acid and 81gDM into a mixed solution of 250ml of dichloroethane and acetonitrile, the mass ratio of acetonitrile to dichloroethane is 1:7, add 7.2ml of triethylamine and 0.4ml of pyridine, lower the temperature to 8°C, add 41ml of triethyl phosphite dropwise, add dropwise for 2.5h, under the stirring condition of 200 rpm, use a microwave reactor, adjust the microwave insulation temperature to 15°C, and the microwave radiation power to 80W, The radiation time is 60min. The temperature was lowered to 3°C, and 68 g of cefixime side-chain acid active ester was obtained by suction filtration, with a yield of 96.57% (calculated as cefixime side-chain acid), a purity of 99.7%, and a content of more than 99.2%.

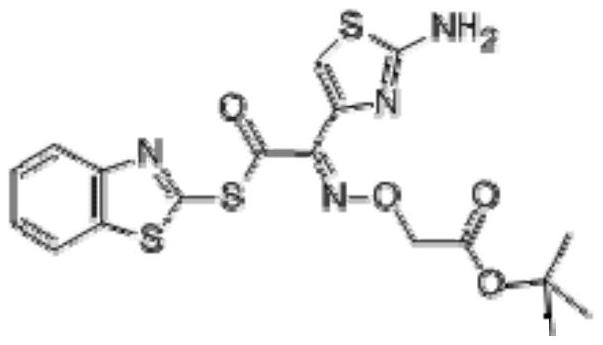

[0036] The structure of cefixime side chain acid active ester is characterized as follows:

[0037] Elemental analysis (%) measured value (calculated value)

[0038] C47.96 (48.00), H3.98 (4.00), N12.42 (12.44), S21.35 (21.33)....

Embodiment 2

[0040] At 25°C, add 52g of cefixime side chain acid and 81gDM into a mixed solution of 250ml of dichloroethane and acetonitrile, the mass ratio of acetonitrile to dichloroethane is 7:1, add 7.2ml of triethylamine and 0.4ml aniline, cool down to 10°C, add 41ml triethyl phosphite dropwise, add dropwise for 2.5h, under the stirring condition of 600 rpm, use a microwave reactor, adjust the microwave holding temperature to 20°C, and the microwave radiation power to 150W, The radiation time is 40min. The temperature was lowered to -2°C, and 69 g of cefixime side chain acid active ester was obtained by suction filtration, with a yield of 97.89% (based on cefixime side chain acid), a purity of 99.6%, and a content of more than 99.3%.

Embodiment 3

[0042] At 30°C, add 52g of cefixime side chain acid and 81g of DM into a mixed solution of 250ml of dichloroethane and acetonitrile, the mass ratio of acetonitrile to dichloroethane is 1:7, add 7.2mN,N-dichloroethane Methylaniline and 0.4ml aniline, lower the temperature to 15°C, add 41ml triethyl phosphite dropwise, add dropwise for 2.5h, under the stirring condition of 500 rpm, use a microwave reactor, adjust the microwave holding temperature to 25°C, microwave The radiation power is 200W, and the radiation time is 30min. The temperature was lowered to 1° C., and 70 g of cefixime side chain acid active ester was obtained by suction filtration, with a yield of 99.31% (based on cefixime side chain acid), a purity of 99.8%, and a content of more than 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com