Crosslinked polyethylene foam material and preparation method thereof

A technology of cross-linking polyethylene and polyethylene, applied in the field of polymer materials, can solve the problems of self-adhesion of products, expensive energy consumption of corona equipment, lower yield rate, etc. The effect of long maintenance time and high surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1, the preparation of vinylpyridine zinc salt

[0046] Dissolve 100 parts by mass of 4-vinylpyridine in 200 parts by mass of 95% ethanol, add 45 parts by mass of zinc chloride, carry out stirring reaction at 60°C for 12 hours, perform suction filtration, wash and dry with ethanol and ethyl acetate, That is, vinylpyridine zinc salt.

[0047]Step 2, preparation of cross-linked polyethylene foam material

[0048] 80 parts by weight of low density polyethylene, 10 parts by weight of vinylpyridine zinc salt, 10 parts by weight of ethylene-octene copolymer, 5 parts by weight of azodicarbonamide blowing agent, 1.5 parts by weight of zinc stearate, 1 part by weight of After mixing 1010 parts of antioxidants evenly, they are added to a single-screw extruder for extrusion, and the extrusion temperature is controlled at 95-125°C, the screw speed is 75rpm, and the die temperature is 125°C to obtain a master sheet with a thickness of 0.3mm; then, Pass the master sheet through...

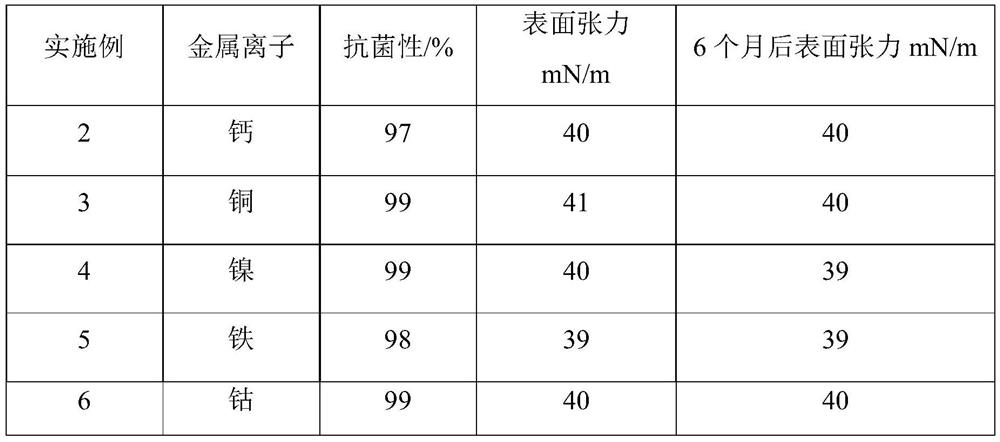

Embodiment 2~6

[0050] Except the following difference, all the other are the same as Example 1, select different metal salts to react.

[0051] Table 1

[0052]

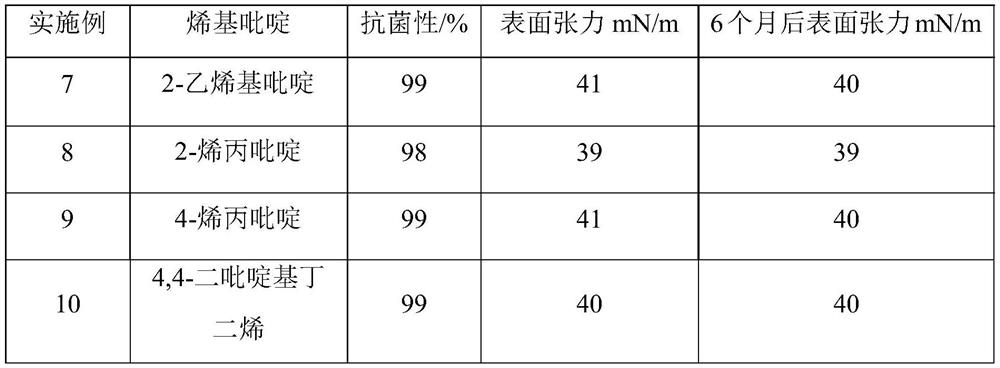

Embodiment 7~10

[0054] Except the following difference, all the other are the same as Example 1, select different alkenylpyridines to react.

[0055] Table 2

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com