Graphene/SiC composite particle enhanced metal-base composite material

A technology of composite particles and composite materials, applied in metal material coating technology, gaseous chemical plating, coating, etc., can solve problems such as insufficient fracture toughness, large surface energy, and hindering performance, and achieve improved interface bonding and increased dispersion Uniformity, the effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

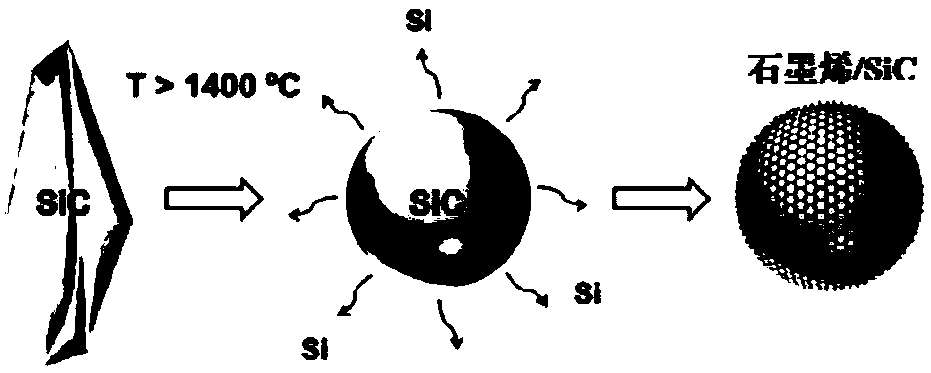

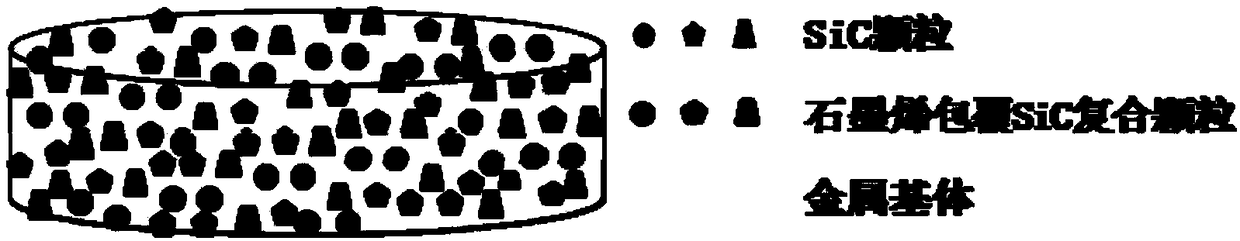

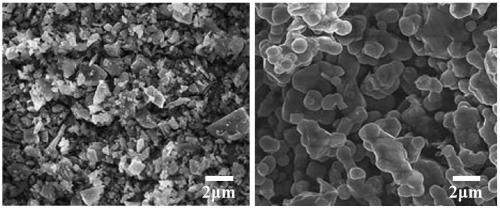

[0041] Graphene-coated SiC composite particles were prepared by pyrolyzing SiC in a vacuum environment. The schematic diagram is shown in figure 1 . The quality and thickness of graphene on the SiC surface can be controlled by controlling the temperature, vacuum degree and holding time. The electron micrographs of the graphene-coated SiC composite particles prepared by this method are shown in image 3 .

[0042] Mix the graphene-coated silicon carbide composite powder and metal powder evenly. During the mixing process, a high-energy ball mill can be used to wet-mix the graphene-coated SiC composite powder and aluminum powder in alcohol. The mixing speed is 500r / min. for 6h. After the powder mixing, place it in a vacuum drying oven and dry it at a temperature of 50 degrees, and then the mixed powder of graphene / SiC and aluminum is obtained. Figure 5 Shown is an electron micrograph of graphene-coated SiC composite powder mixed with aluminum powder by high-energy ball milling...

Embodiment 2

[0045] Graphene was deposited on the SiC surface by chemical vapor deposition. Put an appropriate amount of SiC powder into a chemical vapor deposition furnace, vacuumize it, and heat it up to a certain temperature (400-1200°C) under the protection of hydrogen or other inert gases; use hydrocarbons such as methane, ethylene or acetylene as carbon sources , with an appropriate amount of hydrogen, inert gas (nitrogen, argon) as the carrier gas, at an appropriate temperature (400-1200 ° C) or with plasma assistance for a certain period of time, the graphene deposition and growth. After the growth is over, the temperature is lowered under the protection of hydrogen (or argon, nitrogen). Electron microscope photos of graphene-coated SiC composite particles prepared by chemical vapor deposition are shown in Figure 4 .

[0046] The graphene-coated silicon carbide composite powder is uniformly mixed with the metal powder, and then the uniformly mixed powder is put into a mold, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com