Weather-resistant ultraviolet curing ink and preparation method thereof

An ultraviolet light and weather-resistant technology, applied in inks, household appliances, applications, etc., can solve problems such as poor weather resistance, and achieve the effects of improving interface bonding, improving stretching and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

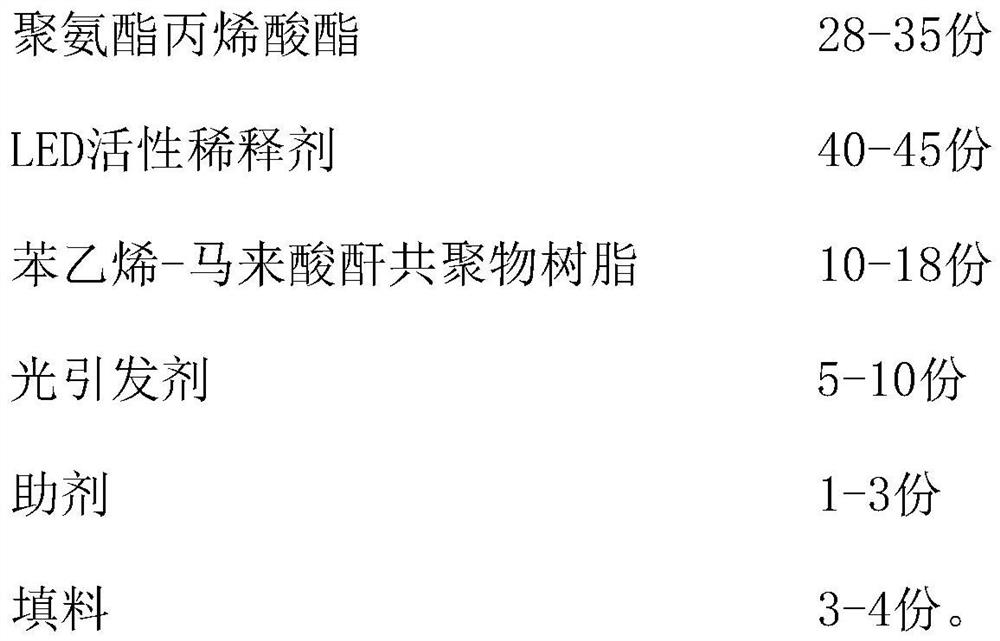

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of weather-resistant ultraviolet light curing ink, comprising the following steps:

[0025] Weigh each component according to the weight ratio in Table 1, mix and stir the styrene-maleic anhydride copolymer resin and polyurethane acrylate at 50°C, the stirring speed is 900r / min, and the stirring time is 25 minutes; continue to add LED active diluent 1. Photoinitiator, the stirring speed is 1000r / min, and the stirring time is 30 minutes; then add fillers and additives, and the stirring speed is 800r / min, and the stirring time is 80 minutes.

Embodiment 2

[0027] A preparation method of weather-resistant ultraviolet light curing ink, comprising the following steps:

[0028] Weigh each component according to the weight ratio in Table 1, mix and stir the styrene-maleic anhydride copolymer resin and polyurethane acrylate at 55°C, the stirring speed is 800r / min, and the stirring time is 20 minutes; continue to add LED active diluent 1. Photoinitiator, the stirring speed is 1100r / min, and the stirring time is 50 minutes; then add fillers and additives, and the stirring speed is 900r / min, and the stirring time is 60 minutes.

Embodiment 3

[0030] A preparation method of weather-resistant ultraviolet light curing ink, comprising the following steps:

[0031] Weigh each component according to the weight ratio in Table 1, mix and stir the styrene-maleic anhydride copolymer resin and polyurethane acrylate at 60°C, the stirring speed is 1000r / min, and the stirring time is 30 minutes; continue to add LED active diluent 1. Photoinitiator, the stirring speed is 1200r / min, and the stirring time is 60 minutes; then add fillers and additives, and the stirring speed is 1000r / min, and the stirring time is 100 minutes.

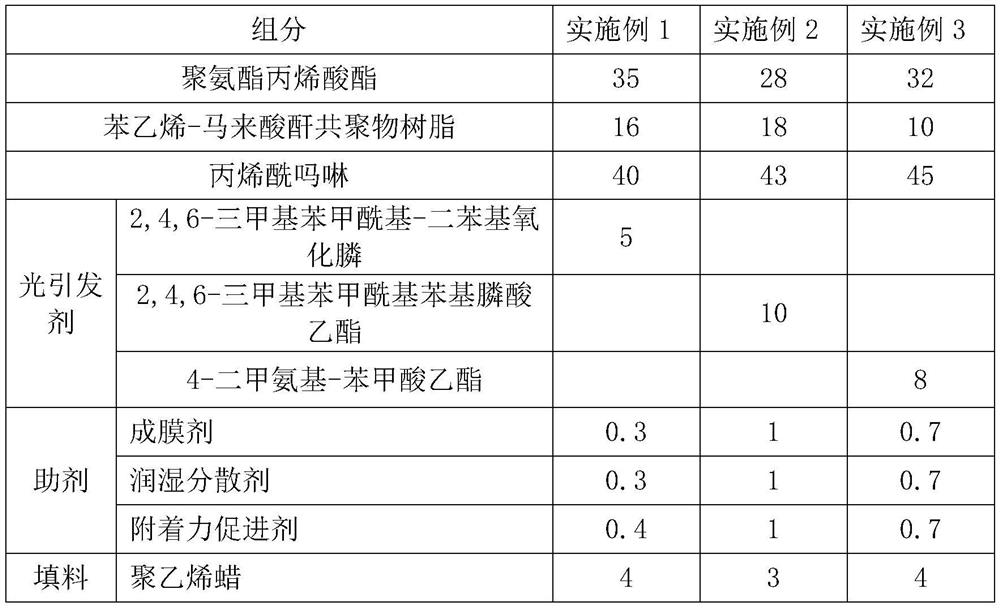

[0032] Table 1: Weight ratio of weather-resistant UV-curable inks in Examples 1-3

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com