A kind of transparent conductive hydrogel with single-sided self-adhesion and its preparation method and application

A transparent conductive and hydrogel technology, applied in the field of hydrogel, can solve problems such as poor mechanical properties and inconvenient assembly and operation, achieve strong safety, improve test accuracy, and ensure accurate capture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

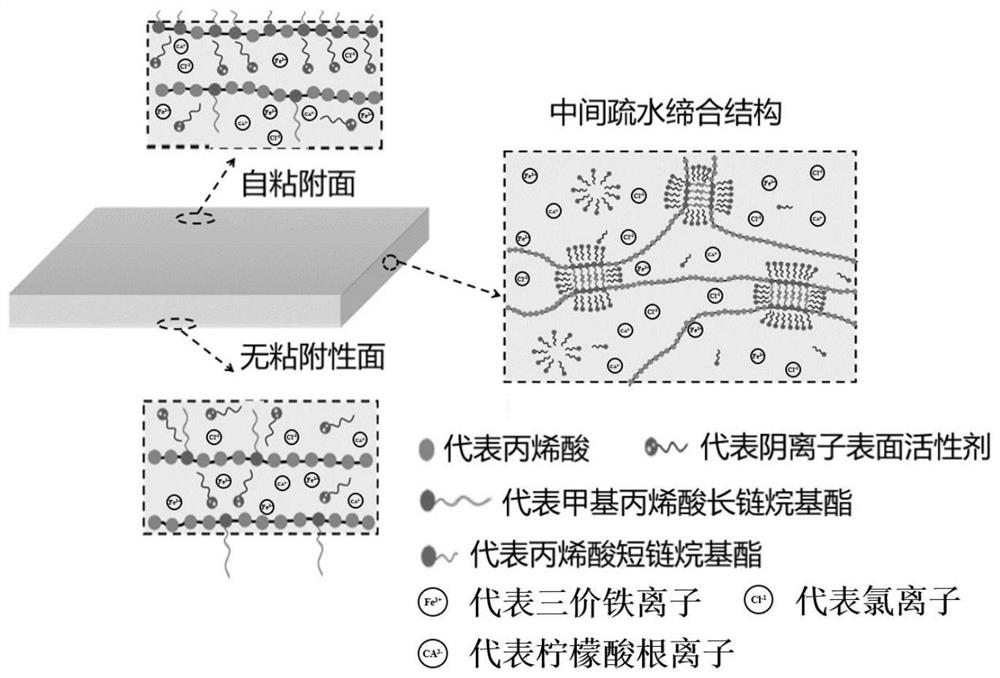

[0039] figure 1 It is a schematic structural diagram of the transparent conductive hydrogel with single-sided self-adhesion prepared by the present invention, and the specific preparation process is as follows:

[0040] 1. Add 5.5 g of sodium dodecyl sulfate (SDS) to 40 ml of deionized water, and magnetically stir at 800 rpm for 30 min at 25°C to obtain clear solution A;

[0041] 2. Add 1.75ml of dodecyl methacrylate (LMA) to solution A, stir magnetically for 3h at 500 rpm at 25°C; then add 10g of acrylic acid (AAc), at 25°C at 500 rpm Stir magnetically for 20 min at a speed of 500 rpm until it is completely dissolved, then add 80 mg of initiator ammonium persulfate and stir for 30 min, and finally add 300 μl of butyl acrylate (BA), stir magnetically for 20 min at a speed of 500 rpm, and mix well to obtain solution B ;

[0042] 3. The solution B was ultrasonically defoamed for 5 minutes, then poured into a glass mold (100mm*100mm*2mm), and reacted at 60°C for 6 hours to obta...

Embodiment 2

[0049] 1. Take 40ml of deionized water, add 5.0g of sodium dodecyl sulfate, and magnetically stir at 500 rpm for 25min at 25°C to obtain clear solution A;

[0050] 2. Add 1.75 ml of dodecyl methacrylate to solution A, stir magnetically at 500 rpm for 3 hours, then add 10 g of acrylic acid, stir magnetically at 500 rpm for 20 minutes until all dissolved, and then Add 90 mg of ammonium persulfate initiator and stir for 30 minutes, finally add 200 μl of butyl acrylate, stir magnetically for 15 minutes at a speed of 500 rpm, and mix well to obtain solution B;

[0051] 3. The solution B was ultrasonically defoamed for 5 minutes, then poured into a glass mold (100mm*100mm*2mm), and reacted at 60°C for 4h to obtain a hydrophobic association hydrogel with single-sided self-adhesion;

[0052] 4. Mix 500ml of 0.15mol / L ferric chloride aqueous solution and 500ml of 0.9mol / L citric acid aqueous solution to obtain solution C;

[0053] 5. The prepared hydrogel with self-adhesion on one sid...

Embodiment 3

[0056] 1. Take 40 ml of deionized water, add 4.0 g of sodium dodecyl sulfate, and magnetically stir at 500 rpm for 15 minutes at 25°C to obtain a clear solution A.

[0057] 2. Add 1.75ml of dodecyl methacrylate to solution A, stir magnetically at 500 rpm for 4 hours at 25°C, then add 10g of acrylic acid, magnetically stir at 500 rpm at 25°C Stir for 20 min until it is completely dissolved, then add 100 mg of potassium persulfate initiator, stir for 30 min, and finally add 100 μl of butyl acrylate, magnetically stir at 500 rpm for 15 min at 25°C, and mix well to obtain solution B;

[0058] 3. Ultrasonic defoaming of solution B for 5min, then poured into a glass mold (100mm*100mm*2mm), and reacted at 60°C for 8h to obtain a hydrophobic association hydrogel with single-sided self-adhesion;

[0059] 4. Mix 500ml of 0.2mol / L ferric chloride aqueous solution and 500ml of 1.2mol / L citric acid aqueous solution to obtain solution C;

[0060] 5. The prepared hydrogel with self-adhesion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com