Magnetron sputtering target gun with Halbach permanent magnet structure

A magnetron sputtering, permanent magnet technology, applied in sputtering coating, cathode sputtering application, application of magnetic film to substrate, etc., can solve the problem of large target gun, inability to grow strong magnetic materials, insufficient magnetic field strength, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

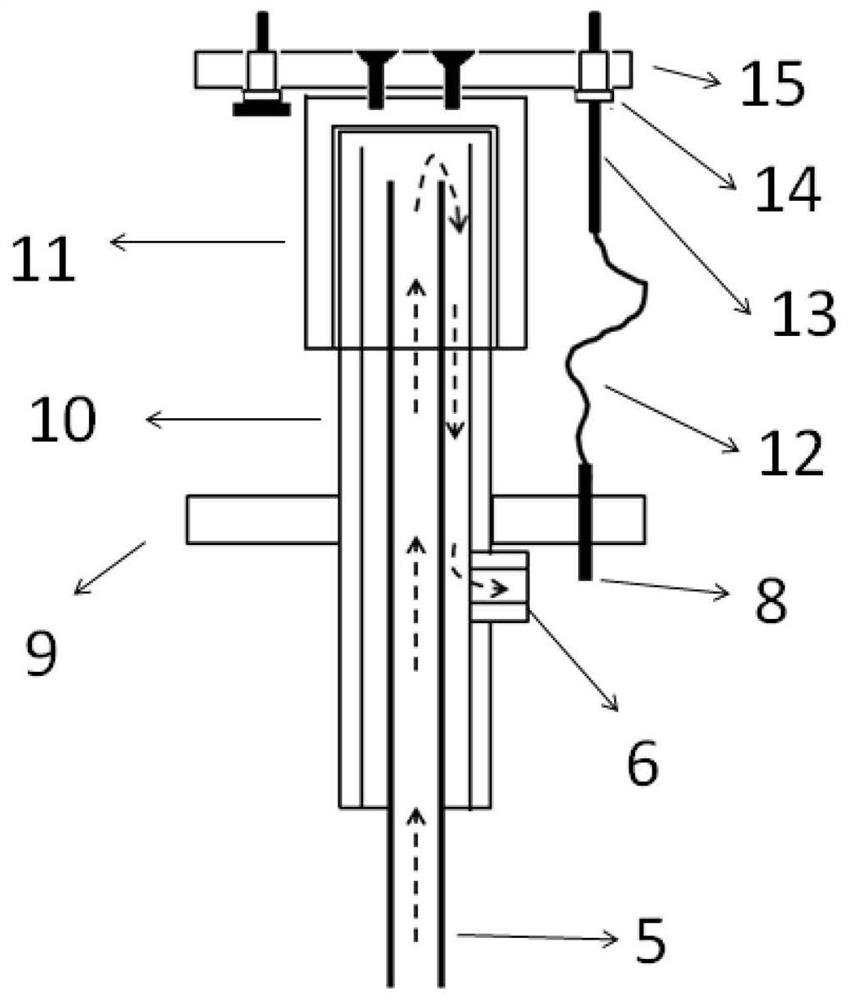

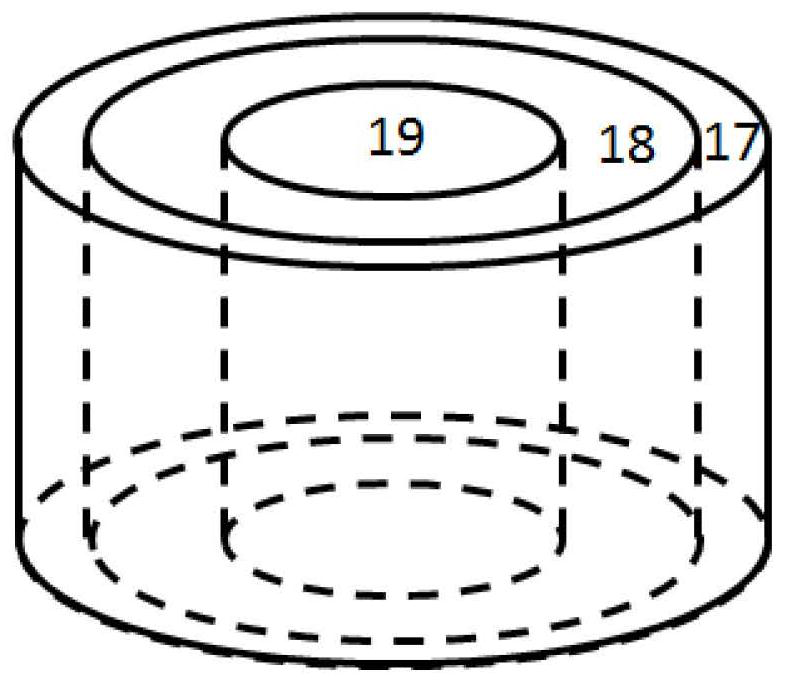

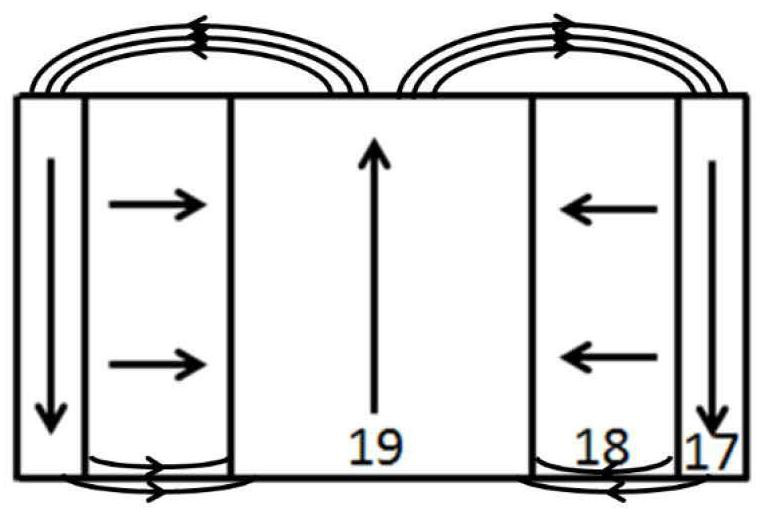

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] In the figure, 1 is the base, 2 is the ceramic insulating plate, 3 is the magnetic target, 4 is the target cover, 5 is the cooling water inlet, 6 is the cooling water outlet, 7 is the radio frequency connector, 8 is the vacuum ceramic seal electrode , 9 is a flange, 10 is a stainless steel tube, 11 is an oxygen-free copper cold head, 12 is a wire, 13 is a screw rod, 14 is a ceramic insulated terminal, 15 is an oxygen-free copper connector, 16 is a magnetic target base, 17 It is permanent magnet 1, and 18 is permanent magnet 2, and 19 is permanent magnet 3, and 20 is target material.

[0032] In order to make the structure, features and advantages of the present invention clearer, the magnetron sputtering target gun of the present invention will be described in more detail with reference to the accompanying drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com